Method and device used for preventing cavitation of chilling water pump in process of preparing propylene from coal-based methanol

A technology of methanol to propylene and process water, applied in pump components, liquid variable capacity machinery, pulse balance and other directions, can solve the problems of oil-water separation troubled devices running smoothly, insufficient water/heavy hydrocarbon residence time, and hydrocarbon compressor inlet temperature. Advanced problems, to achieve the effect of improving the oil-water separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

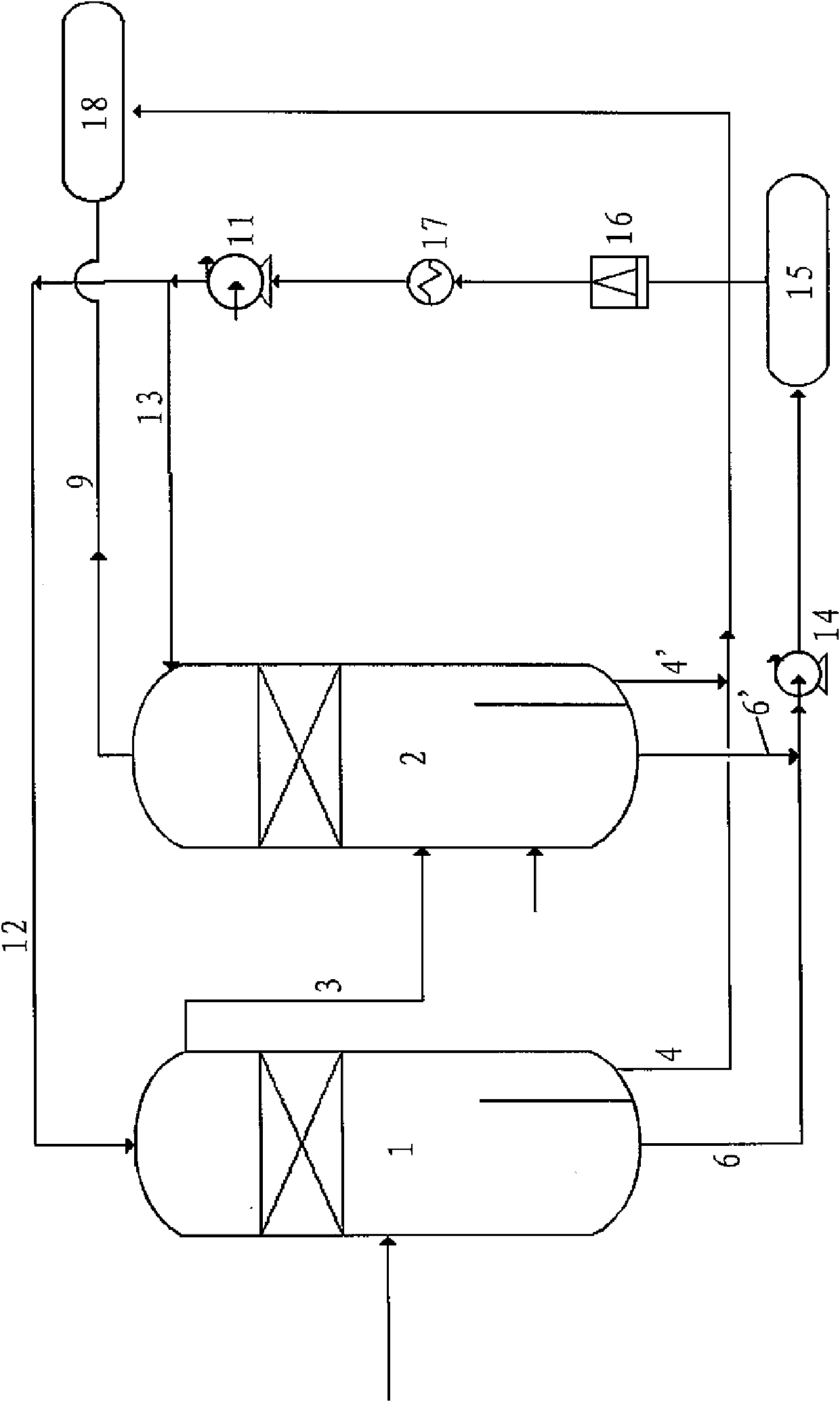

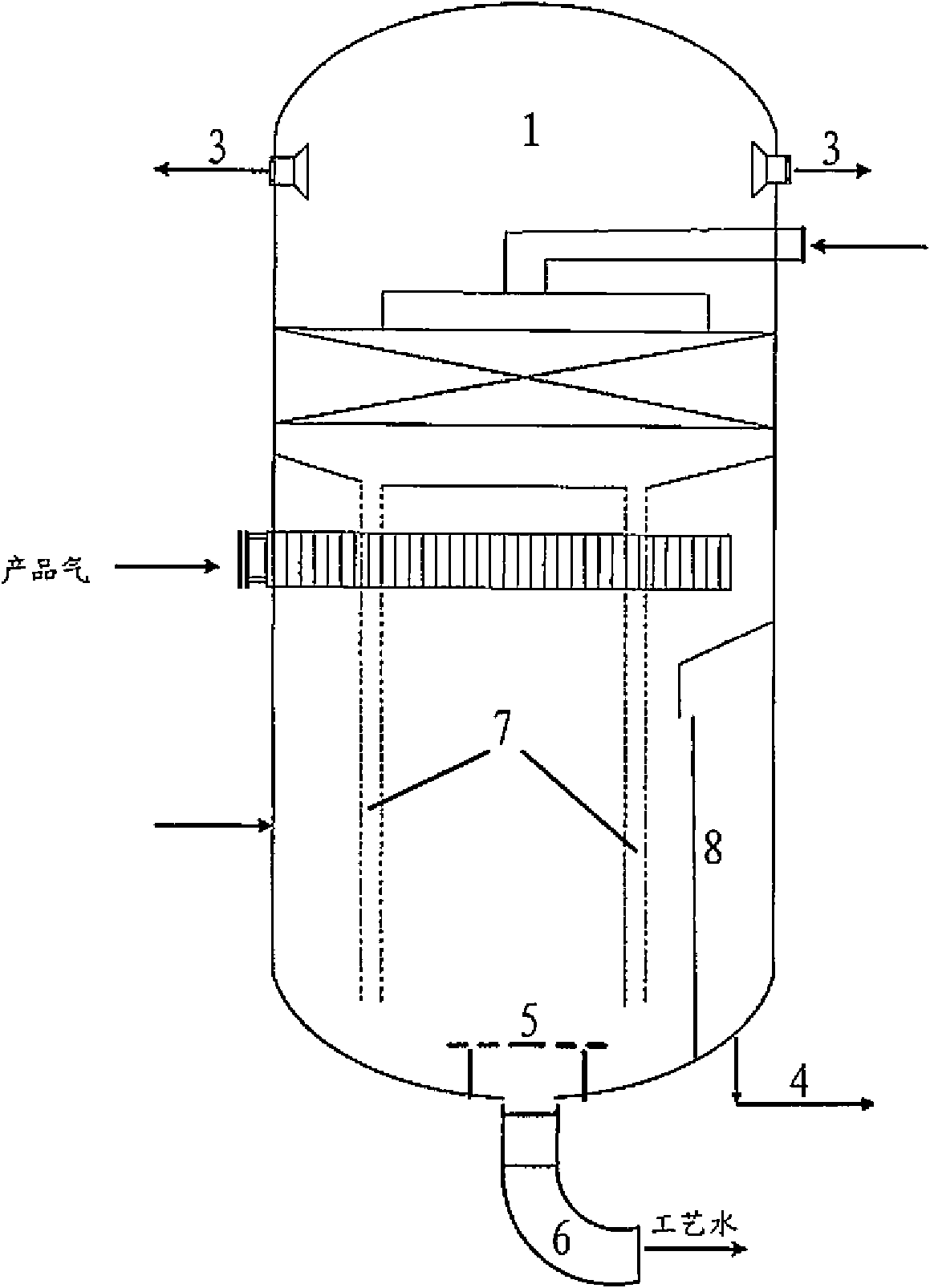

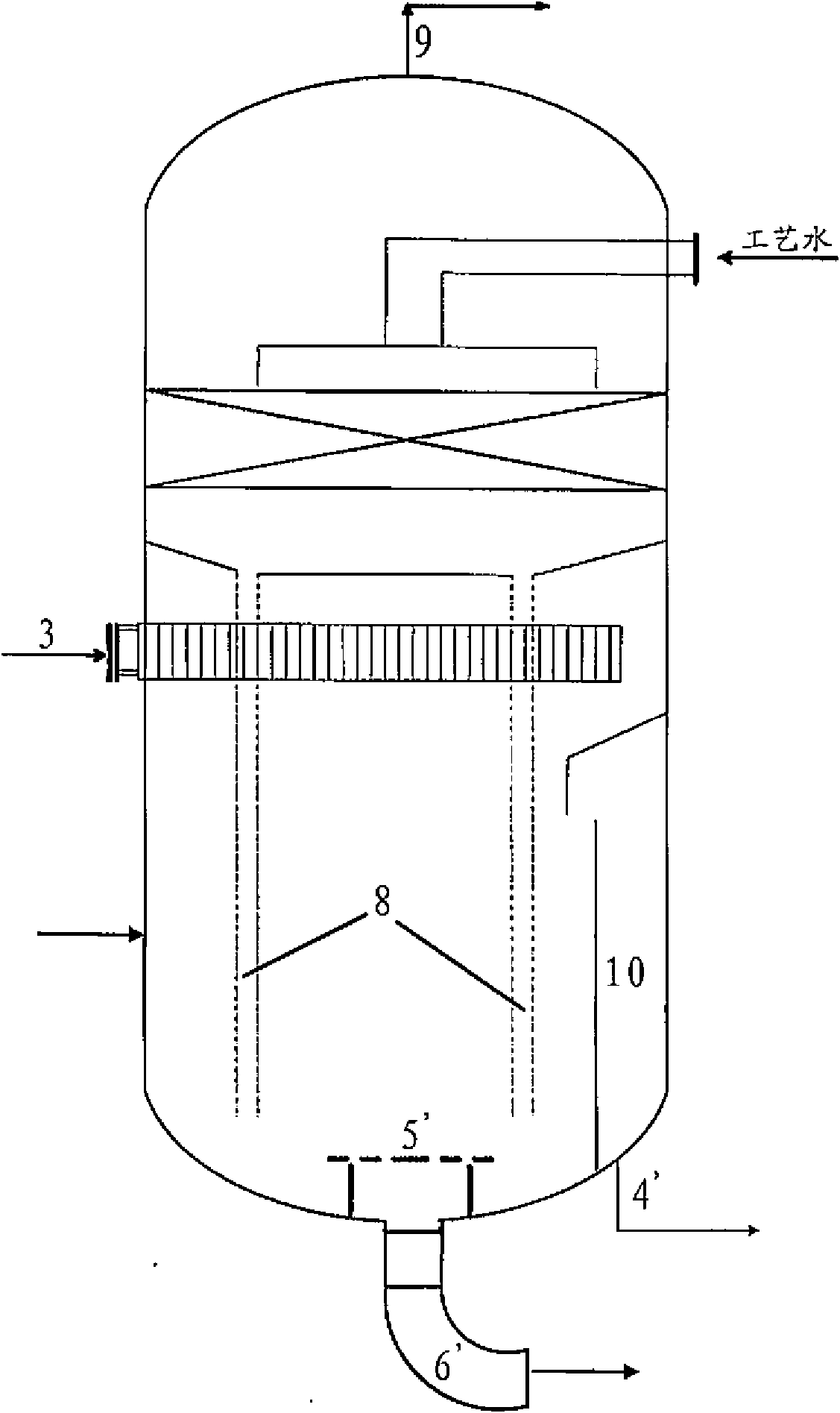

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0026] In the coal-based methanol-to-propylene process (MTP), the main function of the pre-chilling tower and the quenching tower is to separate the water and hydrocarbons in the product gas of the MTP reactor. Such as Figure 1-3 As shown, the cooled MTP reactor outlet product gas first enters the pre-chill cooling tower 1, and under the action of the process water injected from the top of the tower, part of the water and heavy hydrocarbons are condensed, and then reach the tower through the downcomer 7 of the collector. bottom. Water and heavy hydrocarbons are separated by sedimentation to form a water / heavy hydrocarbon interface. When the liquid level of the heavy hydrocarbon is higher than the overflow tank 8, the heavy hydrocarbon overflows to the hydrocarbon side to realize water / heavy hydrocarbon separation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com