Preparation method and application of high-performance calcium-based heat carrier

A high-performance, calcium-based technology, applied in the field of energy storage materials, can solve the problem of difficulty in improving the uniformity of the calcium-based heat carrier, and achieve the effects of superior cycle energy storage characteristics, high energy storage activity, and improved tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

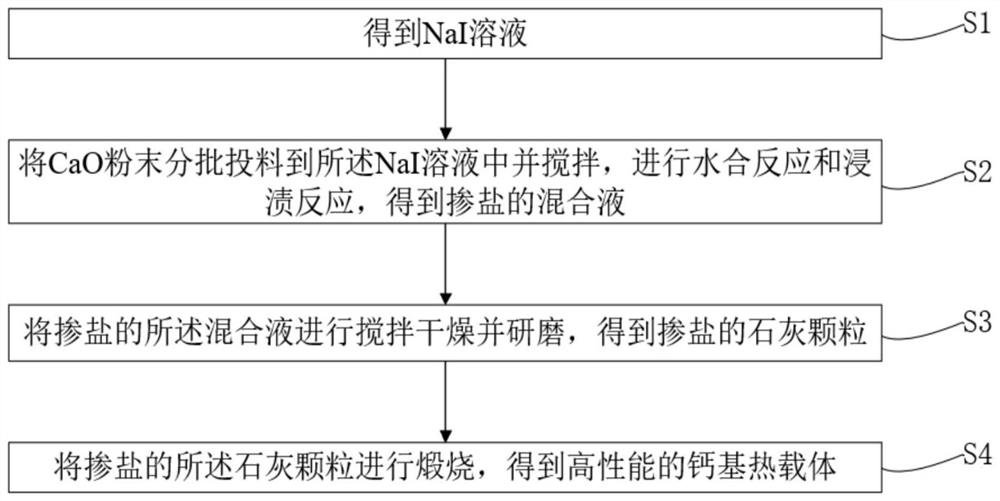

[0042] In an embodiment of the present application, as figure 1 As shown, a kind of preparation method of high-performance calcium-based heat carrier is provided, and described method comprises:

[0043] S1. obtain NaI solution;

[0044]S2. the CaO powder is fed into the described NaI solution in batches and stirs, carries out hydration reaction and dipping reaction, obtains the mixed solution of doped salt;

[0045] S3. the mixed solution mixed with salt is stirred, dried and ground to obtain the lime particles mixed with salt;

[0046] S4. calcining the lime particles mixed with salt to obtain a high-performance calcium-based heat carrier;

[0047] The molar ratio of NaI and CaO in the mixed solution is 1-5:90-105.

[0048] In this application, the positive effect that the molar ratio of NaI and CaO in the mixed solution is 1-5:90-105 is that NaI is a sodium salt with a low melting point, which is easy to promote the high-temperature sintering of CaO, and can also promote...

