Method for coating surface of underwater oleophobic net film with nano-material

A technology of nano-materials and omentum, applied in separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve the problems of cumbersome preparation process, easy pollution of the membrane surface, short service life, etc., to achieve Effects of cost reduction, surface hydrophilicity, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

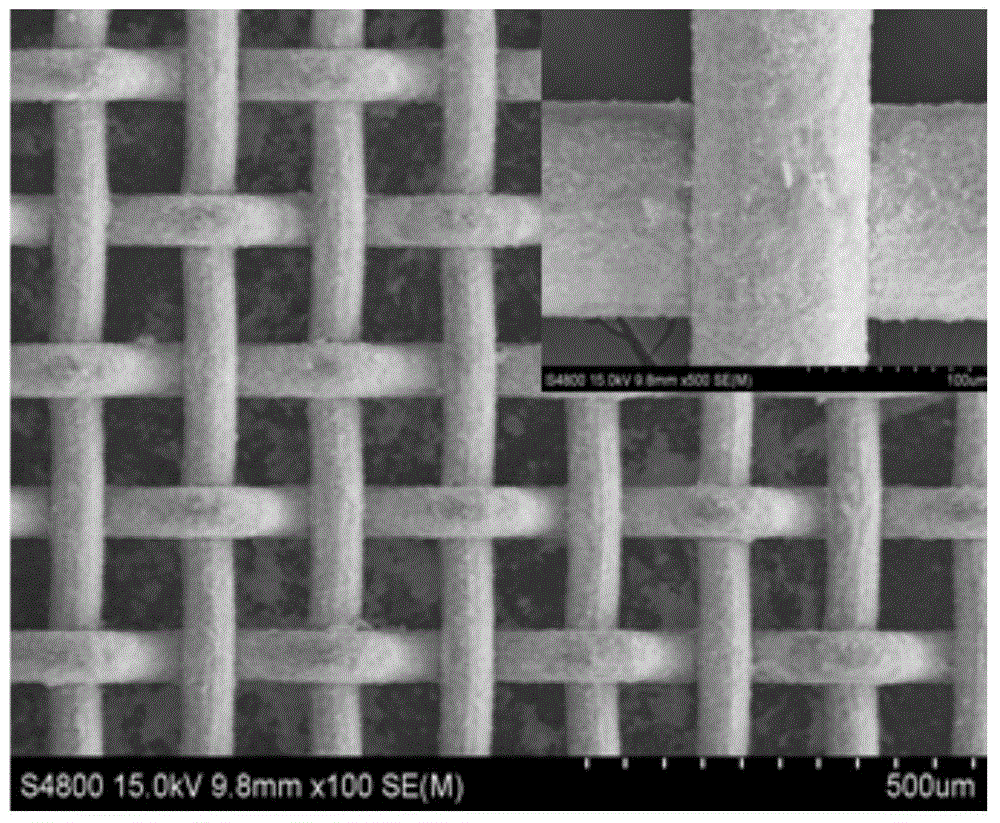

[0030] (1) Cleaning of the omentum: Select a stainless steel mesh membrane with a mesh number of 80, soak it in acetone and ultrasonically clean it for 5 minutes, take it out for rinsing, put it in anhydrous ethanol for ultrasonic cleaning for 5 minutes, take it out and rinse it, and put it in deionized water for ultrasonic cleaning Wash for 5 minutes, dry in an oven at 60°C for 12 hours and set aside;

[0031] (2) Chemical etching of omentum: soak the cleaned stainless steel mesh membrane in 0.2mol / L (CuCl 2 ) 2 ·H 2 O solution for 3 minutes, take it out and ultrasonically clean it in distilled water for 30 minutes, and then dry it in an oven at 90°C for 1 hour before use;

[0032] (3) Chemical modification of the omentum: immerse it in 2 mg / mL polydienyl propylene dimethyl ammonium chloride (PDDA) solution for 10 min, take it out, rinse it with deionized water, and dry it with nitrogen flow to obtain the modified omentum. Non-toxic stainless steel mesh membrane;

[0033]...

