Super-oleophylic and super-hydrophobic sponge for oil-water separation, and preparation method and application of super-oleophylic and super-hydrophobic sponge

A technology for superhydrophobic sponge and oil-water separation, which is applied in the field of super-lipophilic and super-hydrophobic sponge for oil-water separation and its preparation, can solve the problems of complex preparation process, short time-consuming, high raw material price, etc., and achieves easy availability of raw materials and reduced surface energy, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

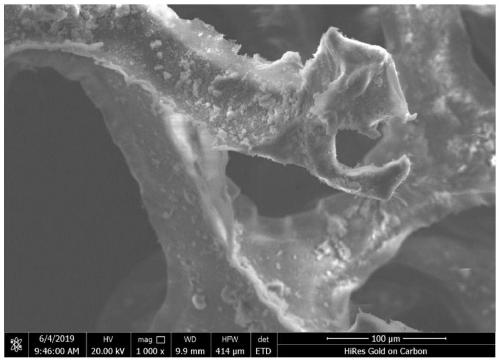

[0034] Step 1, add 1 gram of nano silicon dioxide to 100 grams of xylene, then add 0.01 gram of silane coupling agent KH-550, and stir at 60° C. for 2 hours to obtain a xylene dispersion of silicon dioxide;

[0035] Step 2, adding 2 grams of methyl MQ silicone resin to the xylene dispersion of silicon dioxide, stirring at 60°C for 1 hour to obtain a hydrophobic dispersion containing silicon dioxide and methyl MQ silicone resin;

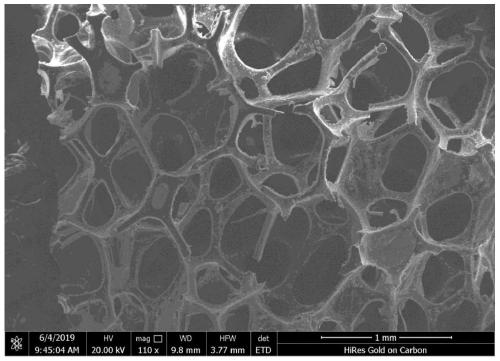

[0036] Step 3. Dip-coat the cleaned and pretreated polyurethane sponge in a hydrophobic dispersion containing silicon dioxide and methyl MQ silicone resin for 10 minutes, drain and dry naturally for 1 hour, and then place it in a blast drying oven at 40°C Bake down for 16 hours to obtain a super-oleophilic and super-hydrophobic sponge for oil-water separation.

Embodiment 2

[0038] Step 1, add 5 grams of nano silicon dioxide to 100 grams of toluene, then add 0.1 grams of silane coupling agent KH-560, and stir at 30 ° C for 4 hours to obtain a toluene dispersion of silicon dioxide;

[0039] Step 2, adding 10 grams of methylphenyl MQ silicone resin to the toluene dispersion of silicon dioxide, stirring at 40°C for 2 hours to obtain a hydrophobic dispersion containing silicon dioxide and methylphenyl MQ silicone resin;

[0040] Step 3, dip-coat the cleaned and pretreated melamine sponge in a hydrophobic dispersion containing silicon dioxide and methylphenyl MQ silicone resin for 10 minutes, drain and dry naturally for 1 hour, and then place it in a blast drying oven Bake at 80°C for 8 hours to obtain a super-oleophilic and super-hydrophobic sponge for oil-water separation.

Embodiment 3

[0042] Step 1, add 1 gram of nano silicon dioxide to 100 grams of benzene, then add 0.02 grams of silane coupling agent KH-570, and stir at 60°C for 2 hours to obtain a benzene dispersion of silicon dioxide;

[0043]Step 2, adding 10 grams of vinyl MQ silicone resin to the benzene dispersion of silicon dioxide, stirring at 50°C for 1.5 hours to obtain a hydrophobic dispersion containing silicon dioxide and vinyl MQ silicone resin;

[0044] Step 3. Dip the cleaned and pretreated polyurethane sponge into the hydrophobic dispersion containing silicon dioxide and vinyl MQ silicone resin for 10 minutes, drain and dry naturally for 1 hour, and then place it in a blast drying oven at 60°C Bake down for 12 hours to obtain a super-oleophilic and super-hydrophobic sponge for oil-water separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

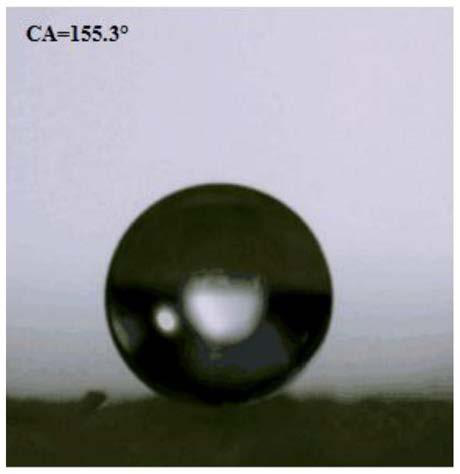

| contact angle | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com