Patents

Literature

45results about How to "High resistance to laser damage threshold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

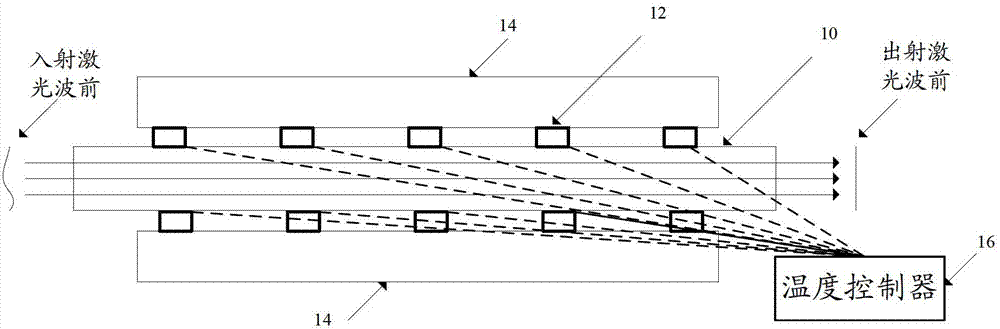

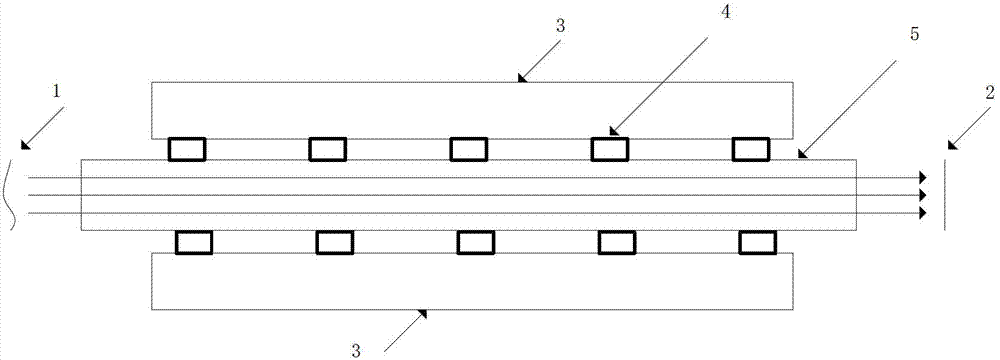

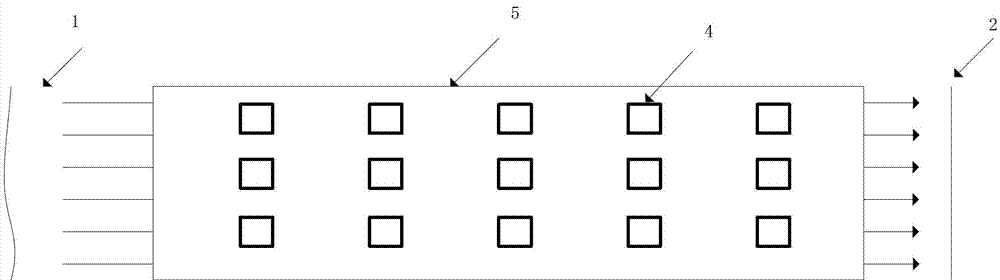

Optical device for laser beam wave-front correction and wave-front correction method

InactiveCN102957085AIncrease the lengthExtended propagation distanceLaser detailsTemperature controlLight beam

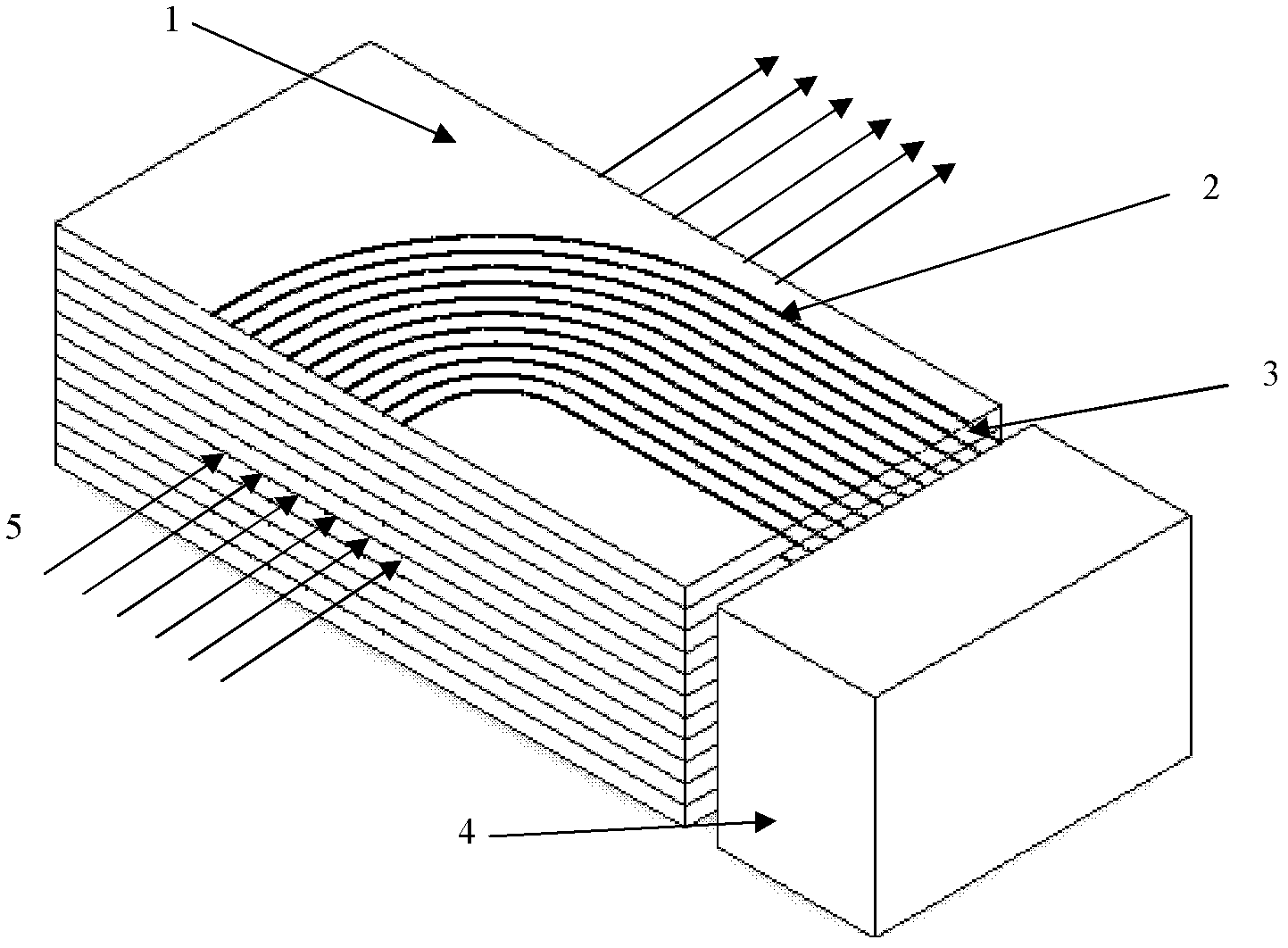

The invention discloses an optical device for laser beam wave-front correction and a laser beam wave-front correction method. The optical device comprises an optical material, temperature controlling units, a radiating device and a temperature controller, wherein the optical material is used for receiving laser beams emitted from a laser gain medium through one end face, and emitting laser beams from another end face or emitting from the end face for receiving laser beams; theeach temperature control unit is used for heating or cooling under the control of the temperature controller; the radiating device is used for dissipating waste heat generated by the temperature control unit(s) when the temperature controller is used for controlling the temperature control unit(s) to cool; and the temperature controller is used for controlling the one or more temperature control units to heat or cool and controlling the heating amount or cooling amount of the one or more temperature control units, so as to control the temperature of laser beams on a path in the optical material and correct the wave-front of laser beams emitted into the optical material.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

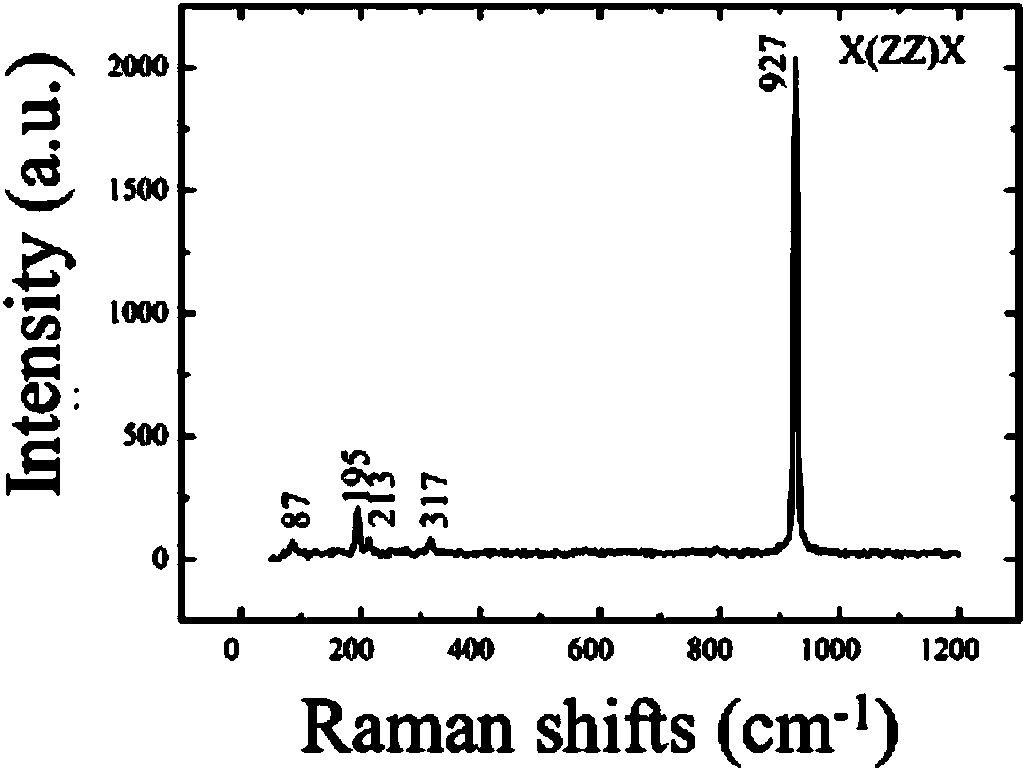

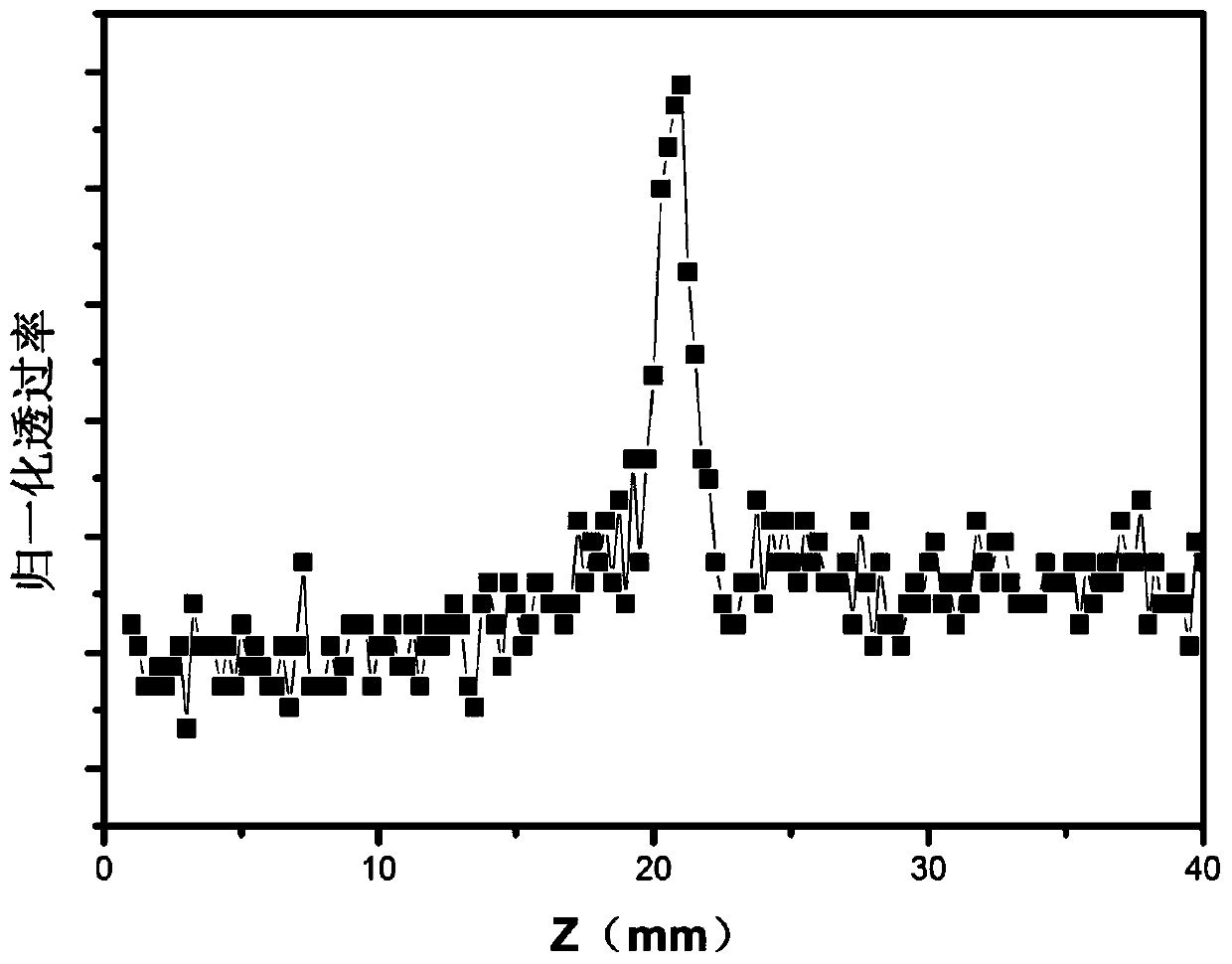

Application of Ca3(BO3)2 crystal stimulated Raman scattering

ActiveCN104348081AEasy to manufactureNo pollution in the processLaser using scattering effectsActive medium materialUltravioletStimulate raman scattering

