Improved low-resistance injector

A technology of low-resistance syringes and top caps, applied in the direction of hypodermic injection devices, etc., which can solve problems such as the inability to mass-produce on a large scale, the inability to effectively reduce the frictional resistance between the piston and the barrel wall, and the inability to automatically adjust the sealing degree of the piston and the barrel wall, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

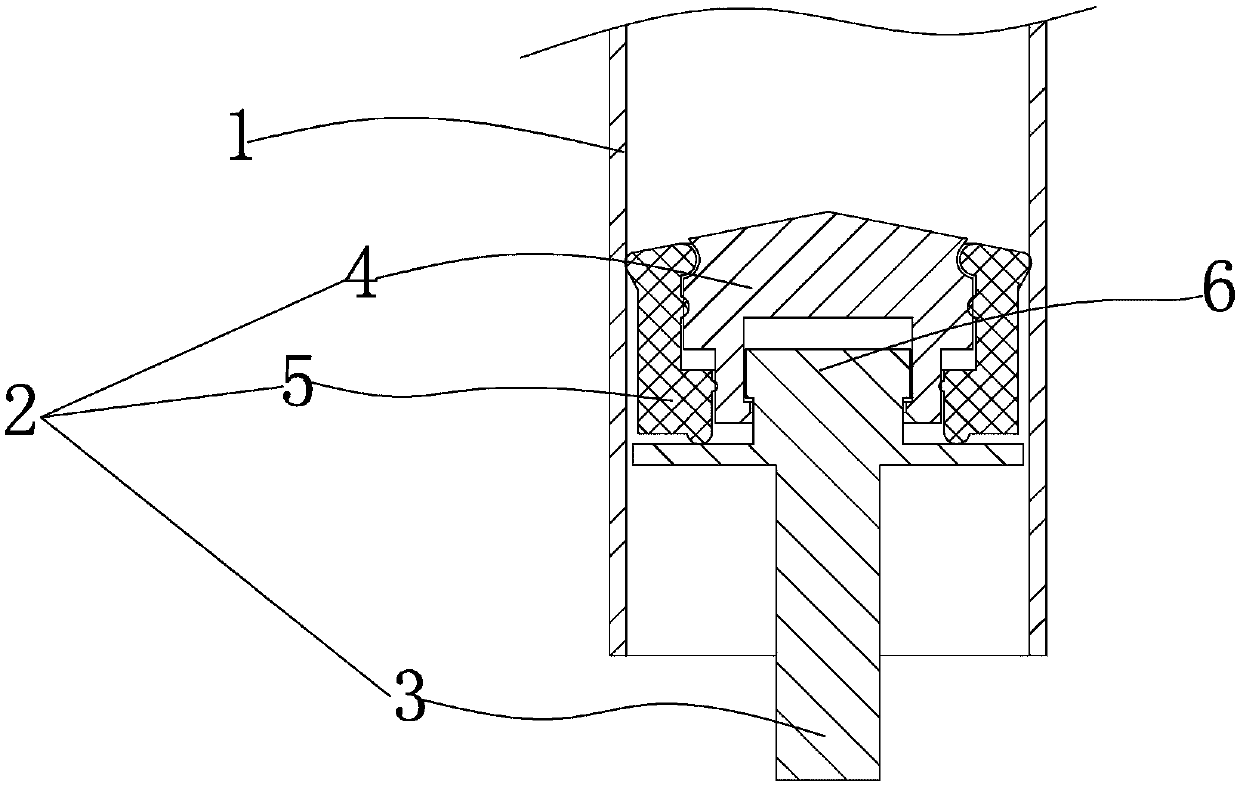

[0019] see figure 1 , an improved low-resistance syringe, comprising a syringe 1, a piston 2, the piston 2 is composed of a push rod 3, a top cap 4, and a rubber plug 5, the top cap 4 is installed on the installation head 6 at the front end of the push rod, and the rubber plug 5 Put it on top cap 4.

