Continuous method for preparing high dispersion nano oxide powder by jet coprecipitation

A nano-oxide, high-dispersion technology, applied in the production field of nano-powder preparation, can solve problems such as uneven distribution of metal ions and precursors, difficulty in measuring the pH value of the reaction solution, uneven distribution of precursors, etc., to achieve cost Low, high yield, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

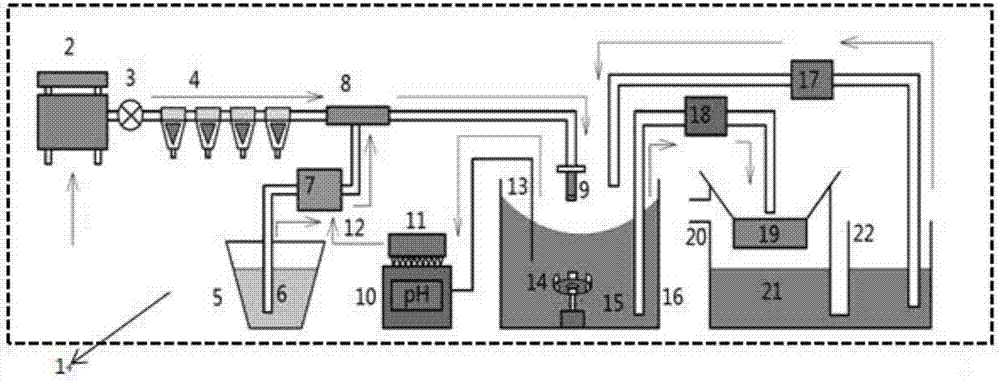

[0021] Example 1: Y 2 o 3 Transparent ceramic powder

[0022] Preparation concentration is the yttrium nitrate solution of 3.0mol / L, is contained in container two (16), and preparation concentration is the ammonium bicarbonate of 1.5mol / L and ammoniacal liquor as precipitation agent solution (6), the mole of ammonium bicarbonate and ammoniacal liquor The concentration ratio is 1:2, and it is contained in container one (5). The experimenter turns on the air compressor (2), the pressure of the air compressor is 300KPa, the air compressor (2) works, the air enters the continuous device (1), and the air flows into the pressure relief valve (3) from the conduit, and the pressure relief valve (3) will The pressure is adjusted to an appropriate size, and the air flows into the four-stage filter (4) and the T-type transfer valve (8), wherein the filter (4) filters out impurities in the air. Pump one (7) inhales the precipitating agent (6) (ammonium bicarbonate and ammoniacal liquor...

Embodiment 2

[0025] Embodiment 2: YAG transparent ceramic powder

[0026] Prepare an aluminum nitrate solution in the ratio of n(Al):n(Y)=5:3, the concentration is 1.0mol / L, put it in the container two (16), configure the ammonium bicarbonate solution as the precipitating agent (6), carbonic acid The concentration of ammonium hydrogen is 1.92mol / L, which is contained in container one (5); the experimenter turns on the air compressor (2), the pressure of the air compressor is 100KPa, the air compressor (2) works, and the air enters the continuous device (1), The air flows into the pressure reducing valve (3) from the conduit, the pressure reducing valve (3) adjusts the pressure to an appropriate size, and the air flows into the fourth-stage filter (4) and the T-type transfer valve (8), wherein the filter (4) Filter out impurities in the air. Pump one (7) sucks the precipitating agent (6) in container one (5) at a rate of 10ml / min, and the precipitating agent (6) flows through the T-shaped ...

Embodiment 3

[0029] Embodiment 3: Al2O3 transparent ceramic powder

[0030] The experimenter prepares an aluminum nitrate solution with a concentration of 0.1mol / L, and puts it in a container two (16), and prepares an ammonium bicarbonate solution with a concentration of 1.5mol / L as a precipitant solution (6), and puts it in a container one (5). Inside. The experimenter turns on the air compressor (2), the pressure of the air compressor is 500KPa, the air compressor (2) works, the air enters the continuous device (1), and the air flows into the pressure relief valve (3) from the conduit, and the pressure relief valve (3) will The pressure is adjusted to an appropriate size, and the air flows into the four-stage filter (4) and the T-type transfer valve (8), wherein the filter (4) filters out impurities in the air. Pump one (7) inhales the precipitant (6) (ammonium bicarbonate solution) in container one (5) at a rate of 20ml / min, and the precipitant (6) flows through the T-type transfer val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com