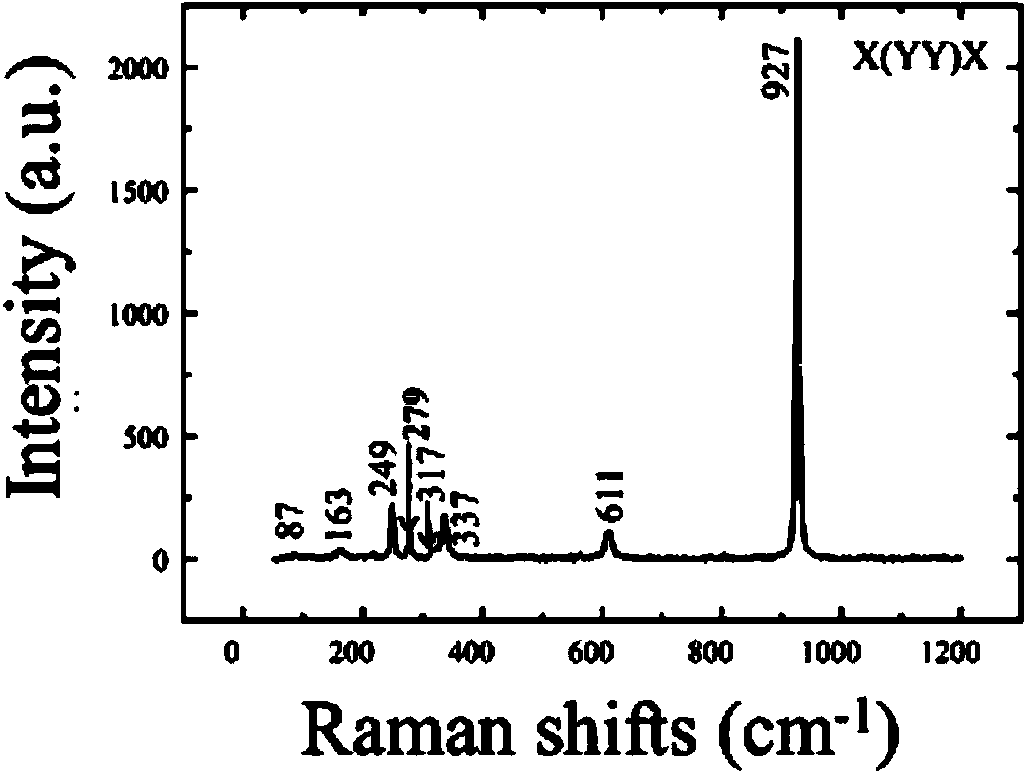

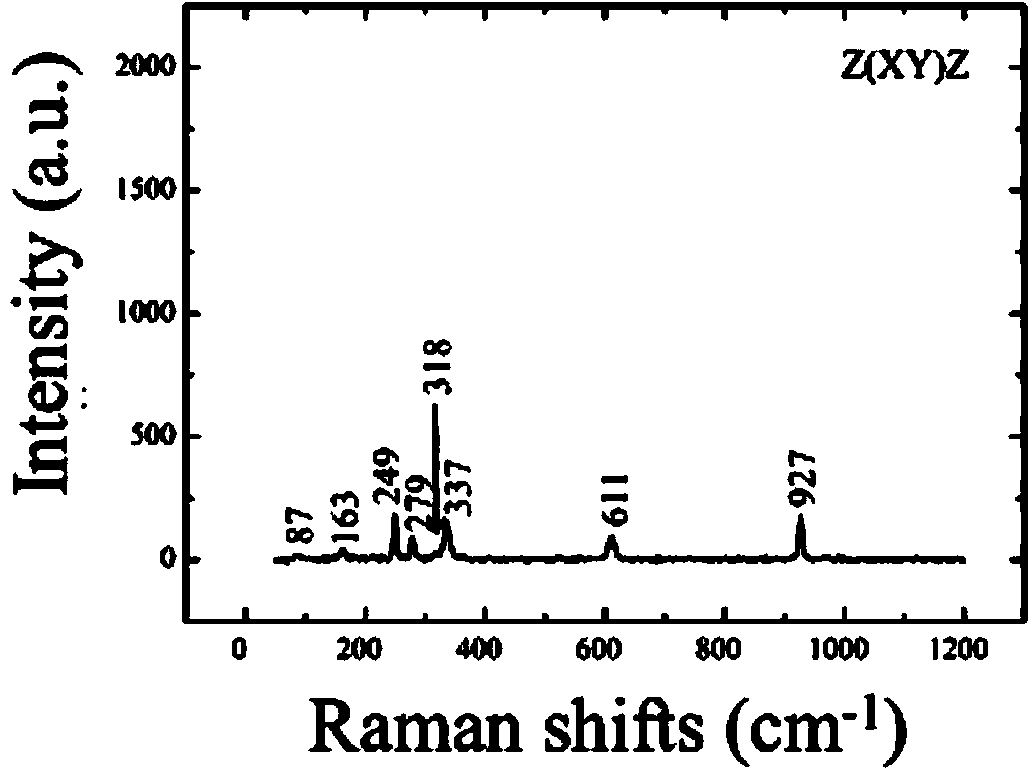

The invention provides application of Ca3(BO3)2 crystal stimulated Raman scattering. A Ca3(BO3)2 crystal is machined into a Raman device along an optical main axis (90 degrees, 0 degree), namely, an X axis; laser light of high-peak power is emitted along the X axis; Raman scattering laser light is obtained by using maximum Raman shift, a high optical damage resisting threshold value and a high Raman gain. The Ca3(BO3)2 Raman crystal is machined into a stimulated Raman scattering device by using the characteristics of easiness in manufacturing, prevention of pollution, low manufacturing cost, high optical damage resisting threshold value, short ultraviolet stop edge, high transmittance, large Raman shift and the like, so that the size of a Raman laser is reduced, the performance of the Raman laser is enhanced, and the application of a deep ultraviolet Raman laser is facilitated.

Owner:SHANDONG UNIV

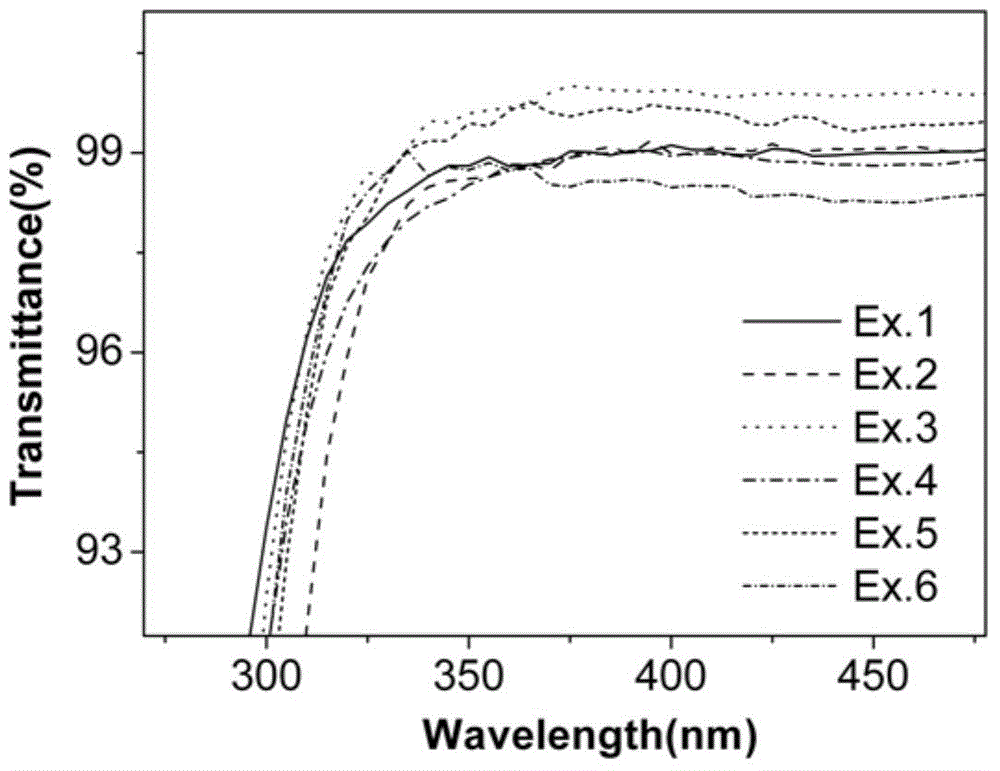

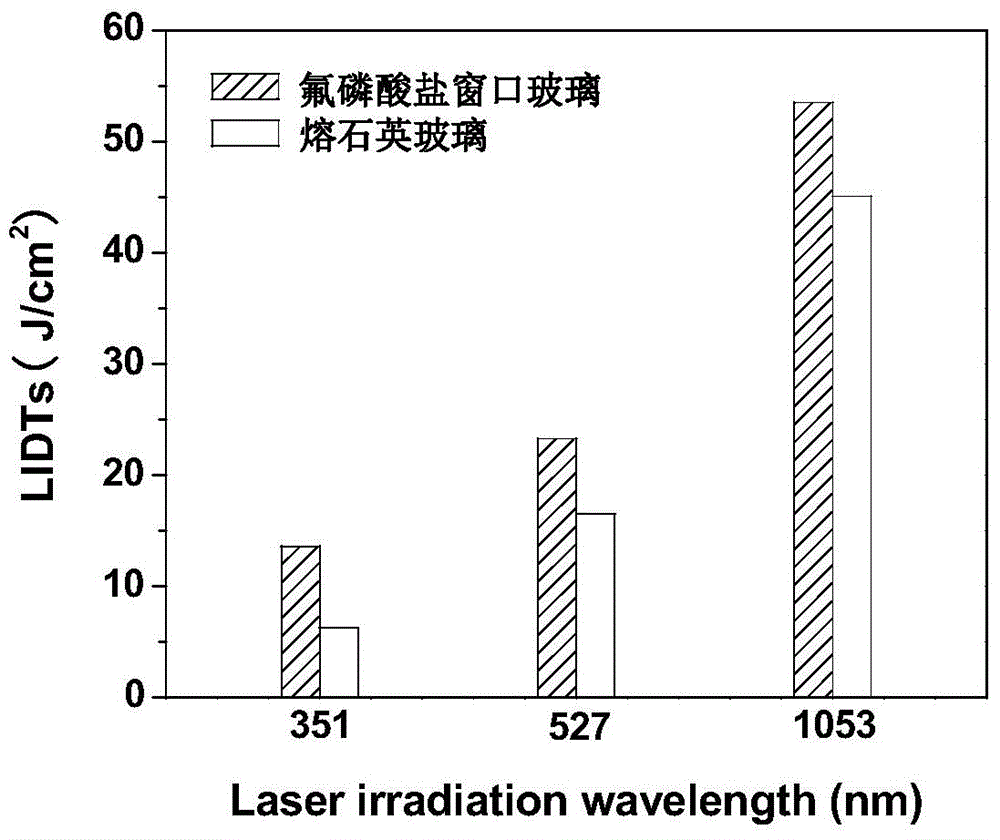

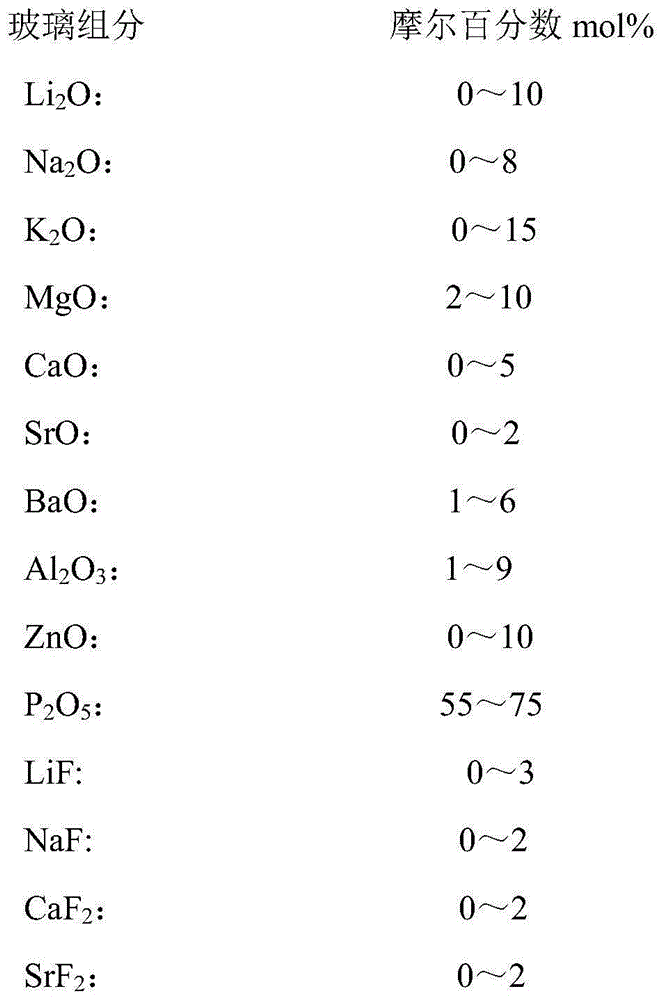

Ultraviolet-transmittance and high-damage-threshold fluoride phosphate laser glass and preparation method thereof

ActiveCN105000801AGood spectral transmission performanceHigh resistance to laser damage thresholdGlass furnace apparatusGlass shaping apparatusHigh power lasersHigh energy

The invention provides high-damage-threshold fluoride phosphate laser glass as a material for preparing an ultraviolet-transmittance window, and a preparation method of the high-damage-threshold fluoride phosphate laser glass. The preparation method comprises the steps of adopting an alkali metal oxide, an alkaline earth metal oxide, alumina, zinc oxide and phosphoric pentoxide as main raw materials, adding a small amount of rare earth fluoride, molding and preparing glass pressing blanks based on the drip injection method after the treatments of high-temperature melting, clarification and homogenizing, and finally obtaining the high-damage-threshold fluoride phosphate laser glass material through the annealing treatment. The fused quartz material can be replaced by the above glass material for preparing lenses, plane windows, prisms and other optical components applied to high-energy and high-power laser systems. In this way, the laser-induced damage problems of ultraviolet optical components made of the fused quartz material in existing high-energy and high-power laser systems can be solved. The load output capability of a laser is further improved. Therefore, the above material can be used for preparing the ultraviolet-transmittance optical components of high-power lasers for laser-driven inertial confinement fusion experiments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

