Phenyl-reinforced flexible silicon dioxide aerogel as well as preparation method and application thereof

A technology of silica and phenyltriethoxysilane, which is applied in the field of airgel, can solve the limitation of the application range of flexible silica airgel, poor thermal stability and flame retardancy of flexible silica airgel and other problems, to achieve the effect of improving rigidity, increasing compressive strength, and connecting tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

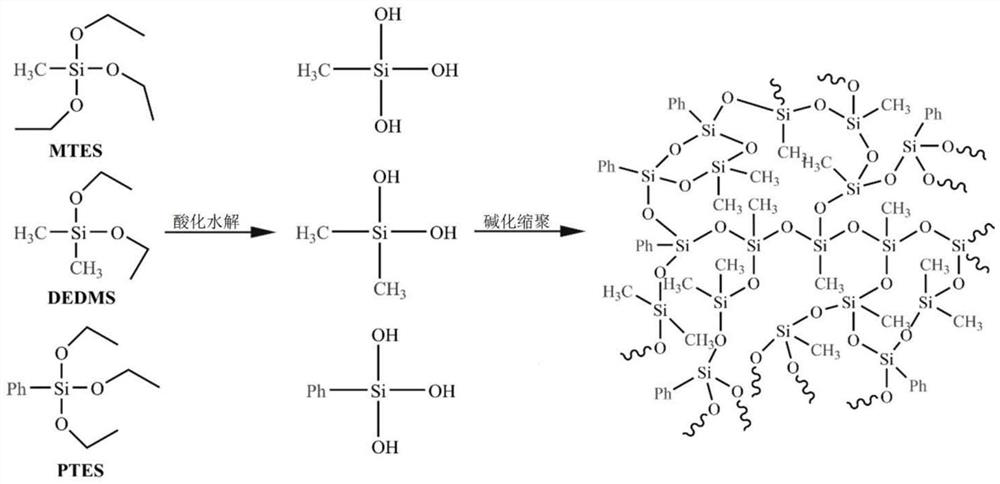

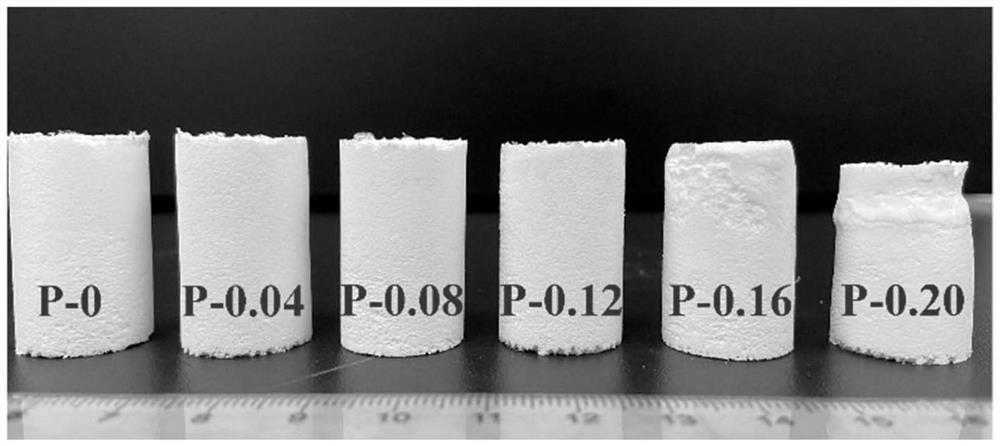

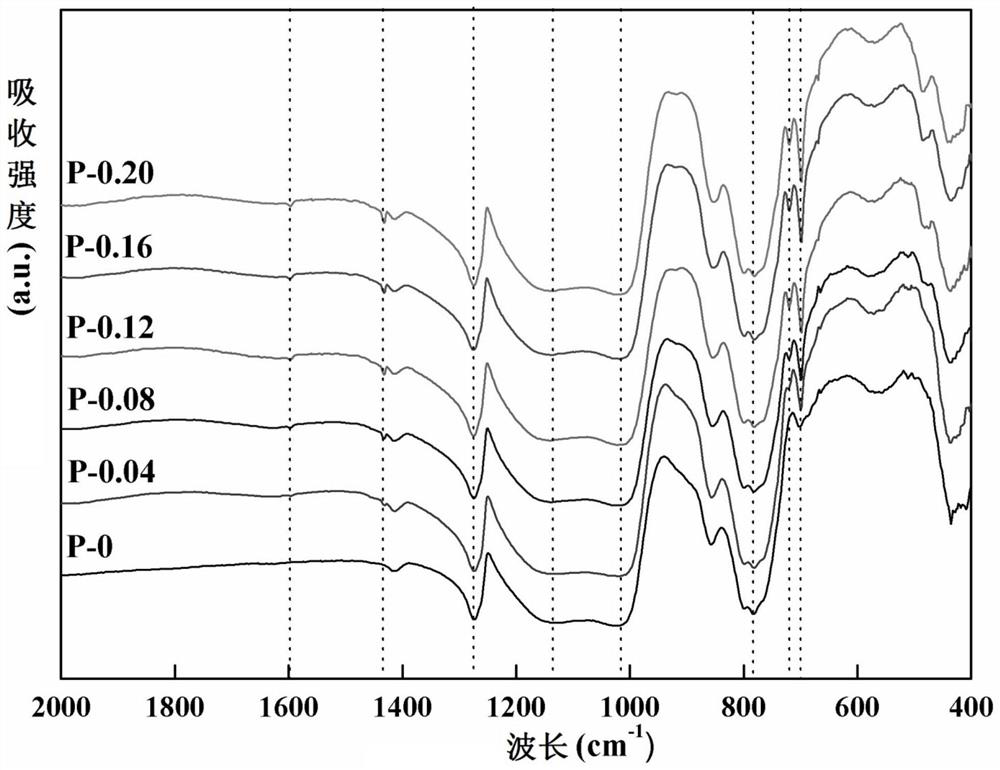

[0042] Example 1, a phenyl-reinforced flexible silica airgel is prepared by a sol-gel method using a mixture of a first silicon source and a second silicon source as a precursor, and the first silicon source is phenyl tri Ethoxysilane PTES, the second silicon source is methyltriethoxysilane MTES and dimethyldiethoxysilane DEDMS, the methyltriethoxysilane MTES, dimethyldiethoxy The molar ratio of silane DEDMS and phenyltriethoxysilane PTES is 1:0.38:0.12. Its preparation method comprises the following steps:

[0043] Step 1, prepare materials according to the above-mentioned phenyl-reinforced flexible silica airgel. Acetic acid is used for acidification hydrolysis, and urea is used for alkalization polycondensation. The molar ratio of each component is MTES:DEDMS:PTES=1:0.38:0.12.

[0044] Step 2, acidification and hydrolysis, 1g of cetyltrimethylammonium bromide CTAB is dissolved in 15ml of acetic acid solution with a concentration of 1mol / L under stirring conditions to obta...

Embodiment 2

[0047] Example 2 is different from Example 1 in that the molar ratio of PTES to MTES is 0.04, the rest is the same as Example 1, and the obtained phenyl-reinforced silica airgel is recorded as P-0.04.

Embodiment 3

[0048] Example 3 is different from Example 1 in that the molar ratio of PTES to MTES is 0.08, the rest is the same as Example 1, and the obtained phenyl-reinforced silica airgel is recorded as P-0.08.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com