Marine diesel engine oil composition and preparation method and application thereof

A technology of marine diesel engine and oil composition, applied in lubricating composition, petroleum industry and other directions, can solve the problems of unfriendly environment and many components, and achieve the effect of excellent oil-water separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

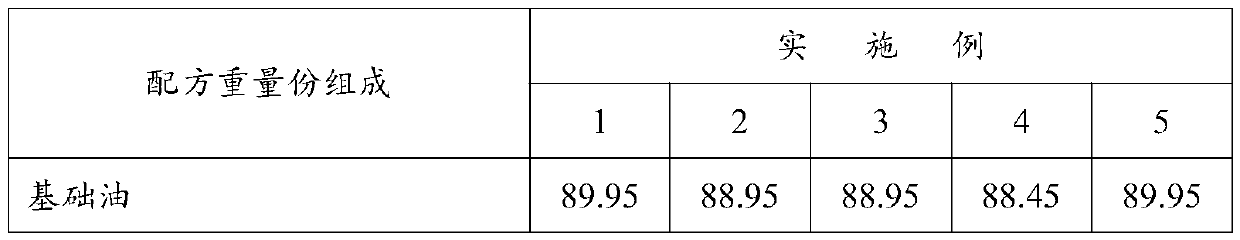

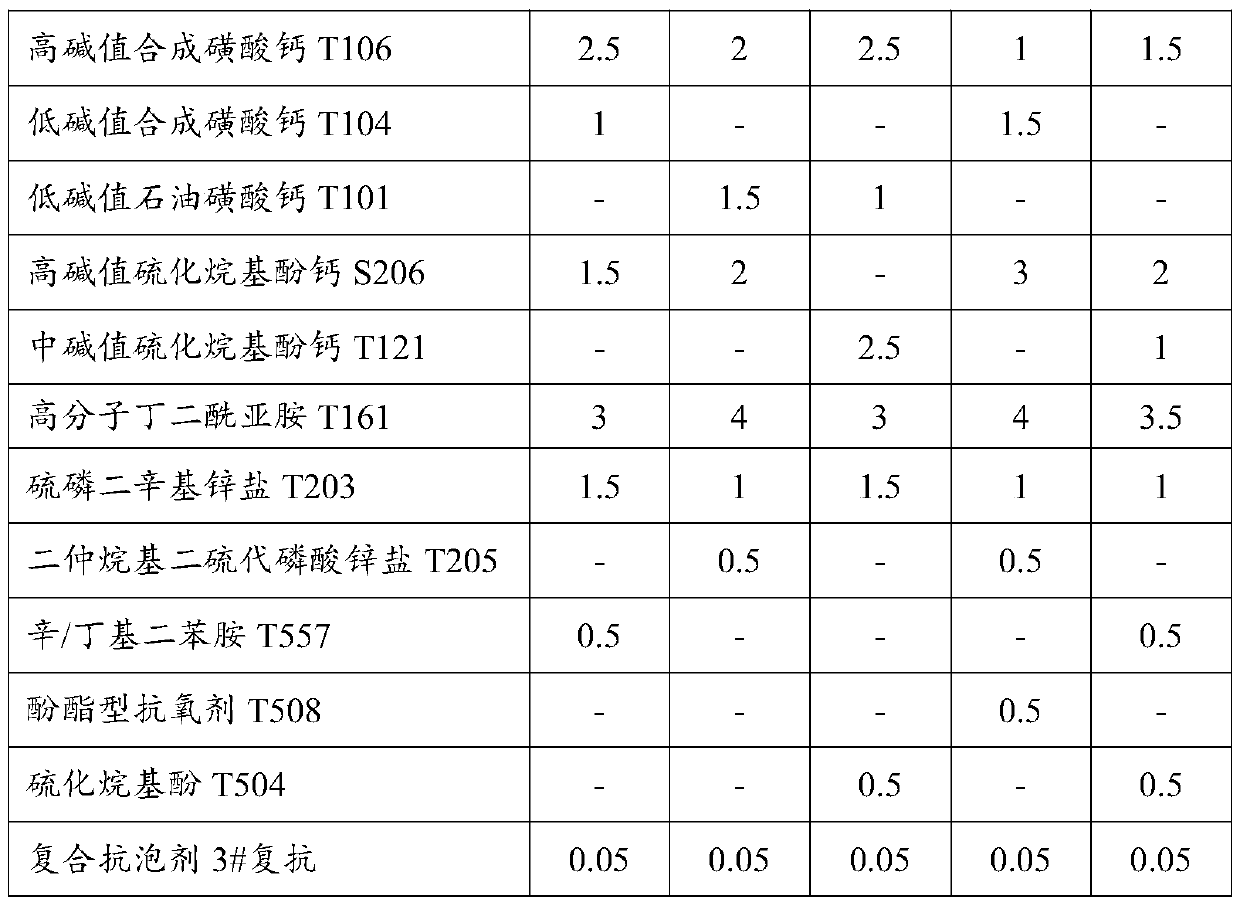

[0021] Embodiment 1 discloses a specific embodiment of a marine diesel engine oil composition, in parts by weight, consisting of the following components:

