Preparation method of oil-water separation material

An oil-water separation and sponge technology, applied in the field of nanomaterials, can solve the problems of poor mechanical strength and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention discloses a preparation method of an oil-water separation material, comprising the following steps:

[0029] Soaking the sponge material in the graphene oxide solution, taking out the obtained sponge material and centrifuging to obtain the graphene oxide-coated sponge material;

[0030] The graphene oxide-coated sponge material is subjected to a reduction reaction under the action of a reducing agent to obtain an oil-water separation material.

[0031] The invention obtains the graphene oxide-coated sponge material by soaking, dipping, and centrifuging; then, under the action of a reducing agent, the graphene oxide-coated sponge material is reduced to obtain an oil-water separation material, that is, a reduced graphene oxide-coated sponge material. Cover with sponge.

[0032] According to the present invention, the graphene oxide is preferably prepared according to the following method:

Embodiment 1

[0045] Weigh 5.00g of graphite flakes and 3.75g of NaNO 3 In a 1L beaker, slowly add 150mL of concentrated sulfuric acid, and mechanically stir for 0.5h. Slowly add 20g KMnO in 0.5h 4 , After continuing to stir for 20h, stop stirring. A purplish red solution with a small amount of flakes was obtained. The solution was allowed to stand for 5 days with occasional manual stirring. Slowly add 500mL deionized water, then slowly add 30mL H 2 o 2 , to obtain a reaction solution containing graphene oxide.

[0046] The reaction solution was centrifuged at 10,000 rpm for 10 min, the supernatant was poured off, washed and centrifuged with deionized water repeatedly for 4 times, and a graphene oxide solid product was obtained.

[0047] Disperse the graphene oxide solid in deionized water, centrifuge at 6000rpm for 10min, collect the supernatant, add water to disperse the lower precipitate and centrifuge again (centrifuge at 6000rpm for 10min), and collect the supernatant again. Rep...

Embodiment 2

[0051] Cut the polymer sponge into cube samples of 2cm*2cm*2cm size, wash and dry, soak in 10mL0.2mg / mL graphene oxide solution, take it out and centrifuge at 1000rpm for 5 minutes to obtain the oxidized Graphene coated sponge;

[0052] The graphene oxide-coated sponge sample block was soaked in 50 mL of hydriodic acid aqueous solution with a mass concentration of 30%, and heated to 85° C. for reduction to obtain a reduced graphene oxide-coated sponge;

[0053] The reduced graphene oxide-coated sponge is cleaned and dried to obtain a redox graphene-based sponge.