Embodiment 2

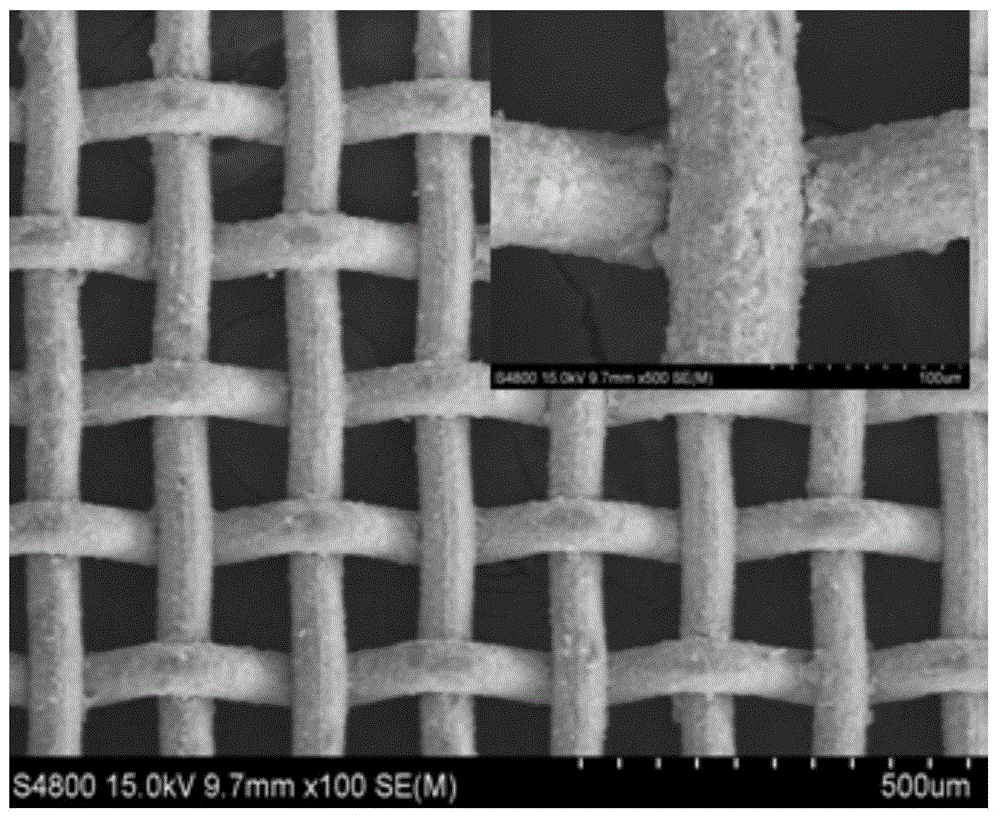

[0040](1) Cleaning of omentum: Select stainless steel mesh membrane with 100 meshes, soak it in acetone and ultrasonically clean it for 5 minutes, take it out and rinse it, put it in absolute ethanol for ultrasonic cleaning for 5 minutes, take it out and rinse it, put it in deionized water Ultrasonic cleaning for 5 minutes, drying in an oven at 60°C for 12 hours for use;

[0041] (2) Chemical etching of the omentum: Soak the cleaned stainless steel wire mesh in the mixed solution (3mL of phosphoric acid, hydrochloric acid and hydrogen peroxide, add 12g of ferric chloride in 45mL of deionized water), take it out after 5min Ultrasonic cleaning in distilled water for 30 minutes, and then drying in an oven at 60°C for 1 hour for use;

[0042] (3) Chemical modification of the omentum: then immerse it in a 5 mg / mL polyetherimide (PEI) solution for 15 minutes, take it out, rinse it with deionized water, and dry it with nitrogen flow to obtain a modified stainless steel mesh membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com