Embodiment 1

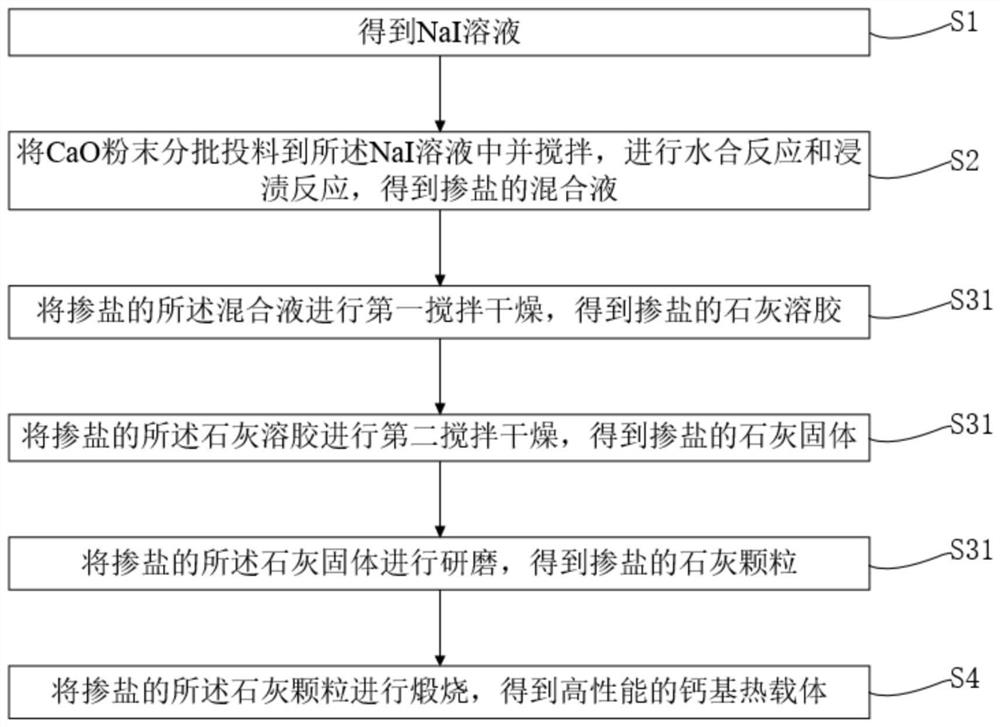

[0078] like figure 1 Shown, a kind of preparation method of high-performance calcium-based heat carrier, described method comprises:

[0079] S1. Obtain NaI solution;

[0080] S2. Feed the CaO powder in batches into the NaI solution and stir, carry out hydration reaction and impregnation reaction, and obtain the mixed solution mixed with salt;

[0081] S31. Perform the first stirring and drying of the mixed solution mixed with salt to obtain a lime sol mixed with salt;

[0082] S32. Carrying out the second stirring and drying of the lime sol mixed with salt to obtain the lime solid mixed with salt;

[0083] S33. Grinding the lime solids mixed with salt to obtain lime particles mixed with salt;

[0084] S4. Calcining the salt-doped lime particles to obtain a modified calcium-based heat carrier.

[0085] The molar ratio of NaI and CaO in the mixed solution is 2:100.

[0086] The mass concentration of NaI solution is 2%.

[0087] The temperature of the first stirring and dr...

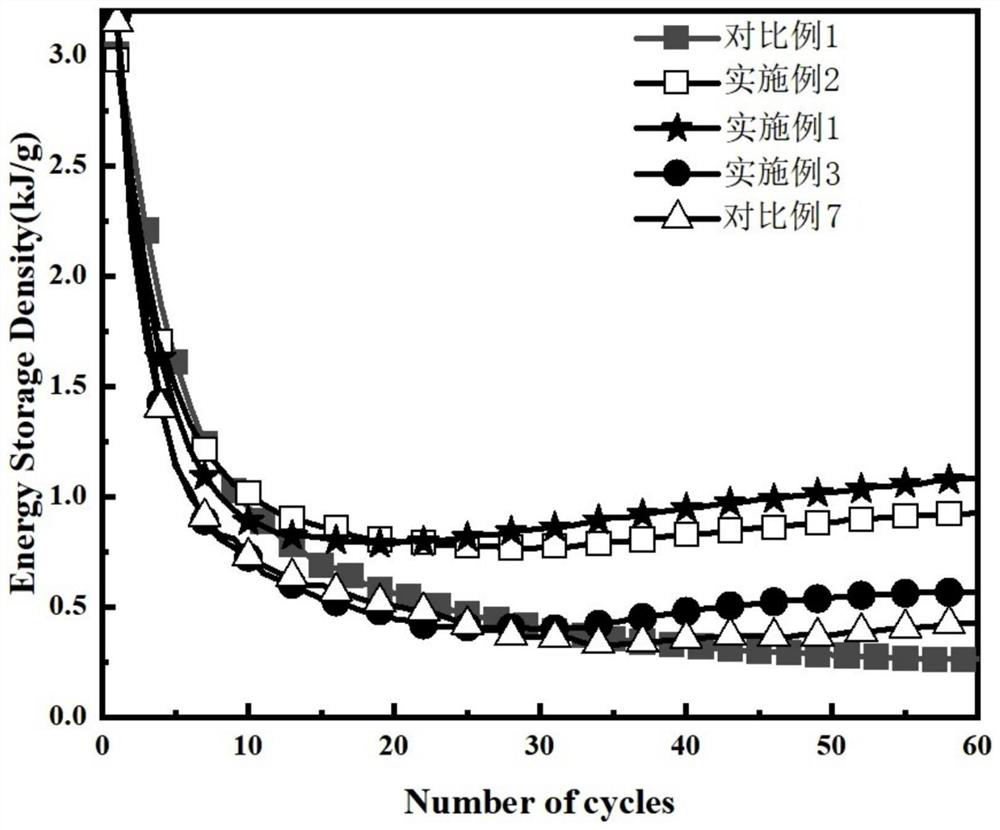

Embodiment 2

[0098] Compare embodiment 2 and embodiment 1, the difference of embodiment 2 and embodiment 1 is:

[0099] The molar ratio of NaI and CaO in the mixed solution is 1:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com