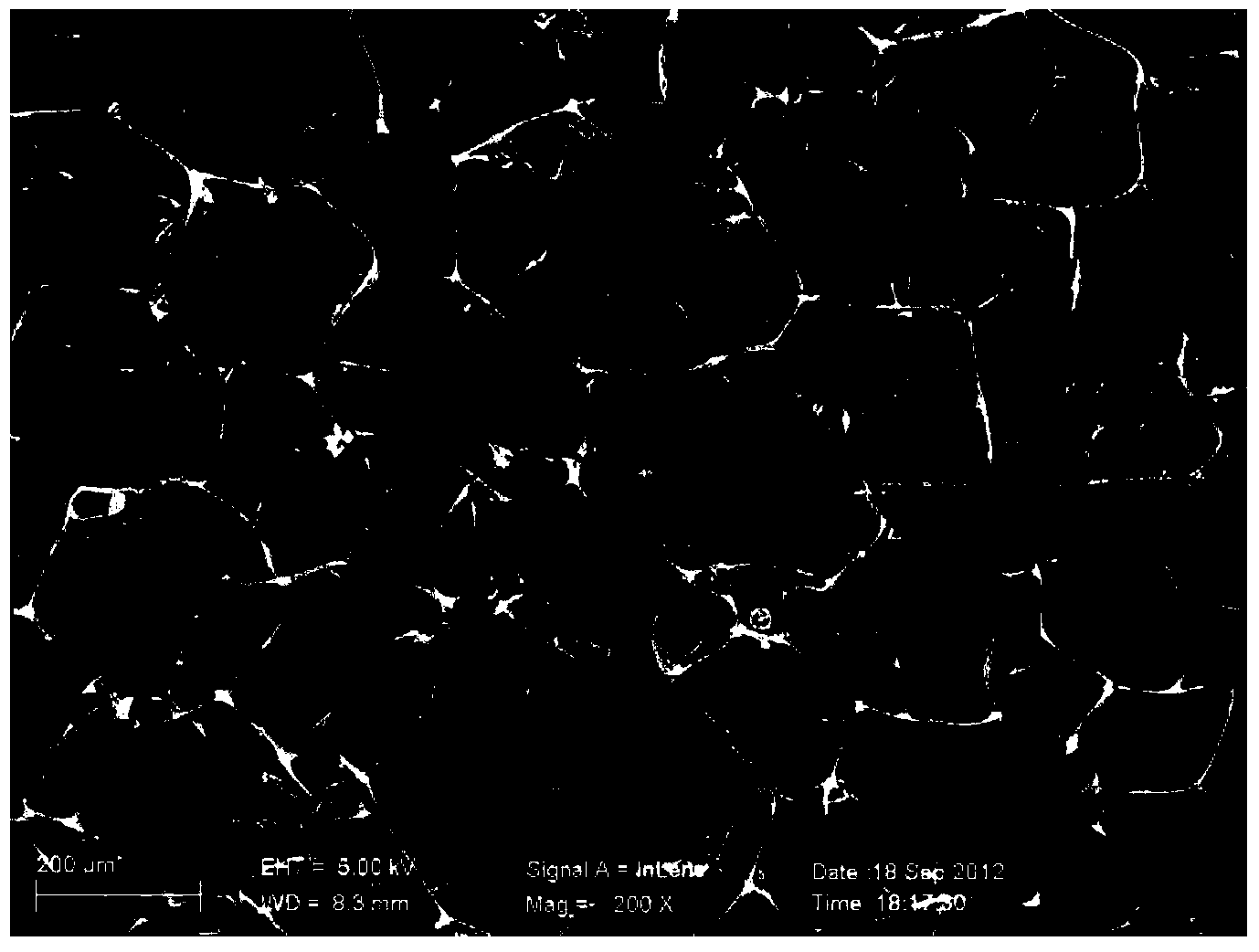

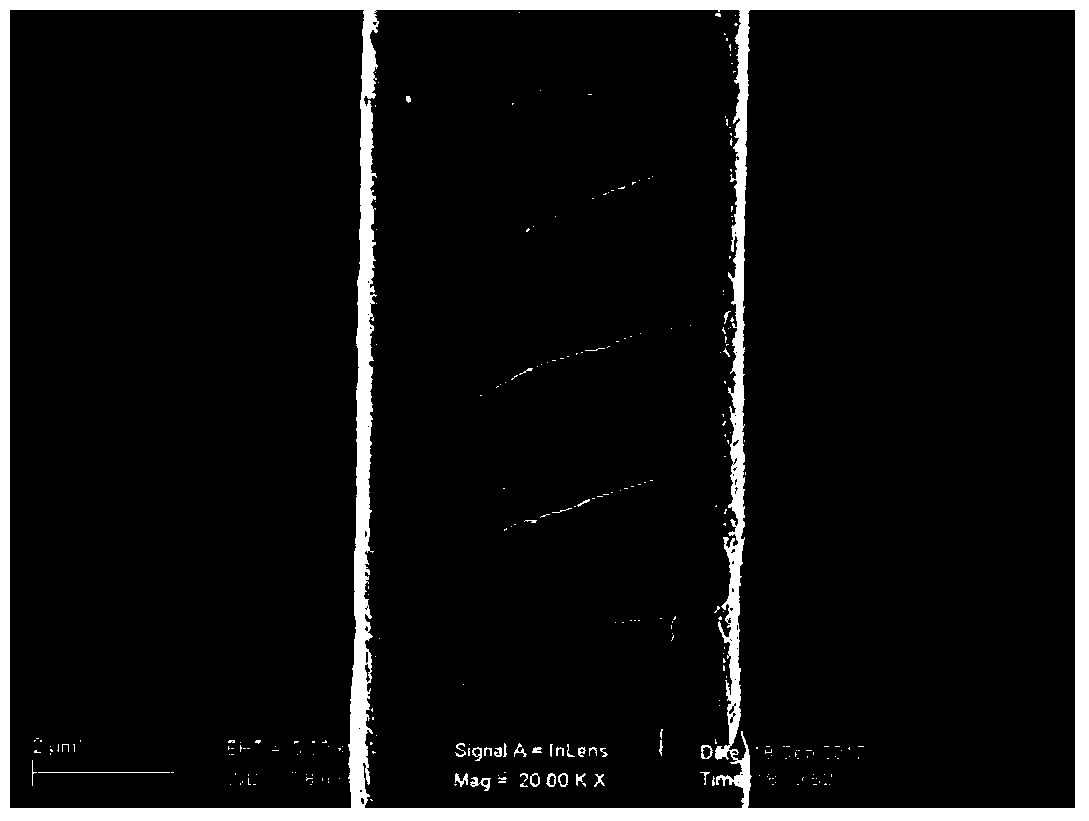

[0054] Field emission scanning electron microscope observation is carried out to described polymer sponge and reduced graphene oxide coated sponge, the results can be found in figure 2 and image 3 , figure 2 and image 3 The scanning electron micrographs of the polymer sponge and the reduced graphene oxide coated sponge provided by Example 2 of the present invention are obtained by figure 2 and image 3 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com