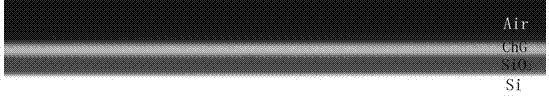

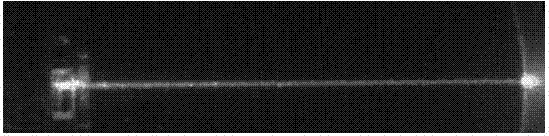

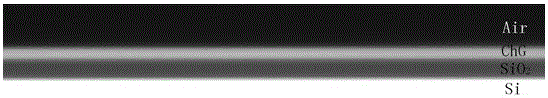

Photoinduced stable nonlinear sulfur film, and preparation method thereof

InactiveCN103572218AHigh resistance to laser damage thresholdGood optical performanceSelenium/tellurium compundsVacuum evaporation coatingChemistryBand gap

The invention discloses a photoinduced stable nonlinear sulfur film, and a preparation method thereof, and belongs to an optical film and a nonlinear optical material. The chemical composition of the film is GexAsySzSe(100-x-y-z), wherein x is smaller than or equal to 14 and greater than or equal to 10; y is smaller than or equal to 28 and greater than or equal to 20; z is smaller than or equal to 50 and greater than or equal to 16. A vacuum thermal evaporation method is adopted in preparation of the film; the vacuum degree is 10<-4> to 10<-6> torr; the evaporation rate is 3-20 nm / min; the refractive index of the sulfur film prepared by the method at wavelength of 1.55 microns is 2.20-2.56; the refractive index change of the film under thermal annealing and sub-band gap illumination is 10<-3>; an optical band gap is 1.98-2.48ev; the loss of the film at the wavelength of 1.55 microns is smaller than 0.2 dB / cm; the third-order nonlinear refractive index at the wavelength of 1.55 microns is 2.0-6.0*10<-14> cm<2> / W; no significant two-photon is absorbed; a laser-damaged threshold is greater than 200 GW / cm<2> (5.3 microns, 150fs, 1kHz). The photoinduced stable nonlinear sulfur film has the advantages that 1, the photoinduced refractive index change is tiny, and the optical performance of an apparatus is stable; 2, the anti-laser damage threshold of the film is high, and application of the apparatus in the field of nonlinear optics is facilitated; 3, the composition and the refractive index of the film obtained by vacuum evaporation are consistent with those of adopted block raw materials, and the films produced in different batches are consistent in performance, and easy to control.

Owner:XUZHOU NORMAL UNIVERSITY

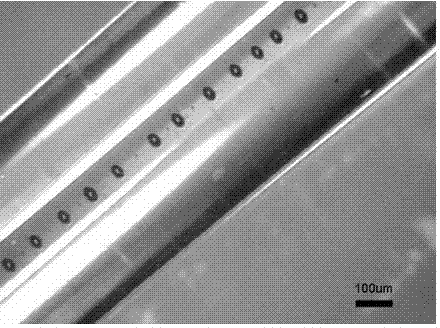

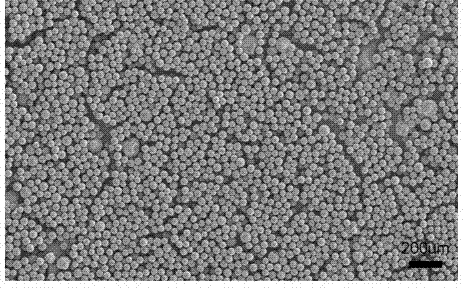

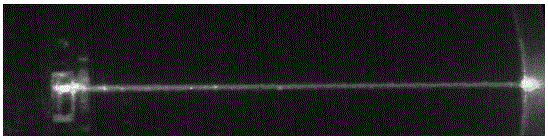

High-performance chalcogenide glass microsphere and preparation method thereof

ActiveCN103613276AGood spherical shapeLight-induced refractive index change is smallGlass shaping apparatusMicrosphereRefractive index

The invention discloses a high-performance chalcogenide glass microsphere and a preparation method thereof, wherein the glass microsphere belongs to an optical microsphere and an infrared sensing material. The chemical composition of the glass microsphere is GexAsyS100-x-y, wherein x is greater than or equal to 8 and smaller than or equal to 12, while y is greater than or equal to 20 and smaller than or equal to 32. The glass microsphere is obtained by means of heat treating 'chalcogenide glass / polymer' composite optical fibers, and the composite optical fibers are obtained by means of drawing 'chalcogenide glass / polymer' preform rods on an optical fiber drawing tower. The chalcogenide glass microsphere prepared by the method has a diameter of 8-300 micrometers, an eccentricity degree smaller than or equal to 1%, surface smoothness smaller than or equal to 1nm, a microcavity quality factor Q greater than or equal to 1x10<5> and a laser induced damage threshold greater than or equal to 400GW / cm<2>(5.3micrometers, 150fs and 1kHz). The chalcogenide glass microsphere can be applied to the fields of molecular sensing and infrared optics. The chalcogenide glass microsphere and the preparation method have the following advantages that 1. the photon-induced refractive index change of glass is extremely small and the optical stability is good; 2. the laser induced damage resisting threshold of the glass microsphere is relatively high and the glass microsphere serving as an optical microcavity is capable of transmitting relatively high laser power; 3. the preparation technology is simple, the cost is very low and a large number of high-quality microspheres with uniform size can be prepared at a time.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD

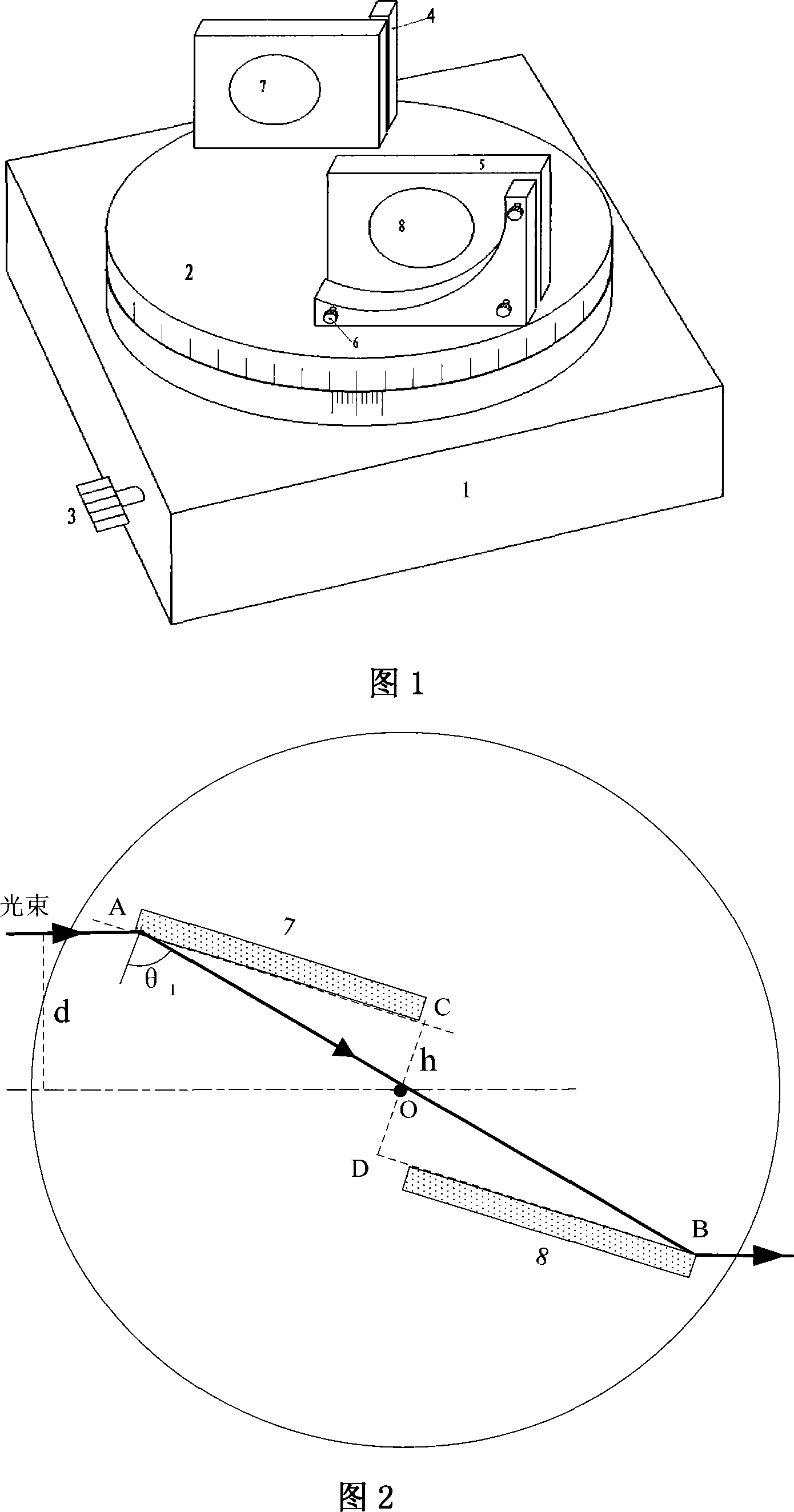

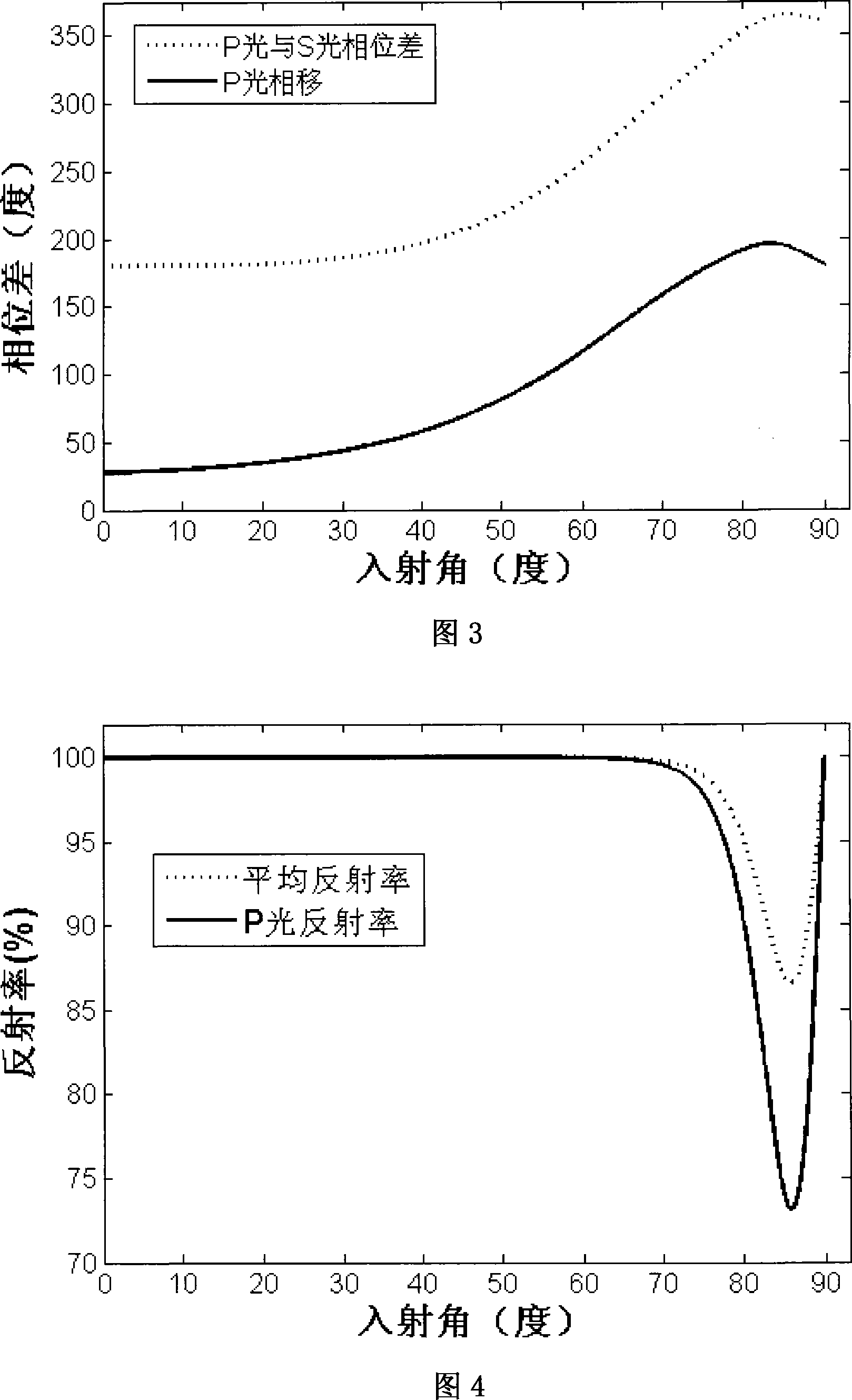

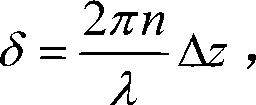

Thin film -type adjustable phase retarder

InactiveCN101236306AThe principle is simpleEasy to manufacturePolarising elementsMountingsPhase retardationLight beam

The invention provides a thin-film type adjustable phase retarder which consists of two thin-film type phase delay plates, two three-dimensional optical adjusting mounts and a precise rotating platform. Two phase delay plates are arranged on the rotating platform and ensure that reflecting surfaces are parallel; a beam of light enters to the first phase delay plate at a certain angle, reflects to the second phase delay plate and emerges parallel to the incident light direction through the second reflection. The rotating platform rotates to change an incidence angle of the beam of light; the phase delay or compensation dosage is also changed along the change of the incident angle, thereby realizing precise and tunable phase delay. The thin-film type adjustable phase retarder is characterized in simple structure, easy manufacturing, high degree of precision, simple operation, multi-purpose, etc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

