Device and method for separating oil and water on top of debenzolization tower with excellent separation effect

An oil-water separation device and technology for oil-water separation, applied in separation methods, liquid separation, hydrocarbon purification/separation, etc. Top pressure fluctuations, oil-water separation interface can not be observed and adjusted, etc., to achieve significant economic benefits and safety benefits, improve the effect of oil-water separation, light benzene yield and its quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

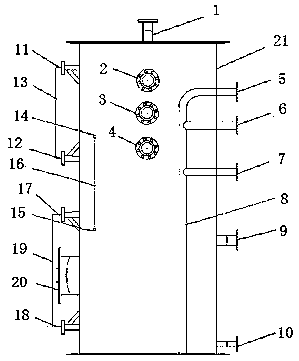

[0033] The oil-water separation device of the present invention consists of a tank body 21, a pressure balance port 1, an oil-water mixture inlet 9, an upper oil return port 2, a middle oil return port 3, a lower oil return port 4, an upper separated water outlet 5, and a middle separated water outlet 6 , lower separated water outlet 7, separated water outlet main pipe 8, vent 10, upper liquid level meter 13, middle liquid level meter 16, lower liquid level meter 19, manhole 20 and form.

[0034]The figure shows that the tank body 21 is an upright steel plate cylinder, and the tank body 21 is made of 8-12mm thick steel plates, 5-12mm thick steel pipes of different diameters and flanges of corresponding diameters. The straight pipe section of the pressure balance port 1 with a flange is vertically fixedly welded to the central opening of the top cover of the tank body 21, and the pressure balance port 1 is connected to the pressure balance port in the debenzene tower through a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com