Super-hydrophobic cotton yarn material for oil-water separation as well as preparation method and application thereof

A technology of oil-water separation and super-hydrophobicity, which is applied in the chemical industry, can solve the problem of low oil-water separation performance, and achieve the effects of improving practical applicability, good anti-fouling performance, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

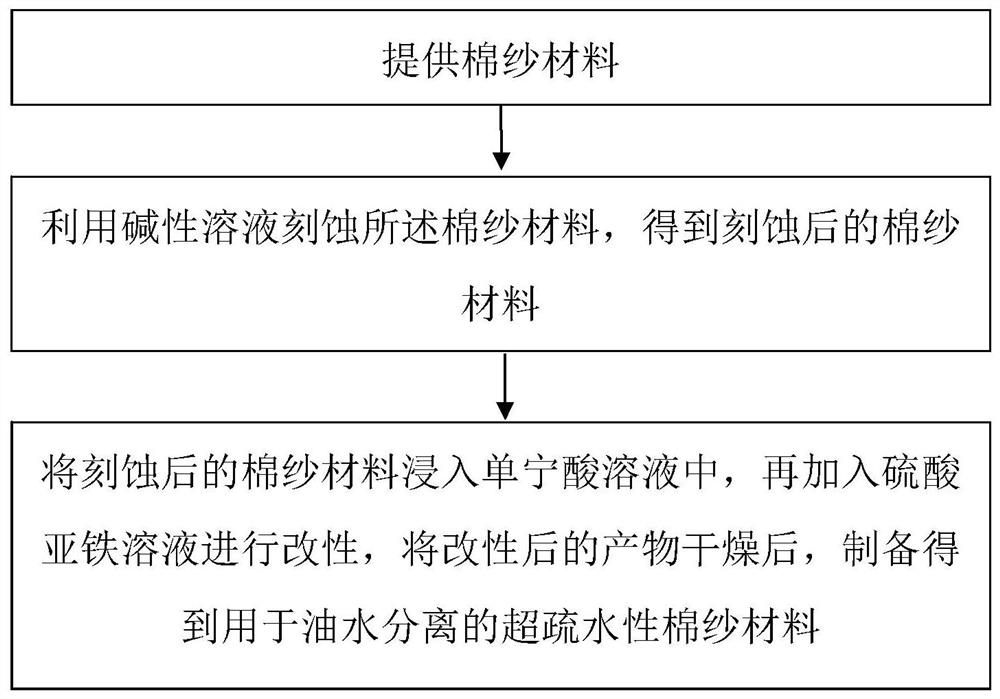

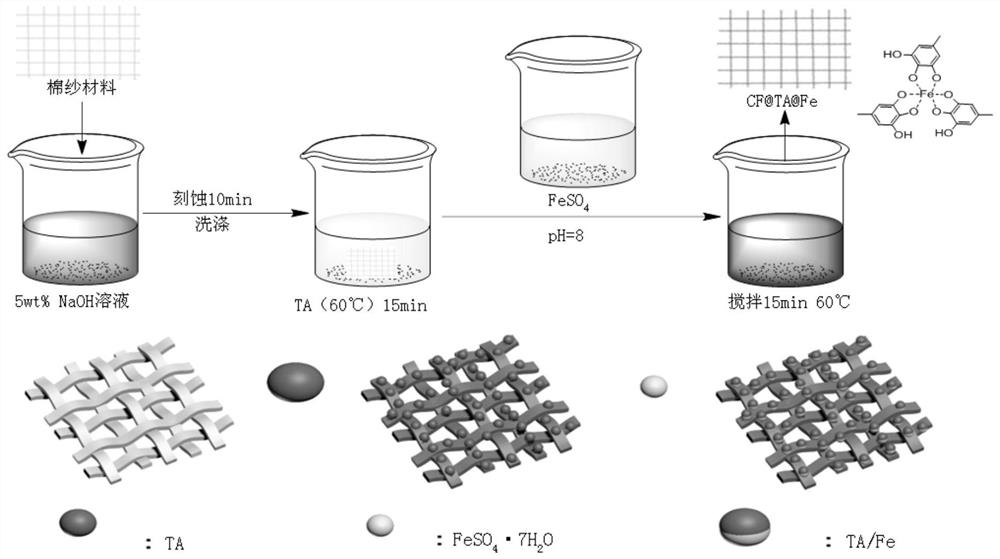

[0062] see figure 2 , to prepare superhydrophobic cotton yarn material (modified cotton yarn material) for oil-water separation