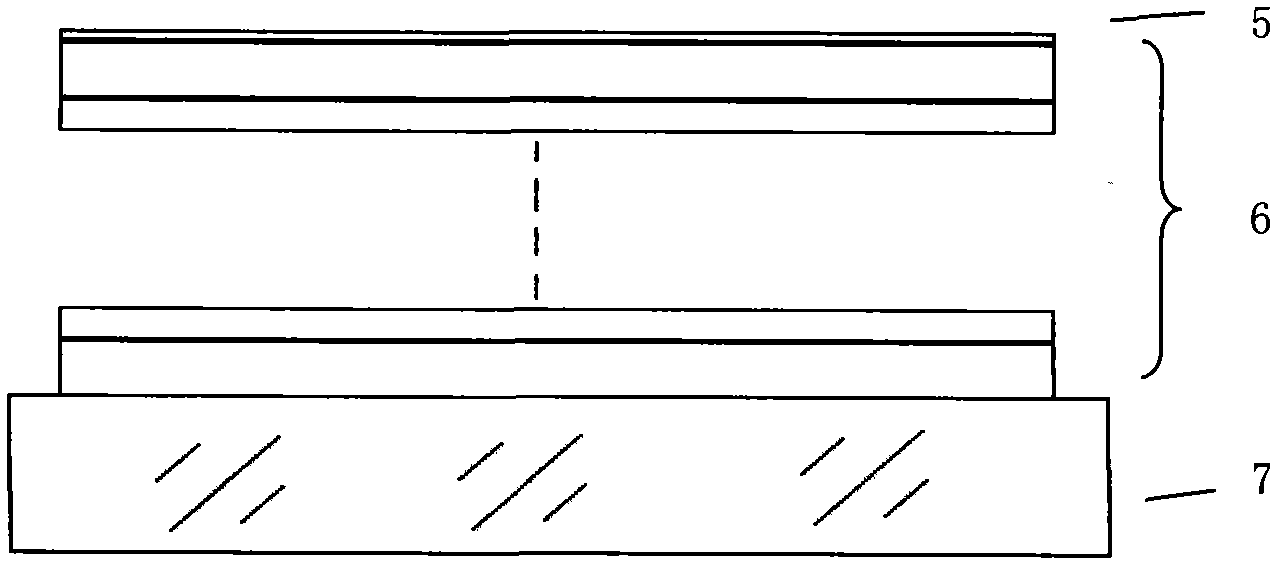

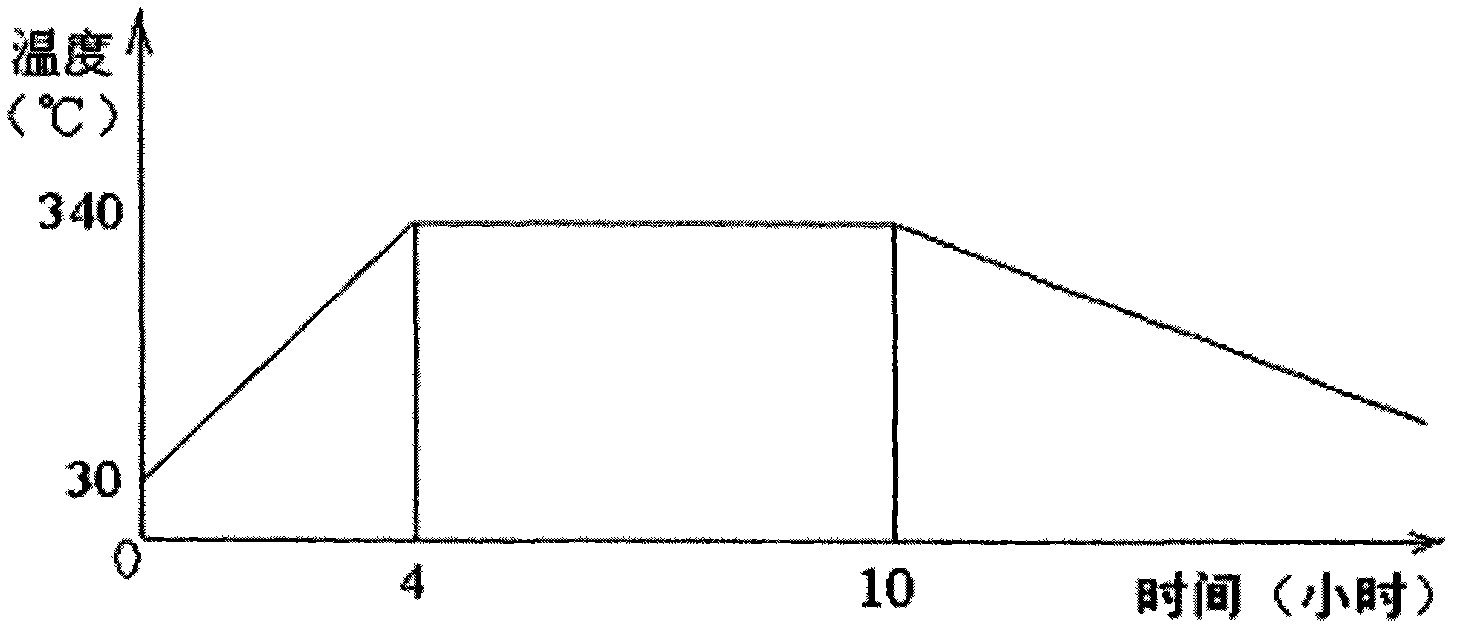

Reflecting mirror with low loss and high reliability

The invention relates to a reflecting mirror with high reliability for a laser gyro prepared through ion beam sputtering. The reflecting mirror is prepared by the following steps of: alternately plating a regularTiO2 / SiO2 film high reflective coating with 1 / 4 working wavelength on a nano-grade quartz base by adopting a double-ion-beam sputtering and depositing process, plating a layer of extremely thin air interface layer material HfO2 at the outermost layer, and carrying out postprocessing under the condition of 340 DEG C / 6h on a reflecting mirror film in the air after the plating is finished. The reflecting mirror provided by the invention has extremely low loss and dispersion, a high laser damage resistant threshold, heat stability within 340 DEG C and favorable plasma discharging environment resisting capacity and can keep stable optical property of over 15000Sec in an environment with the plasma energy of 200w. The reflecting mirror prepared by using the technology provided by the invention has stable working property in a gyro resonator, has high environment reliability and can meet the application requirement of a high-precision laser gyro.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Method for washing optical substrate before film coating

InactiveCN103721969AGood optical performanceHigh resistance to laser damage thresholdCleaning using liquidsChemistryFilm coating

The invention relates to a method for washing an optical substrate before film coating. According to the operating method, diethyl ether and ethyl alcohol are replaced by n-heptane which is used for preparing a mixed washing solution according to a certain proportion, and the mixed washing solution is dripped to optical washing dust-free cloth to wipe and wash optical quartz glass. The dirt removing situation of the substrate is observed through the irradiation of a high-light optical detecting lamp, and accordingly the purpose of cleaning the substrate is achieved. By means of the method for washing the optical substrate before film coating, the adhesive force of an optical thin film can be improved, the anti-laser-damaged threshold value of the thin film can be increased, and the service life of the optical thin film can be prolonged.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

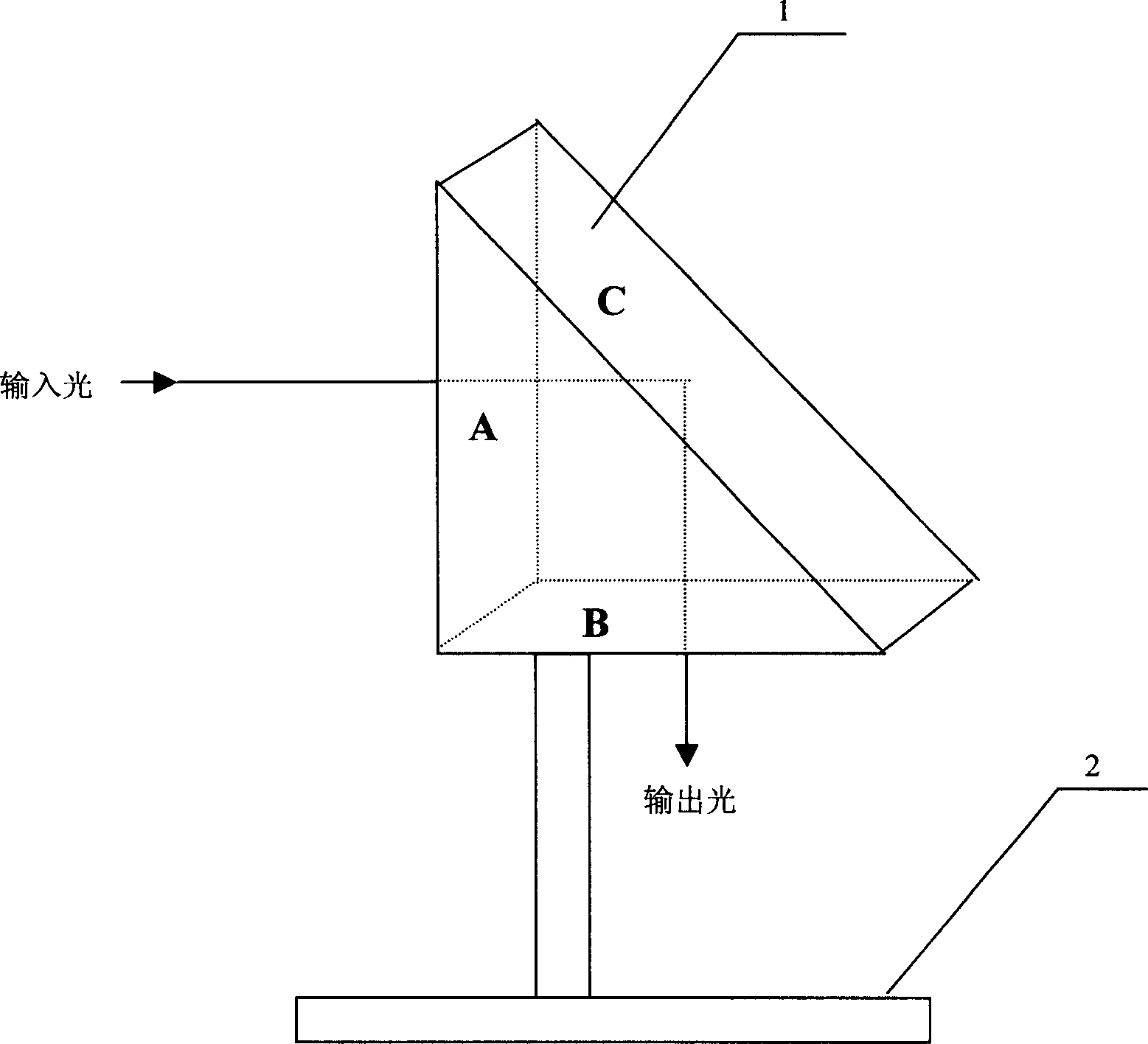

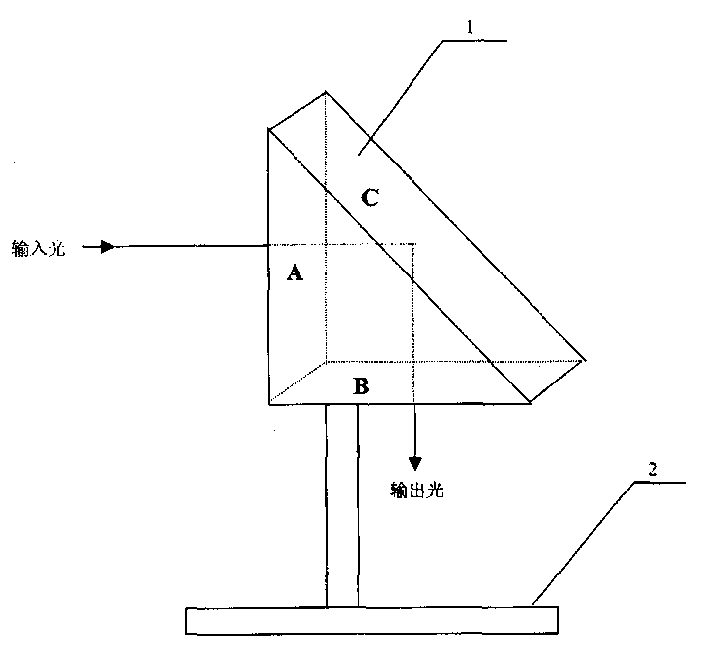

High-reflectivity high-damage threshold superwide-band fs laser reflector

The present invention discloses a high-reflectivity high-damage threshold superwide-band fs laser reflector. On some support or pedestal, there is one rectangular prism with one inclined plane and two right angle planes in the angle of 45 deg to the inclined plane, the inclined plane is optical polished plane and the two right angle planes has anti-reflecting film formed via vacuum vaporizing and coating. Owing to the material and structure, the rectangular prism can transmit fs laser of 200 nm over spectral bandwidth with the transmittance being reaching to 99.5%. The present invention has reasonable design, simple structure, high transmittance, less laser absorption, high laser damage threshold and other advantages. The present invention may be used in various fs laser equipment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

