Fast bright quenching oil and preparation method thereof

A quenching oil and bright technology, which is applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of reducing oil performance, interference, and poor stability of quenching oil, etc., to achieve extended use effect, improve stability, and improve cooling speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

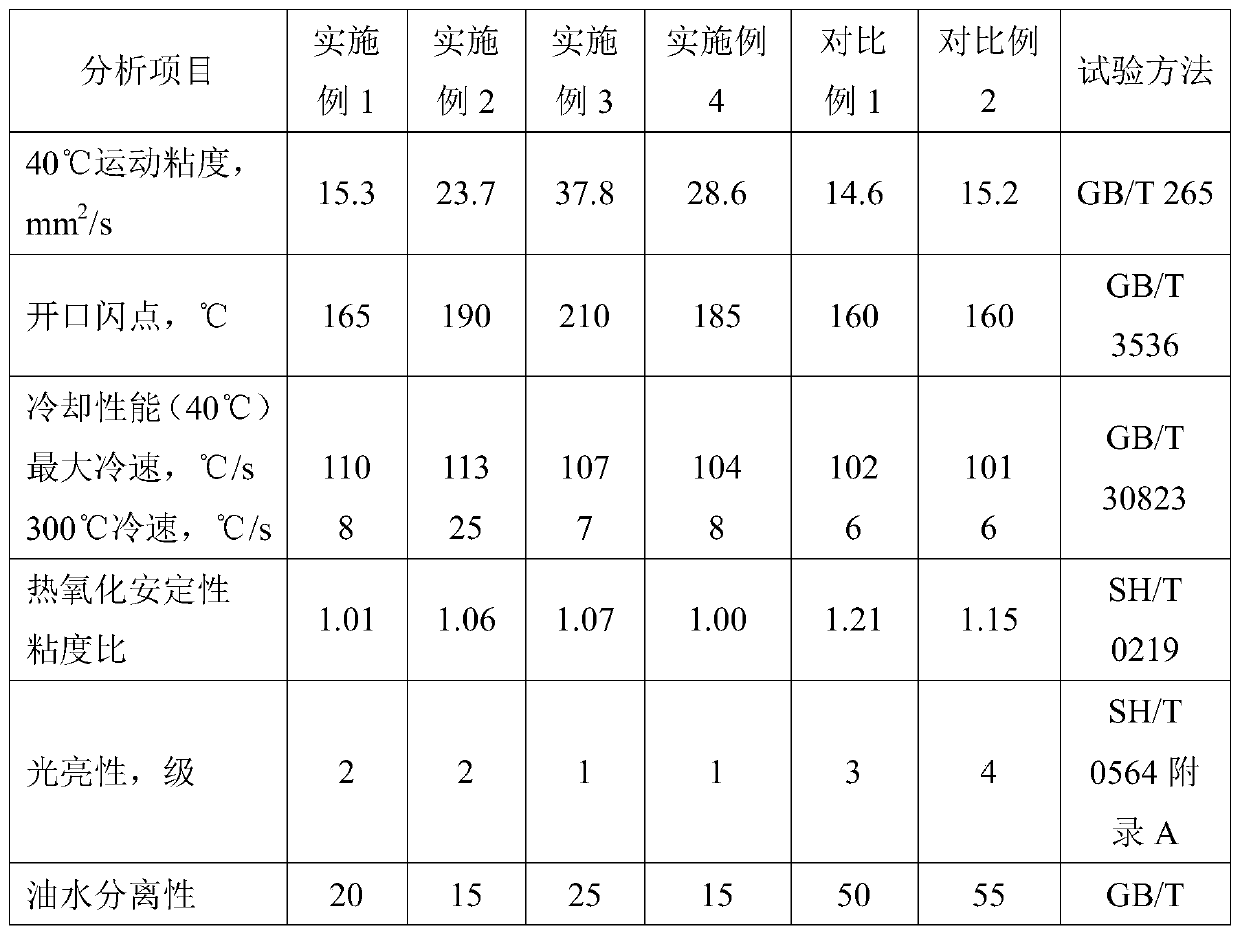

Examples

Embodiment 1

[0029] The quick and bright quenching oil of the present invention is mixed with the following components by weight percentage:

[0030] Refined mineral oil (40℃ kinematic viscosity 10mm 2 / s, saturated hydrocarbon content 92%, cycloalkane content 45%, viscosity index 92) 89%, polyisobutylene (molecular weight 500) 4%, polymethacrylate (molecular weight 5000) 2%, imidazoline oleate 2% , polyisobutylene succinimide (molecular weight 1000, N mass percentage 2%) 1%, 2,6-di-tert-butyl-p-cresol 0.5% and alkyl diphenylamine 1.5%.

[0031] The quenching oil of embodiment 1 is prepared by the following method:

[0032] (1) Add 30% refined mineral oil, polyisobutylene, polymethacrylate, 2,6-dibutyl p-cresol and alkyl diphenylamine to the reaction kettle and mix them in turn, stir well and then add the formula amount of polyisobutylene succinimide, heated up to 70°C, and kept for 3h;

[0033] (2) Add the remaining 59% refined mineral oil to the mixed material in step (1). After cooli...

Embodiment 2

[0035] The quick and bright quenching oil of the present invention is mixed with the following components by weight percentage:

[0036] Refined mineral oil (40℃ kinematic viscosity 20mm 2 / s, saturated hydrocarbon content 95%, cycloalkane content 40%, viscosity index 100) 84%, ethylene-propylene random copolymer (molecular weight 3000) 4%, polymethacrylate (molecular weight 2000) 5%, petroleum sulfonate Salt (molecular weight 1000) 1%, oleic acid amide 5%, polyisobutylene succinimide (molecular weight 2300, N content 1.8%) 0.5%, liquid polymer phenol 0.2% and alkylphenyl-α-naphthylamine 0.3%.

[0037] The quenching oil of embodiment 2 adopts following method to prepare:

[0038] (1) Add 40% refined mineral oil and ethylene-propylene random copolymer, polymethacrylate, petroleum sulfonate, liquid high molecular weight phenol and alkylphenyl-α-naphthylamine to the reaction in sequence Mix in the kettle, stir evenly, add polyisobutylene succinimide in the same amount as the f...

Embodiment 3

[0041] The quick and bright quenching oil of the present invention is mixed by the following components by weight percentage: refined mineral oil (40 ℃ kinematic viscosity 30mm 2 / s, saturated hydrocarbon content 98%, cycloalkane content 40%, viscosity index 110) 92%, dialkyl naphthalene (molecular weight 3000) 1%, polyisobutylene (molecular weight 2000) 3%, imidazoline oleate 1.5%, Polyisobutylene succinimide (molecular weight 2300, N content 1.8%) 2%, thioether phenol 0.2% and octylbutyl dianiline 0.3%.

[0042] The quenching oil of embodiment 3 is prepared by the following method:

[0043](1) Add 35% refined mineral oil, dialkylnaphthalene, petroleum asphalt, thioether phenol and octylbutyl diphenylamine to the reaction kettle and mix them in turn. After stirring evenly, add polyisobutylene butylene For diimide, heat up to 75°C and keep warm for 2.5h;

[0044] (2) Add the remaining 57% refined mineral oil to the mixed material in step (1), after cooling to 40° C., add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com