[0063] (1) Rinse the raw cotton yarn fabric with a size of 60mm*60mm successively with an appropriate amount of ethanol and ultrapure water, and let it dry naturally;

[0064] (2) Put the dried cotton fabric into 50ml 5wt% NaOH solution, stir at room temperature for 10min, and obtain the etched cotton fabric (CY);

[0065] (3) The configuration concentration is the tannic acid solution (TA) of 50mmol / L and the FeSO of 45mmol / L 4 ·7H 2 O solution;

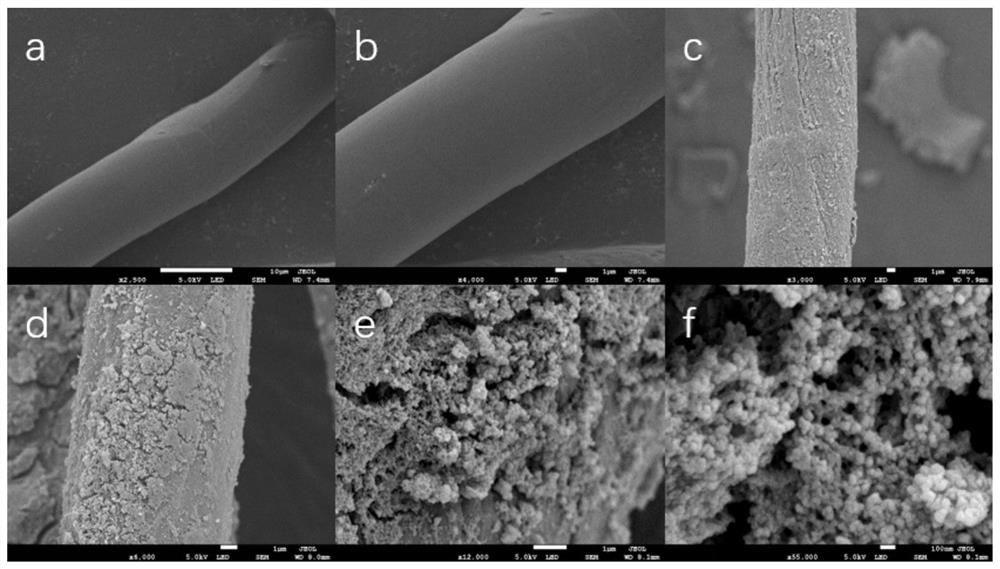

[0066] Immerse the etched cotton fabric into 50ml of tannic acid solution, react at 60°C for 15min, and then add FeSO 4 ·7H 2 O solution, reacted at 60°C for 15min, took it out, washed it with ultrapure water, and dried it in a vacuum oven at 120°C for 1h to obtain a superhydrophobic cotton yarn material for oil-water separation (TA / Fe@CY, where TA / Fe is Coral reef-like rough structure formed by th...

Embodiment 2

[0070] The hydrophobicity, oil-water separation performance, self-cleaning and reusability of the superhydrophobic cotton yarn material used for oil-water separation prepared in Example 1 were tested.

[0071] (1) Superhydrophobic performance test under different pH conditions

[0072] (1.1) Prepare a solution with a pH range from 1 to 10 with ultrapure water, sodium hydroxide, and hydrochloric acid, drop it on the surface of the superhydrophobic cotton material, and test the contact angle. Such as Figure 4 It was shown that within a certain pH range, the superhydrophobic cotton yarn material used for oil-water separation has superhydrophobicity, and the contact angle is generally higher than 150°.

[0073] (2) Self-cleaning test

[0074] (2.1) Under the same test conditions, the cleanability test of the methylene blue dye on the surface of the original cotton material and the superhydrophobic cotton yarn material used for oil-water separation was washed with ultrapure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com