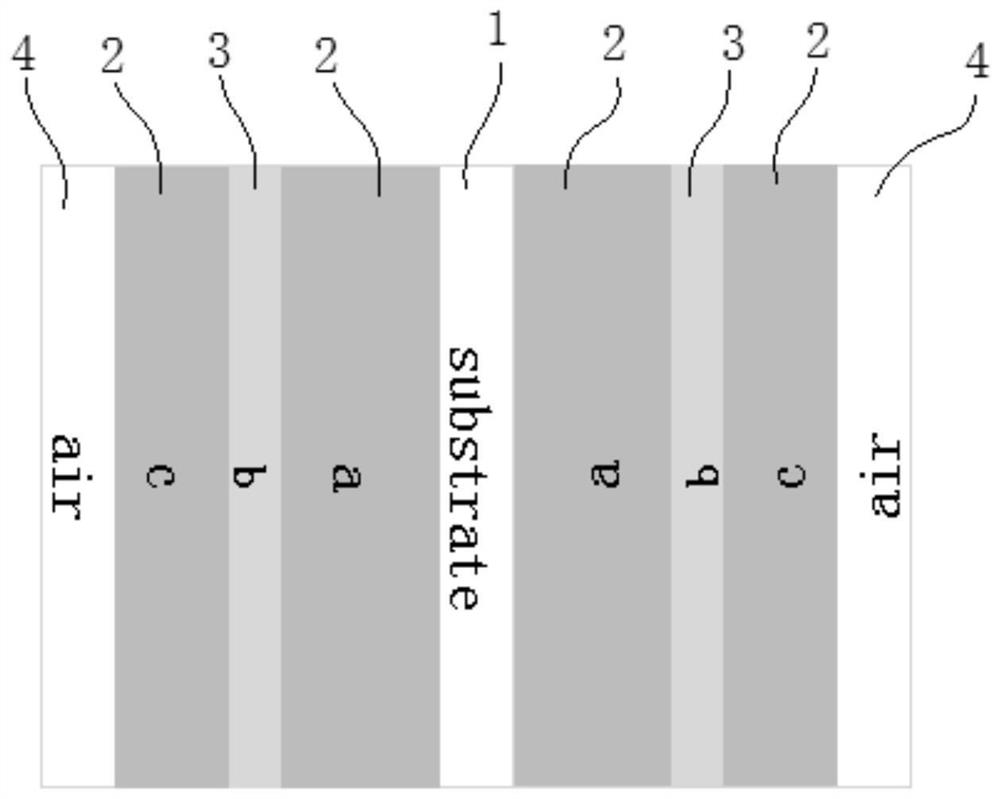

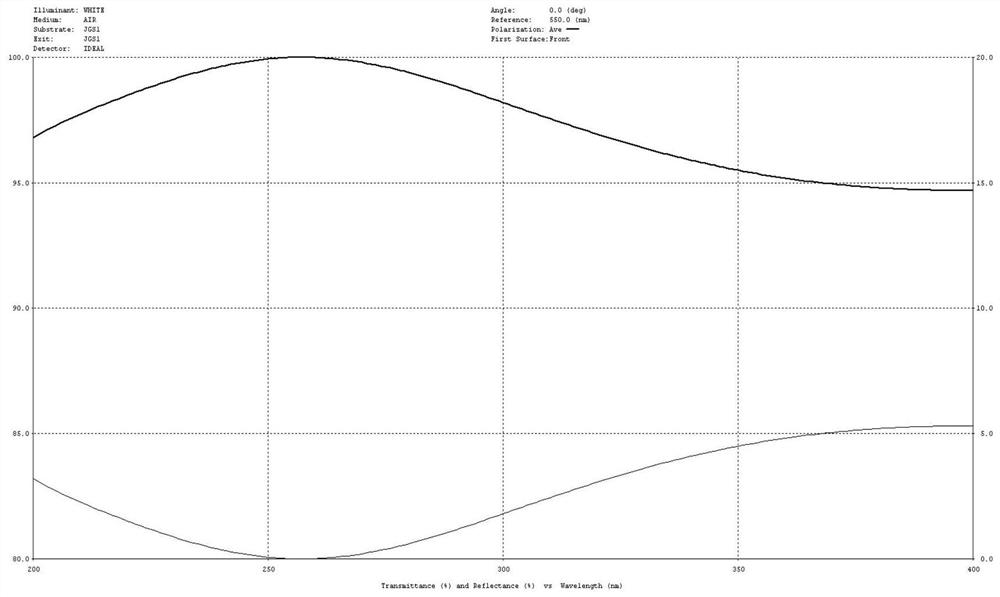

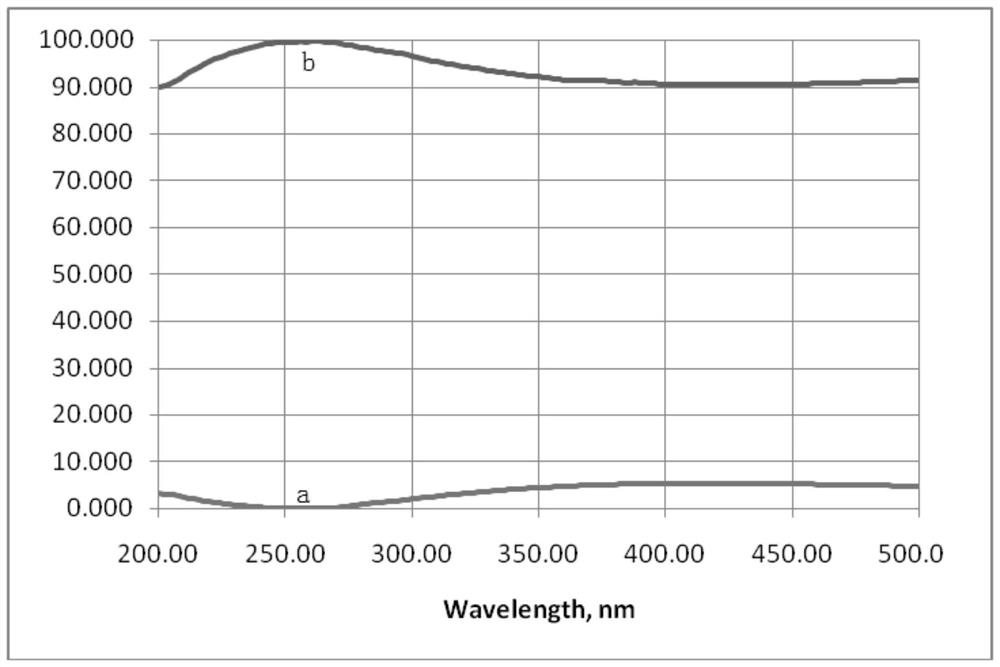

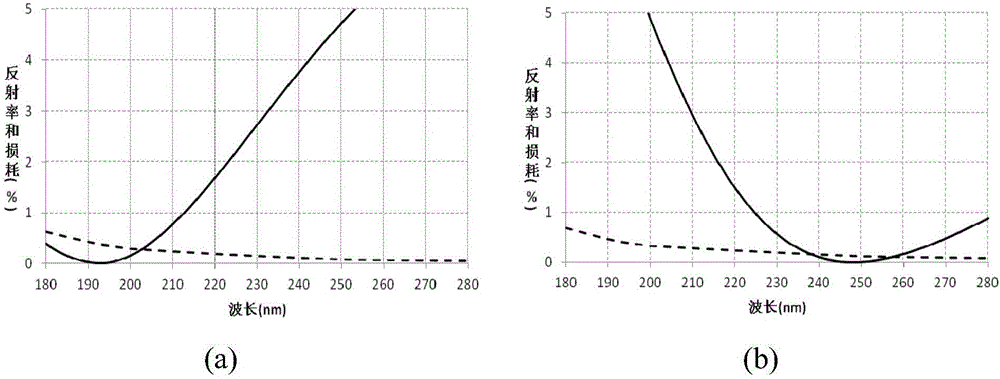

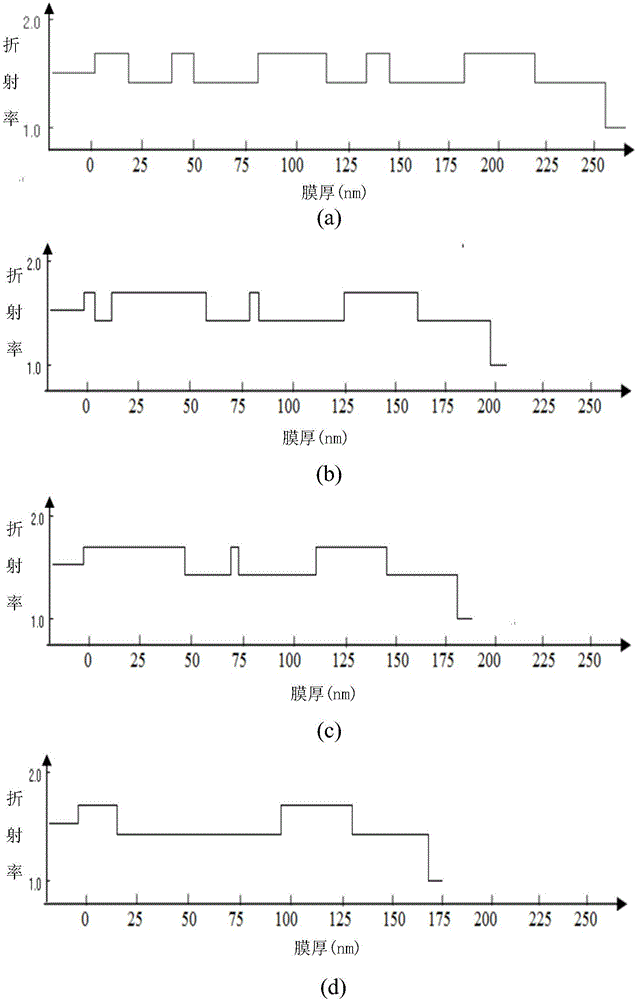

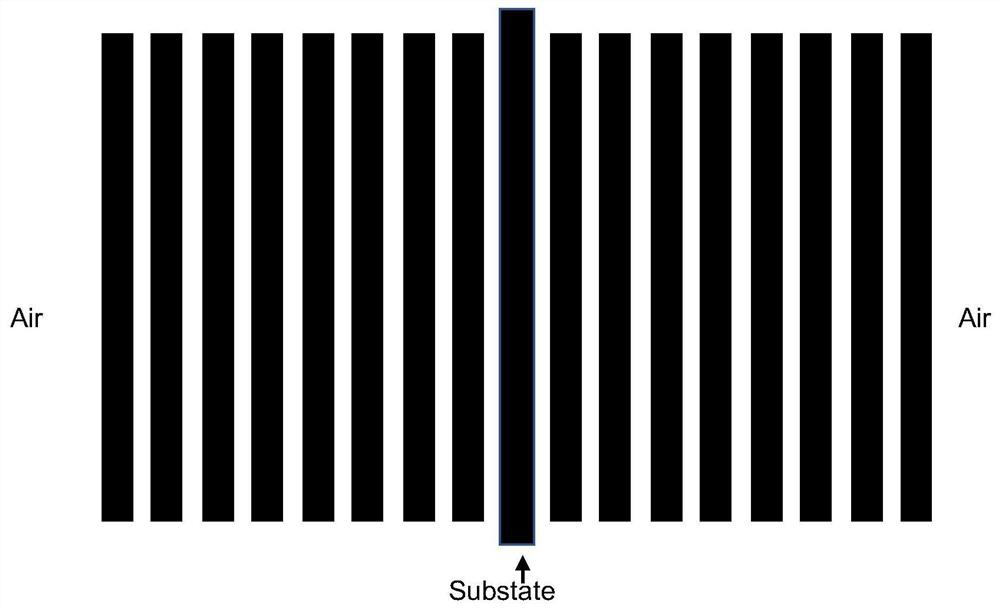

266-nanometer high-power laser antireflection film and preparation method thereof

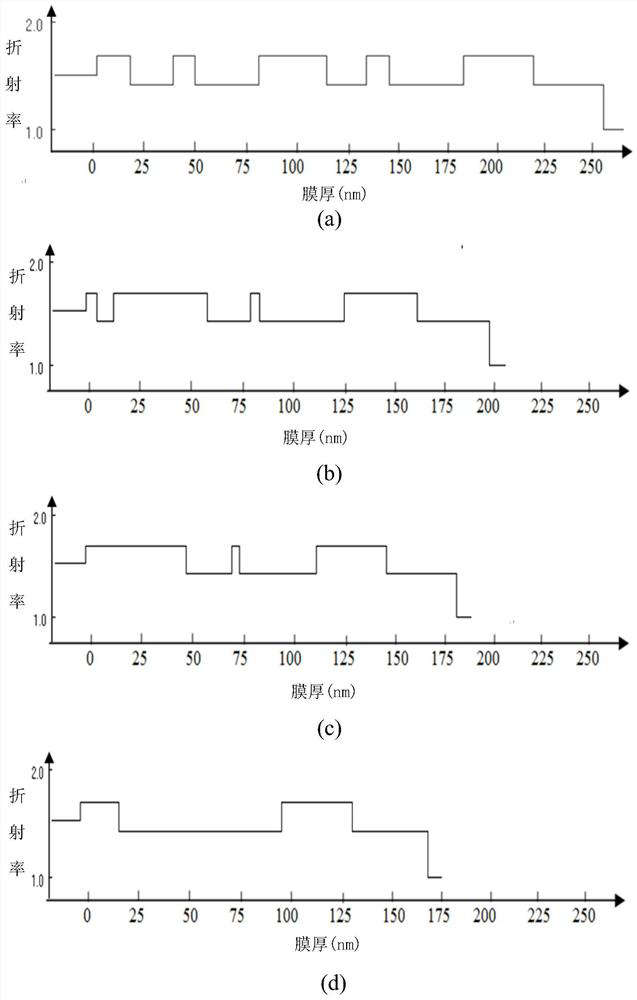

PendingCN112782791AHigh resistance to laser damage thresholdIncreased resistance to photodamage thresholdOptical elementsRefractive indexUltraviolet

The invention discloses a 266-nanometer high-power laser antireflection film and a preparation method thereof, the 266 nanometer high-power laser antireflection film has a film layer structure of A / cL / bH / aL / SUB / aL / bH / cL / A, wherein SUB represents a glass substrate, A represents air, H represents a high-refractive-index film layer, L represents a low-refractive-index film layer, a, b and c are coefficients of the quarter reference wavelength optical thickness of each film layer respectively, a is 1.6 + / -0.2, b is 0.53 + / -0.2, and c is 1.13 + / -0.2. The 266-nanometer high-power laser antireflection film has a high laser damage resistance threshold in the ultraviolet band, the transmittance of the antireflection film at the 266nm band can reach 99.9% or above, and the 266-nanometer high-power laser antireflection film not only has good spectral performance, but also has good mechanical stability and stability, and can meet some high-end applications in the current near-ultraviolet field.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD

Surface high reflective semiconductor saturable absorption mirror

InactiveCN1707882AHigh resistance to laser damage thresholdModulation Depth ReducedLaser detailsQuantum wellHigh surface

The saturable semiconductor absorption mirror with high surface reflectivity includes one substrate, one buffering layer formed on the substrate, one Bragg reflector made on the buffering layer and with high reflectivity, one quantum well made on the Bragg reflector and acting for light absorption and photocarrier relaxation, one high reflectivity film made on the quantum well with dielectric material and capable of lowering the modulation depth and reducing non-saturation loss.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