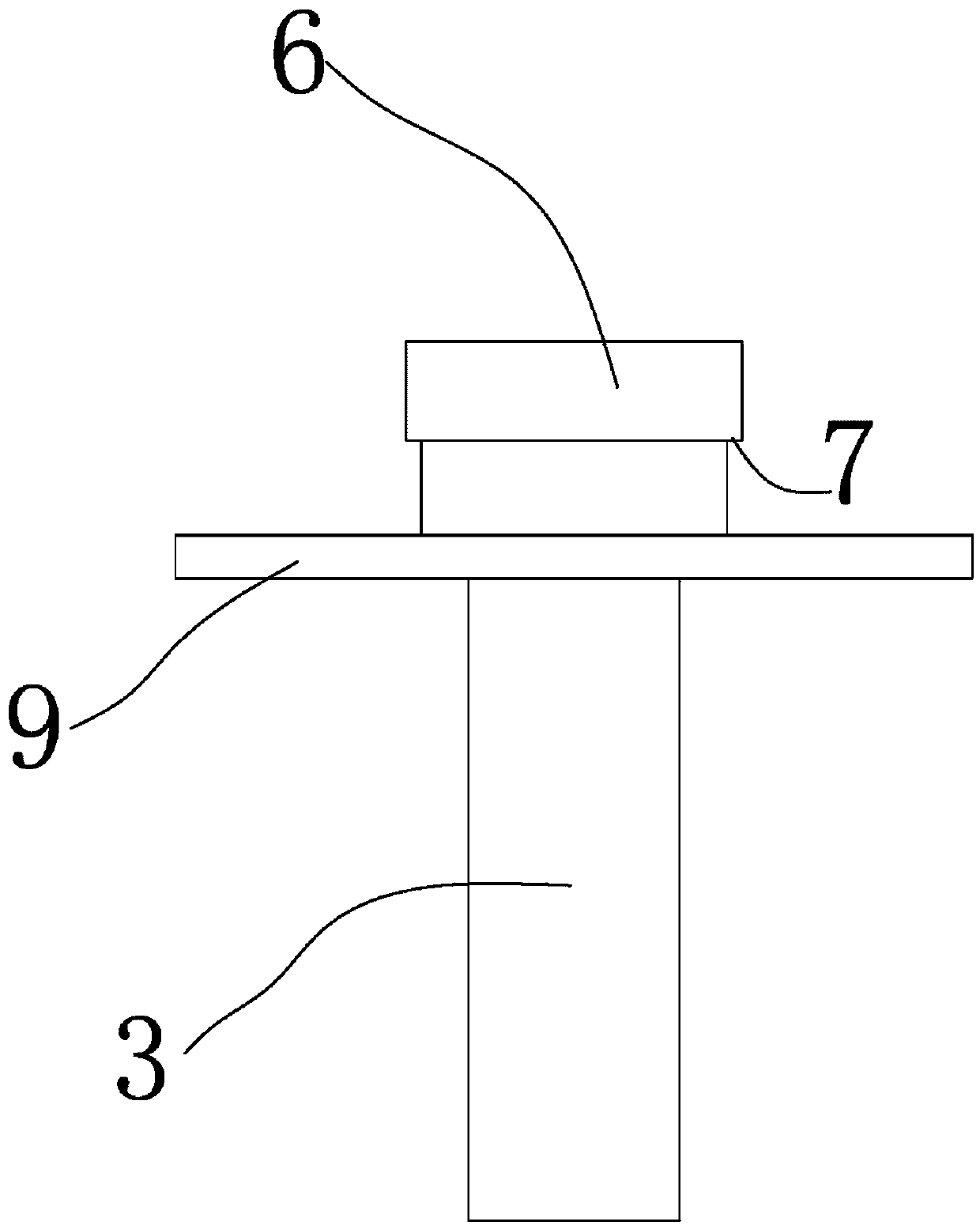

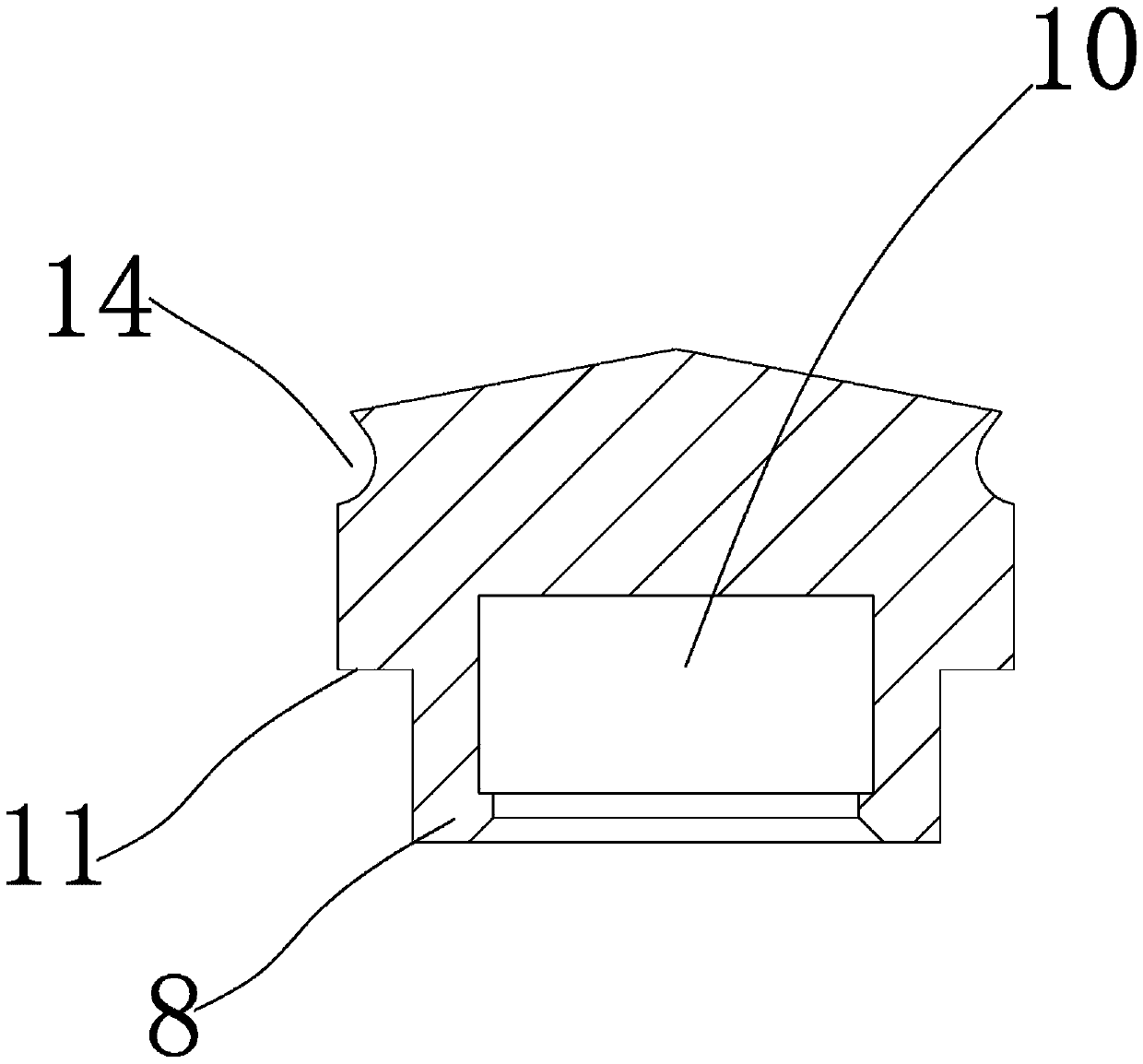

[0020] see figure 2 , image 3 , Figure 4 , The mounting head 6 of the push rod is provided with a shoulder 7, and correspondingly, the lower part of the top cap 4 is provided with a clamping foot 8 matched with the shoulder 7. The cooperation between the shoulder 7 and the clamping foot 8 can make the top cap 4 and the push rod 3 lock each other firmly without slipping off. The position where the push rod is located below the rubber plug is formed with a push plate 9, which can easily push the rubber plug 5. The top cap 4 is provided with an inner cavity 10 for placing the push rod installation head 6. In the initial state, there is a gap between the top of the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com