[0022] Detergent: high alkali value synthetic calcium sulfonate T1062.5 parts, low alkali value synthetic calcium sulfonate T1041 parts, high alkali value sulfurized calcium alkylphenate S2061.5 parts;

[0023] Dispersant: polymer succinimide T1613 parts;

[0024] Antioxidant: 1.5 parts of phosphodioctyl zinc salt T203, 0.5 parts of octyl / butyl diphenylamine T557;

[0025] Antifoaming agent: composite antifoaming agent 3# complex anti-0.05 part;

[0026] Base oil: 89.95 parts, the base oil is specifically mineral oil.

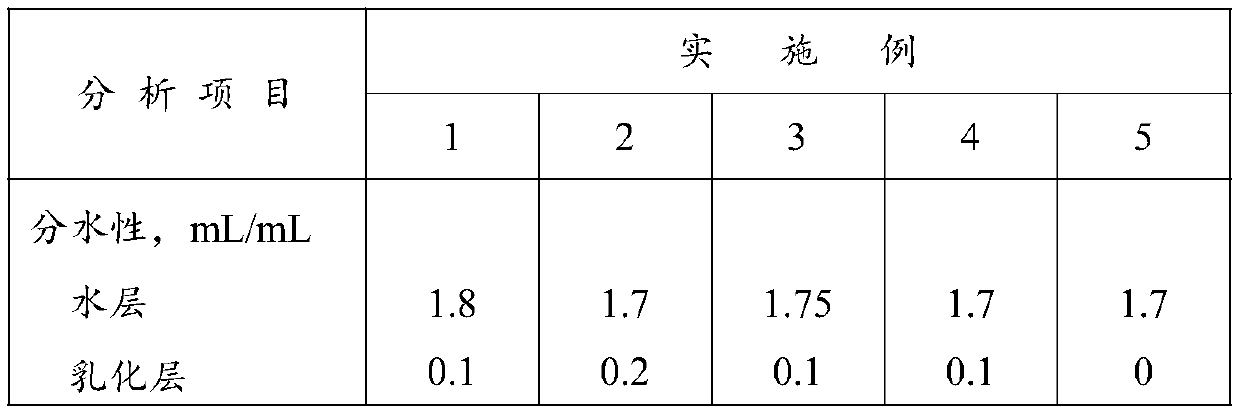

[0027] The present embodiment is calculated in parts by weight, and the composition of each formula is shown in Table 1.

[0028] This embodiment also discloses the preparation method of the aforementioned marine diesel engine oil composition, comprising the following steps:

[0029] High base value syn...

Embodiment 2

[0031] Embodiment 2 discloses a specific embodiment of a marine diesel engine oil composition, in parts by weight, consisting of the following components:

[0032] Detergent: high alkali value synthetic calcium sulfonate T1062 parts, low alkali value petroleum calcium sulfonate T1011.5 parts, high alkali value sulfurized calcium alkylphenate S2062 parts;

[0033] Dispersant: polymer succinimide T1614 parts;

[0034] Antioxidant: phosphodioctyl zinc salt T2031 parts, di-secondary alkyl dithiophosphate zinc salt T2050.5 parts;

[0035] Antifoaming agent: composite antifoaming agent 3# complex anti-0.05 part;

[0036] The base oil is 88.95 parts, and the base oil is specifically mineral oil.

[0037] The present embodiment is calculated in parts by weight, and the composition of each formula is shown in Table 1.

[0038] This embodiment also discloses the preparation method of the aforementioned marine diesel engine oil composition, comprising the following steps:

[0039] Sy...

Embodiment 3

[0041] Embodiment 3 discloses a specific embodiment of a marine diesel engine oil composition, in parts by weight, consisting of the following components:

[0042] Detergent: high alkali value synthetic calcium sulfonate T1062.5 parts, low alkali value petroleum calcium sulfonate T1011 parts, medium alkali value sulfurized alkylphenate calcium T1212.5 parts;

[0043] Dispersant: polymer succinimide T1613 parts;

[0044] Antioxidant: Phosphorus dioctyl zinc salt T2031.5 parts, sulfurized alkylphenol T5040.5 parts;

[0045] Antifoaming agent: composite antifoaming agent 3# complex anti-0.05 part;

[0046] The base oil is 88.95 parts, and the base oil is specifically mineral oil.

[0047] The present embodiment is calculated in parts by weight, and the composition of each formula is shown in Table 1.

[0048] This embodiment also discloses the preparation method of the aforementioned marine diesel engine oil composition, comprising the following steps:

[0049] Synthetic calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com