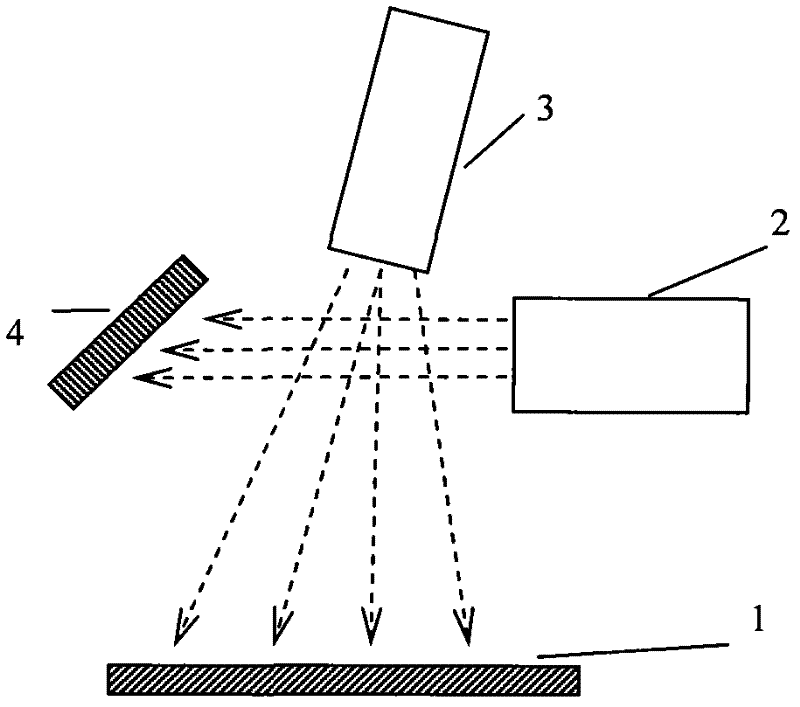

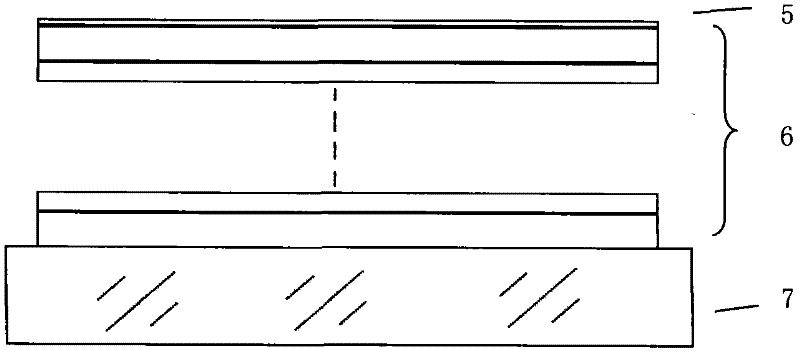

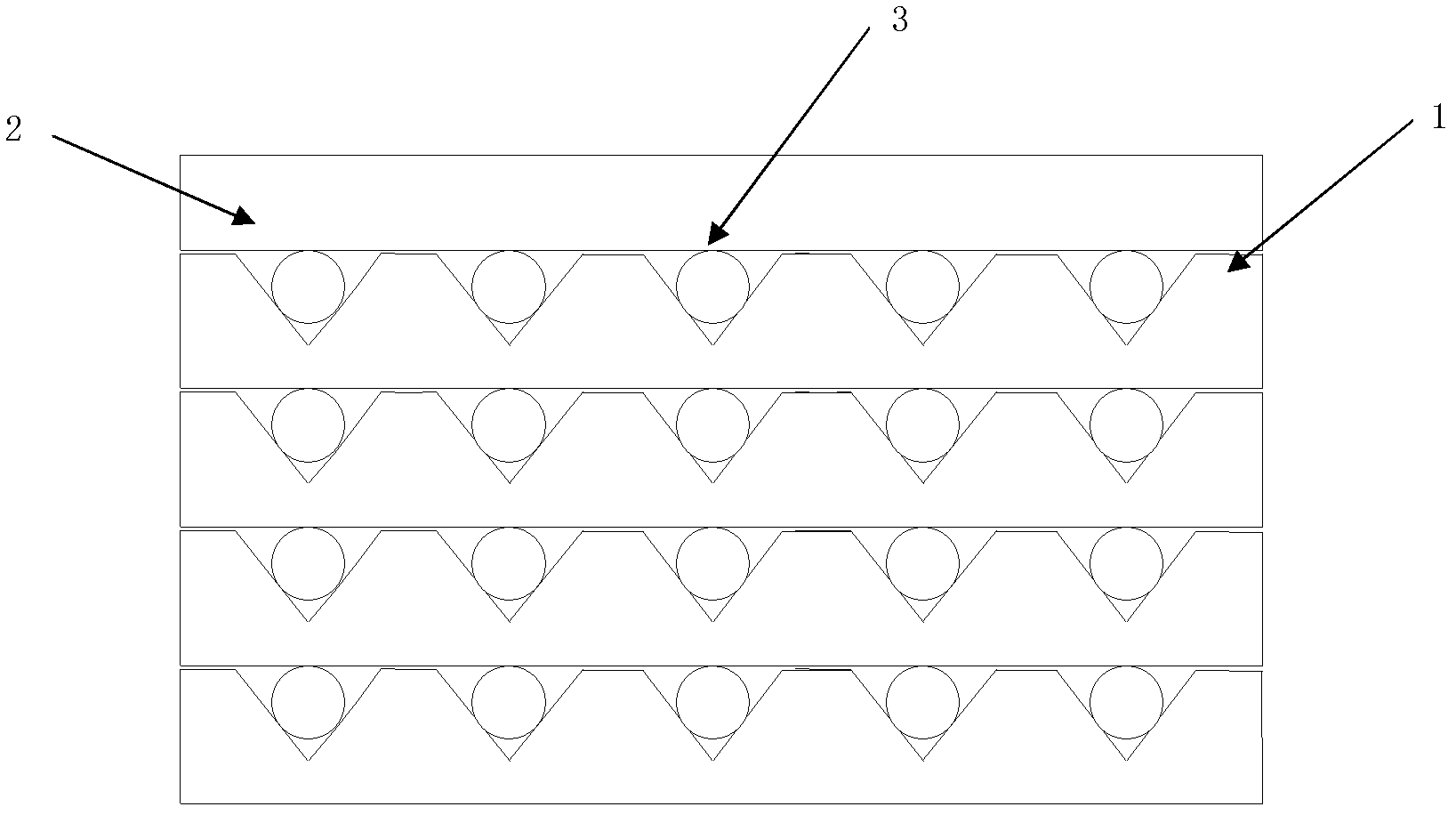

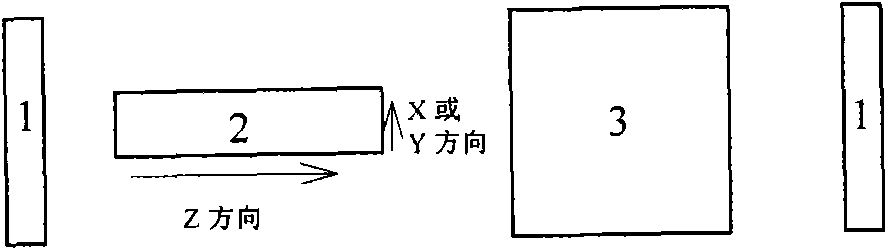

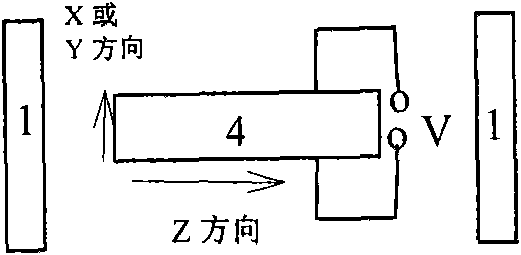

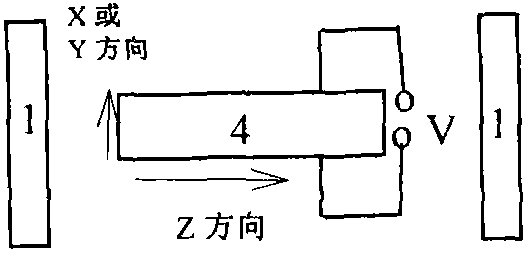

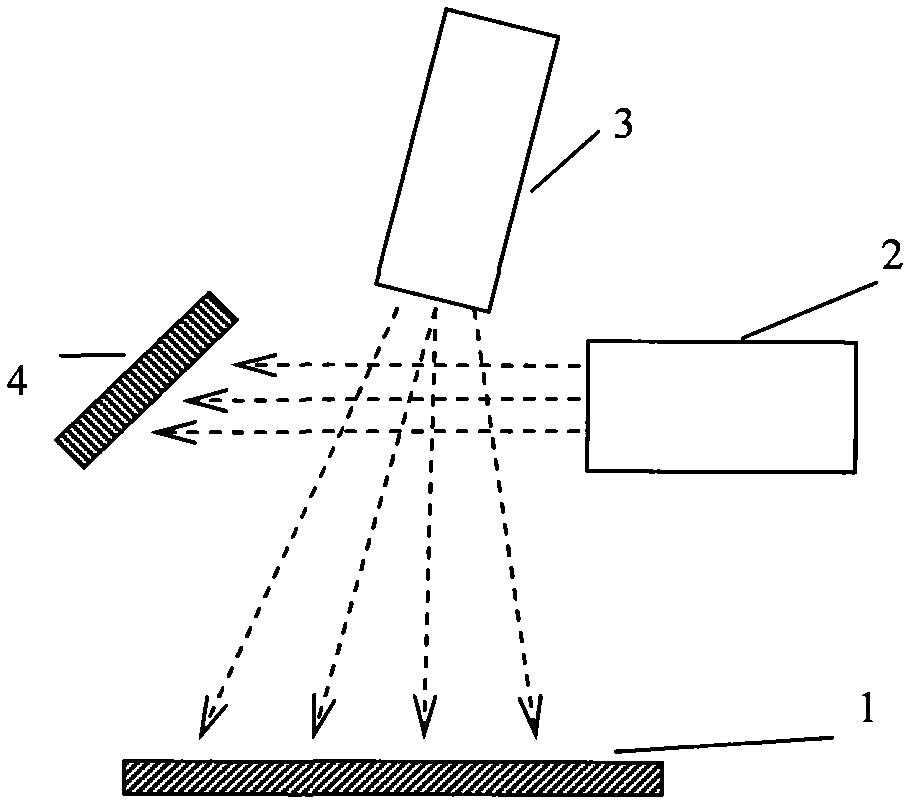

High-power laser beam sampler and high-power laser beam measuring system

ActiveCN102620817AIncrease powerReduced requirements to withstand laser exposurePhotometryHigh power lasersSignal processing circuits

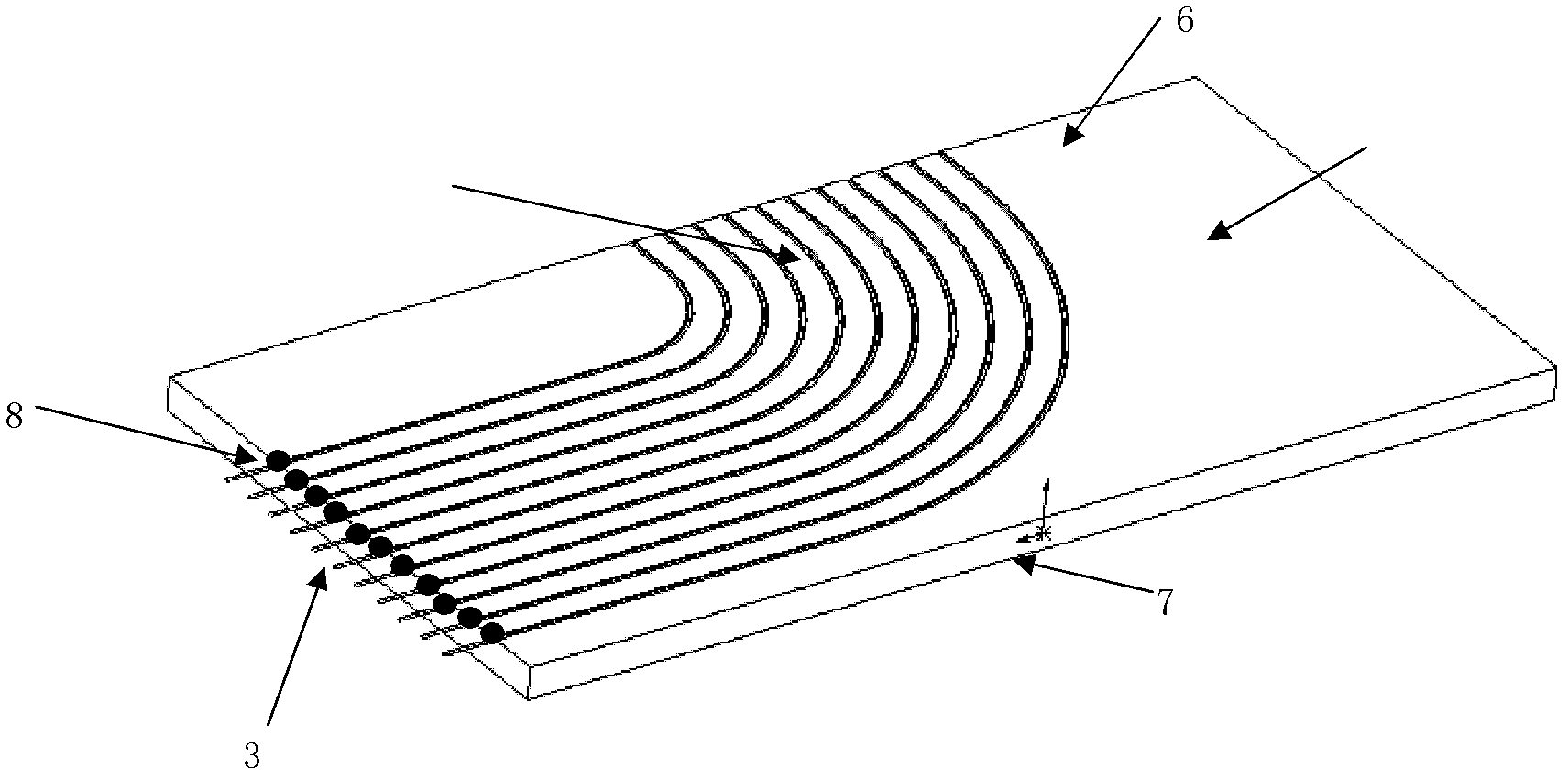

The invention discloses a high-power laser beam sampler and a high-power laser beam measuring system. The sampler comprises a plurality of optical fibers and laminated dielectric slabs, a plurality of parallel L-shaped groove arrays are arranged on the dielectric slabs, the optical fibers are arranged in L-shaped grooves, and an optical fiber incidence end faces a laser incidence direction, and an output end deviates from laser beams. The measuring system comprises the high-power laser beam sampler, a plurality of detectors, a signal processing circuit and a data acquisition processing unit. In the measuring system, by means of overlapping and clamping the optical fibers through the dielectric slabs, damage to the sampler caused by laser absorption of organic matters such as coating materials, glue or the like is avoided, and the threshold value of laser damage resistance of the sampler is improved. Besides, in application, the vast majority of laser is transmitted, only small parts of beams are sampled, the requirement of the system on bearing laser irradiation is lowered, and subsequent beams can be reused.

Owner:NORTHWEST INST OF NUCLEAR TECH

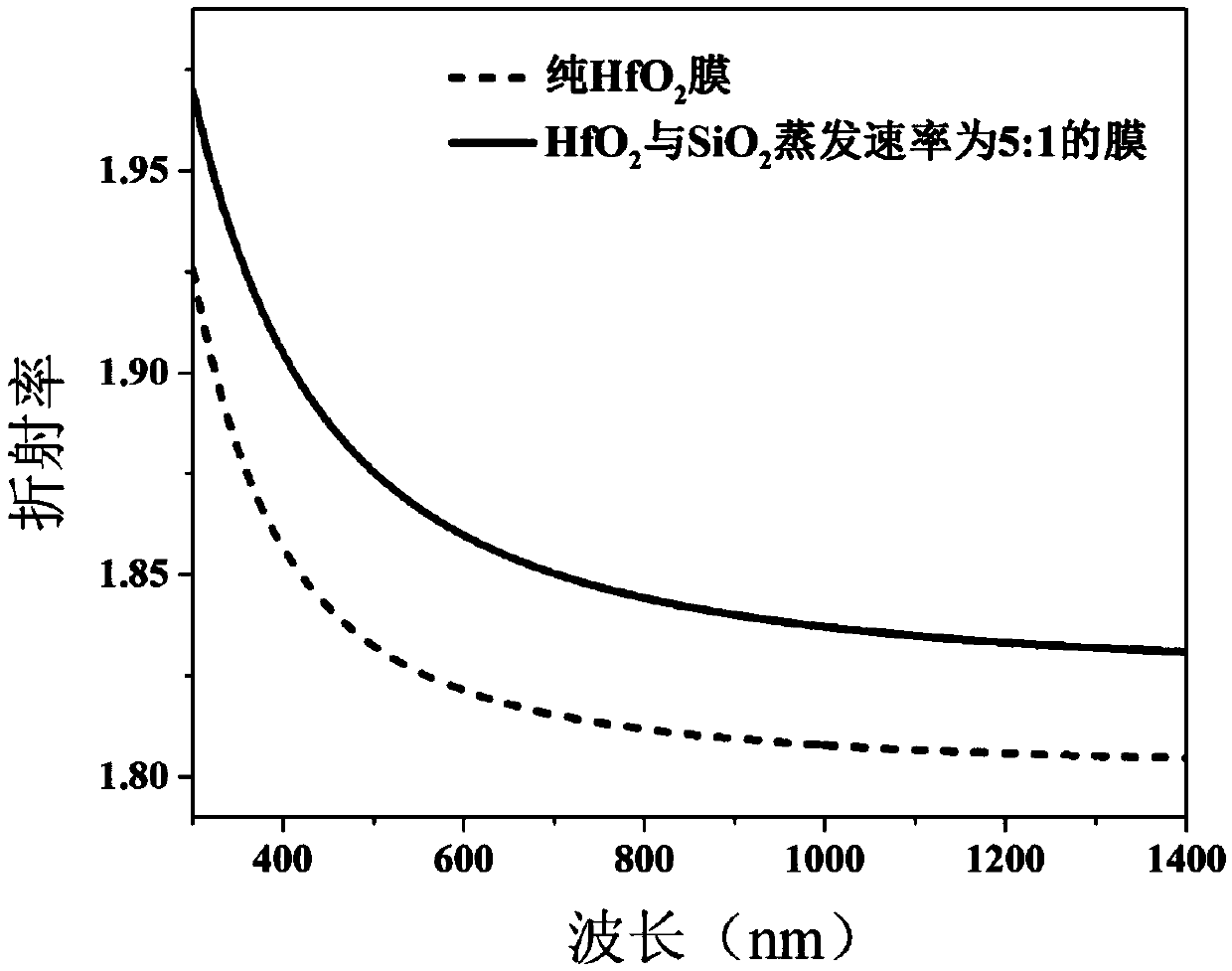

Method for raising refractive index of hafnium oxide film

InactiveCN105506560AHigh refractive indexAnti-laser damage threshold dropVacuum evaporation coatingSputtering coatingRefractive indexEvaporation

The invention provides a method for raising the refractive index of a hafnium oxide film. The HfO2 film is manufactured through electron beam evaporation plating, and the method is characterized in that HfO2 film materials of a first evaporation source are evaporated, SiO2 film materials of a second evaporation source are evaporated at the same time, and the proportion of the deposition rate UpsilonH of the HfO2 film materials to the deposition rate UpsilonL of the SiO2 film materials is greater than 4: 1. By means of the method, the refractive index of the film can be raised, and it is avoided that the laser damage resistance threshold value of the film declines due to negative factors such as film absorption and defect density raising. A certain proportion of SiO2 is mixed into the HfO2 film, the band gaps of the film are increased, and thereby the laser damage resistance threshold value of the film can be raised to a certain degree.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

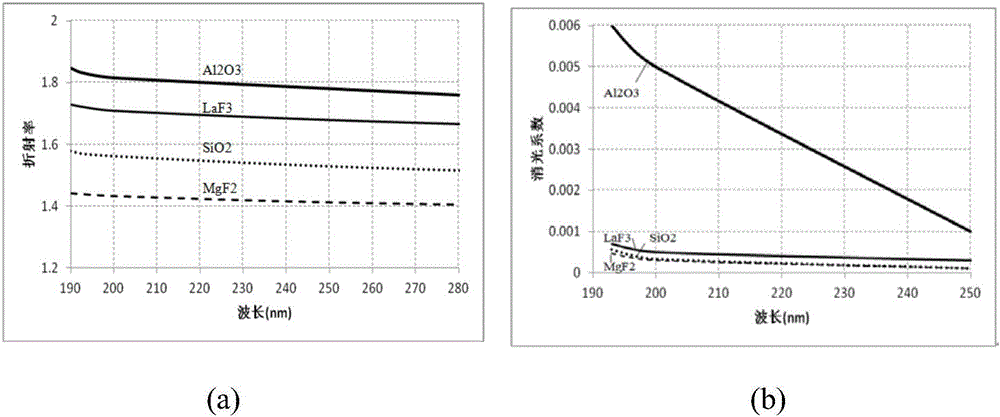

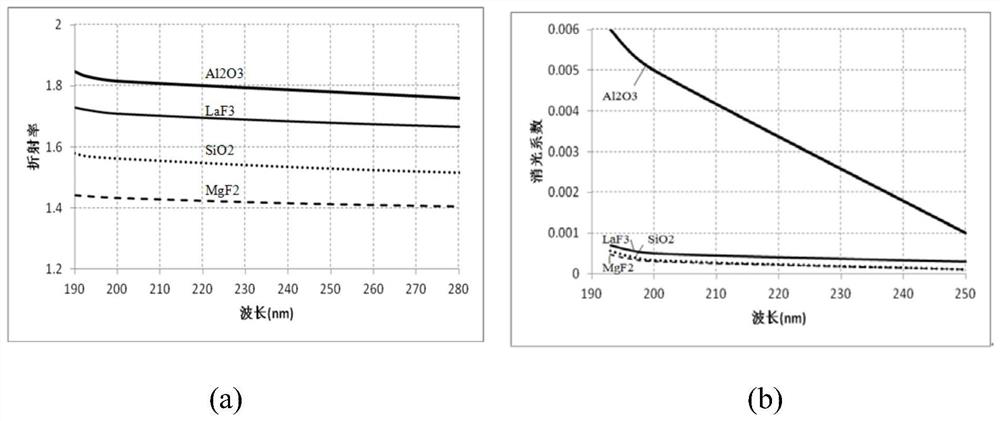

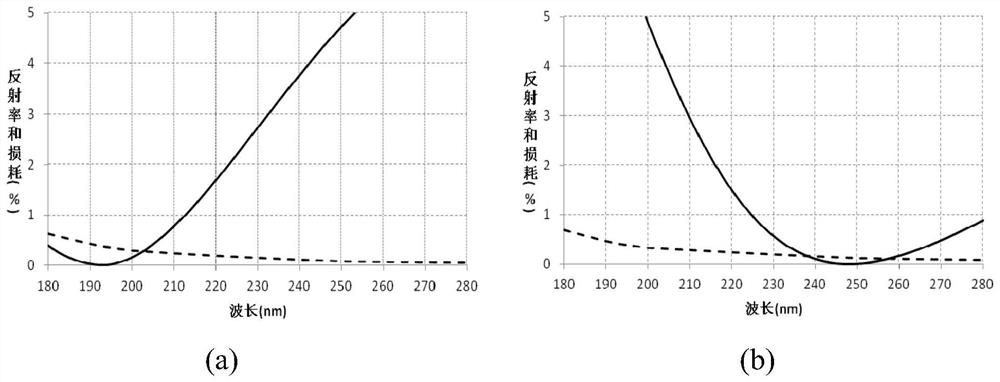

Dual wavelength antireflection film for excimer laser and optical film thickness monitoring system

The invention discloses a dual wavelength antireflection film for excimer laser and an optical film thickness monitoring system that are applied to an excimer laser device compatible with 193 nm and 248 nm deep ultraviolet. The dual wavelength antireflection film for the excimer laser comprises a substrate and a multilayer film arranged on the substrate, wherein the multilayer film is formed by alternating stacking high refractive index films and low refractive index films, each high refractive index film is made of lanthanum fluoride, each low refractive index film is made of magnesium fluoride, and the multilayer film has 4 to 10 layers. The optical film thickness monitoring system comprises an electron-beam evaporation source, a thermal resistance evaporation source and a plated substrate; a baffle plate is arranged between the electron-beam evaporation source as well as the thermal resistance evaporation source and a plated substrate. The dual wavelength antireflection film applied to deep ultraviolet excimer laser ranges from 193 nm to 248 nm and is very low in residual reflectivity of a substrate surface, and minimum absorbing and scattering loss can be realized.

Owner:HANGZHOU KOTI OPTICAL TECH

Laser-irradiation-resistant diffuse reflection metal panel and manufacturing method thereof

ActiveCN102407624AHigh resistance to laser damage thresholdAvoid damageMetal layered productsSand blastingDiffuse reflection

The invention discloses a laser-irradiation-resistant diffuse reflection metal panel and a manufacturing method thereof. After a metal base plate is subjected to sand blasting so as to become a diffuse surface, a zinc film, a nickel film and a golden film are sequentially coated on the diffuse surface, the laser-resistant damage threshold of the metal panel can be improved effectively, and at the same time, the damage of a component on the optical path caused by mirror reflectors is avoided.

Owner:NORTHWEST INST OF NUCLEAR TECH

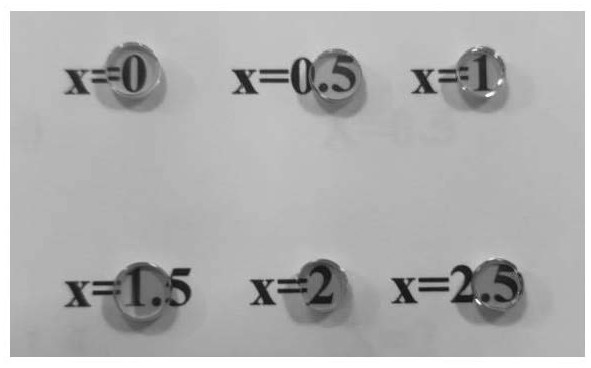

Self-adjusting Q laser crystal material and purpose thereof

InactiveCN102403649AWith electro-optic modulation propertiesHigh resistance to laser damage thresholdLaser detailsRare earth ionsOptoelectronics

The invention relates to a self-adjusting Q laser crystal and a purpose of the self-adjusting Q laser crystal. A chemical formula of the self-adjusting Q laser crystal is Na3La9-xRExB8O27, wherein x is more than 0 and is less than 9, RE is one or two of Pr3+, Nd3+, Sm3+, Dy3+, Ho3+, Er3+, Tm3+ and Yb3+ rare earth ions; the self-adjusting Q laser crystal belongs to a D3h-62m point group; a linear electro-optical coefficient matrix only includes an electro-optical coefficient gamma 22; and the electro-optical coefficient gamma 22 is equal to 2.3 pm / V. The self-adjusting Q laser crystal has the advantages of no deliquescence, high laser induced damage threshold and the like and can be used for manufacturing a self-adjusting Q laser device with a simple and compact structure.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

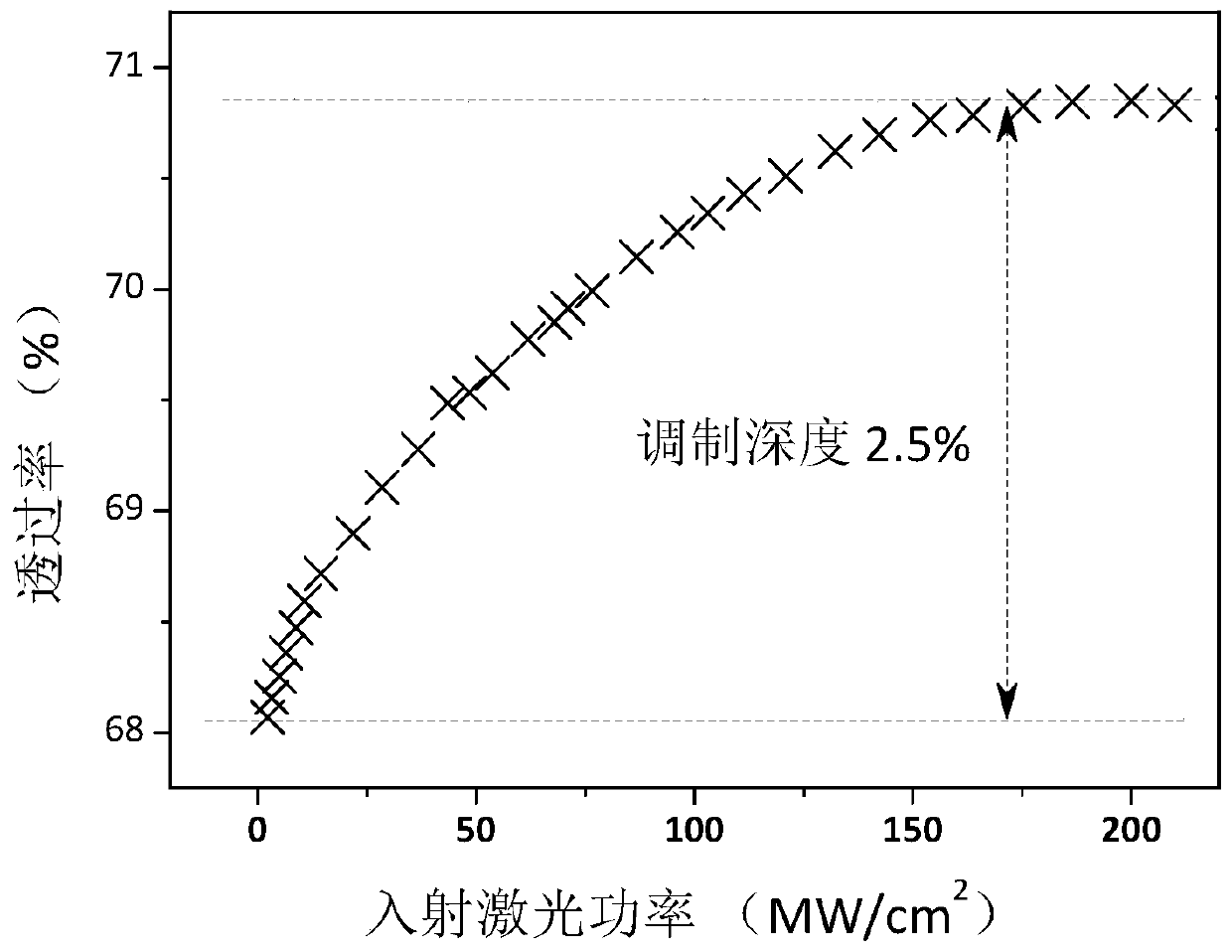

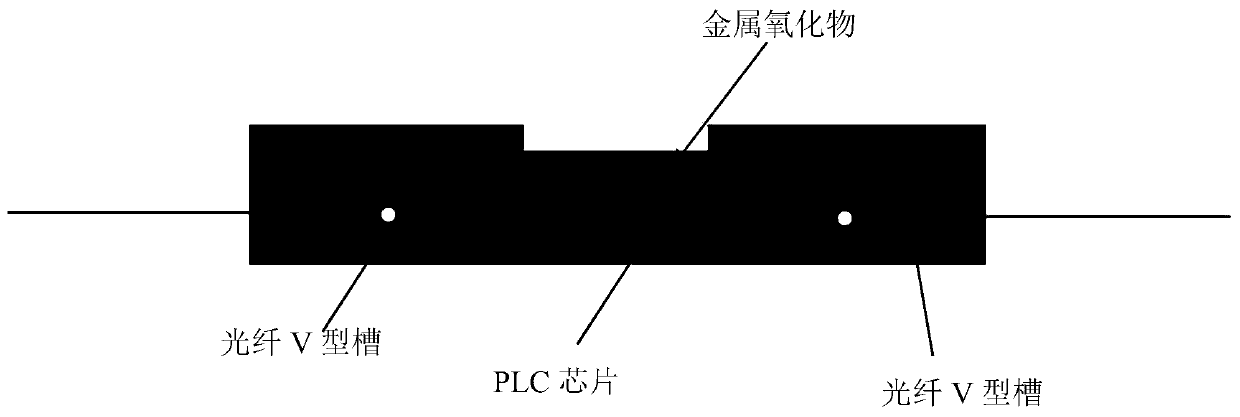

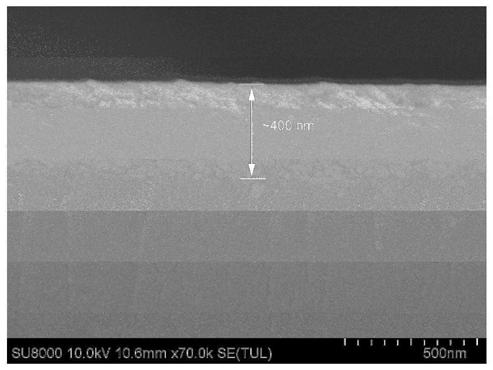

Saturable absorber based on planar optical waveguide and preparation method thereof

InactiveCN110350389AIncrease modulation depthHigh resistance to laser damage thresholdLaser detailsSemiconductor lasersVisible near infraredLaser damage

Owner:ZHEJIANG UNIV

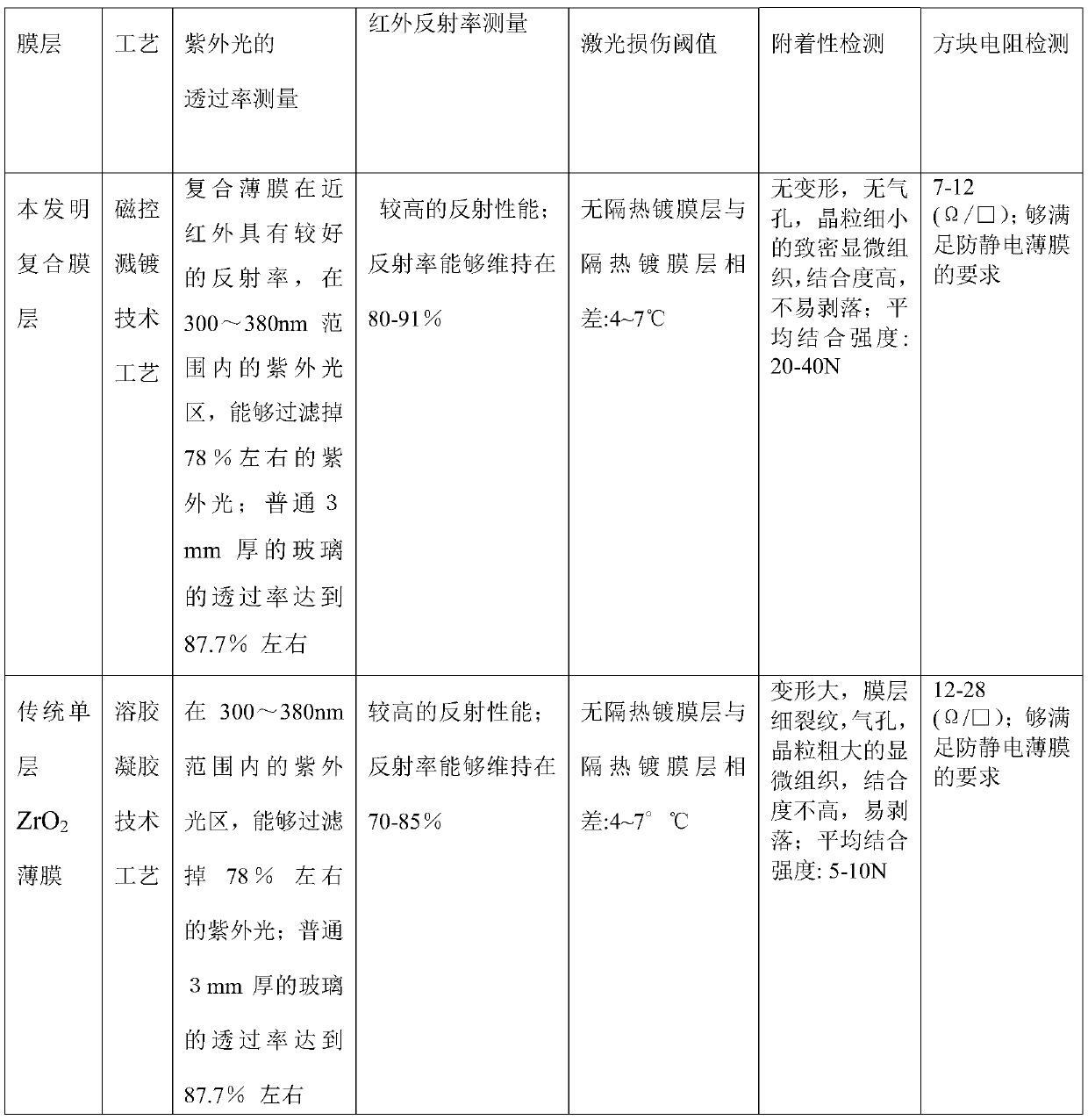

Chromium-nitride-stabilized zirconium oxide vacuum coating material and manufacturing method thereof

InactiveCN105369198AHigh resistance to laser damage thresholdImprove stabilityVacuum evaporation coatingSputtering coatingRefractive indexChromium nitride

The invention provides a chromium-nitride-stabilized zirconium oxide vacuum coating material and a manufacturing method thereof. Raw materials of the chromium-nitride-stabilized zirconium oxide vacuum coating material comprise, by mole, 75% to 98% of zirconium oxide and 2% to 25% of chromium nitride, and a proper amount of a polyvinyl alcohol bonding agent is added. The manufacturing method of the chromium-nitride-stabilized zirconium oxide vacuum coating material includes the following steps that firstly, zirconium oxide powder and chromium nitride powder serve as the raw materials, the raw materials are weighed according to the selected mole percents and evenly mixed, the polyvinyl alcohol bonding agent is then added, and the powder is agglomerated, pelletized and formed; secondly, the particle materials are pre-sintered, wherein the pre-sintering temperature is 1200 DEG C; and thirdly, the materials are sintered in a vacuum sintering furnace and then naturally cooled to the indoor temperature. By the adoption of the chromium-nitride-stabilized zirconium oxide vacuum coating material, the problems that a traditional zirconium oxide coating material is unstable and the refraction rate of the traditional zirconium oxide coating material is uneven in the coating process are solved, and the damage threshold value of a zirconium oxide film is increased.

Owner:WUXI HUIMING ELECTRONICS TECH

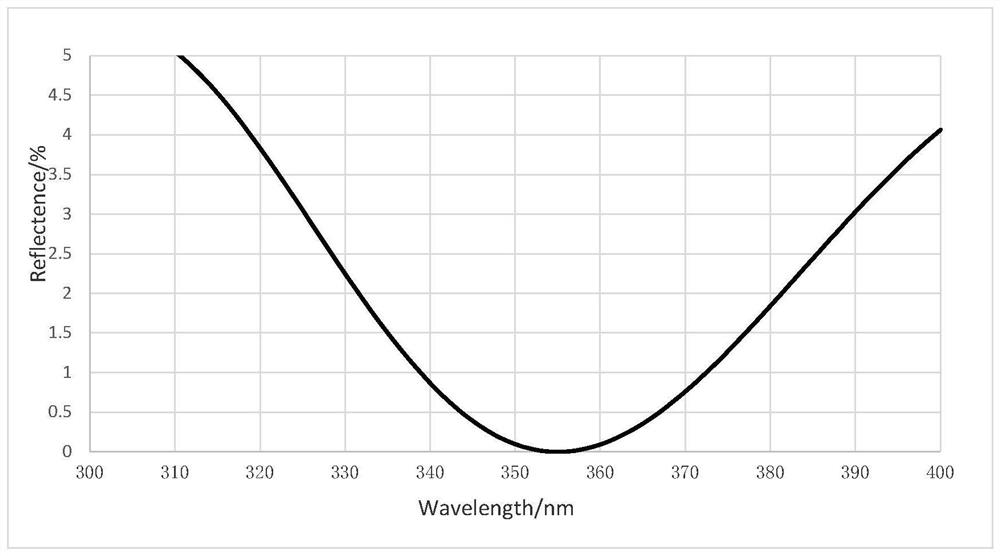

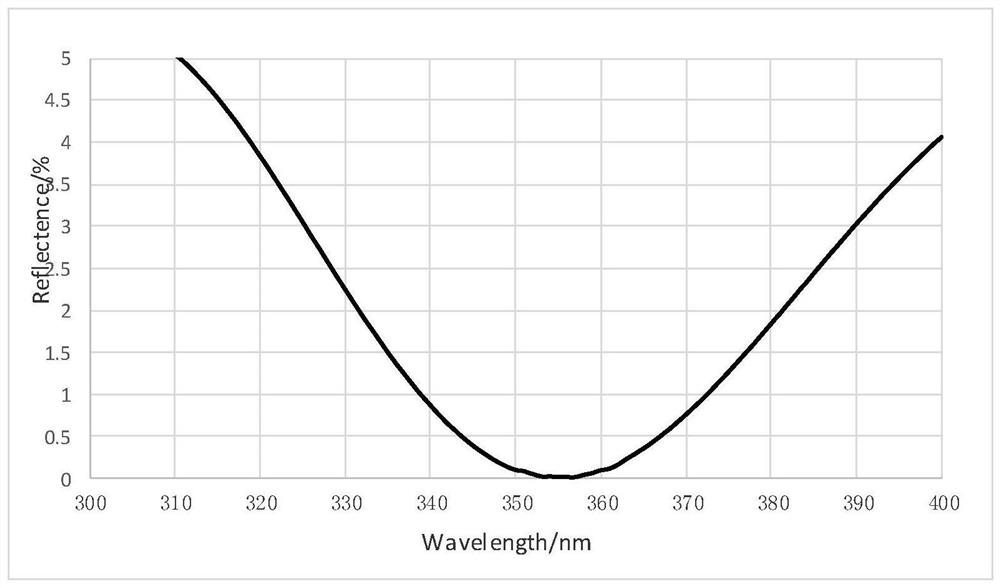

Ultraviolet band ultra-low absorption double-sided antireflection film and preparation method thereof

The invention discloses an ultraviolet band ultra-low absorption double-sided antireflection film and a preparation method thereof, and the structure of the ultraviolet band ultra-low absorption double-sided antireflection film is Air / (biLaiH) m / Sub / (aiHbiL) m / Air, wherein Sub represents a substrate; m is the number of cycles, and m is an integer from 2 to 6; H represents a high-refractive-index film layer, and the refractive index of the high-refractive-index film layer is 1.5-3; L represents a low-refractive-index film layer, and the refractive index of the low-refractive-index film layer is 1-1.5; ai and bi respectively represent the optical thickness coefficient of each film layer, the numerical values are related to the reference wavelength lambda, (ai lambda) is more than or equal to 0 and less than or equal to 200, and (bi lambda) is more than or equal to 0 and less than or equal to 200. According to the ultraviolet band ultra-low absorption double-sided antireflection film, the film system design and the process are improved, 355nm ultraviolet antireflection is realized by plating the film systems on the surfaces of the two sides of the ultraviolet window glass substrate with the thickness of 5mm, the absorption is reduced, the transmittance is improved, the average transmittance is greater than 99.5%, and the single-sided reflection is less than 0.15%.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD

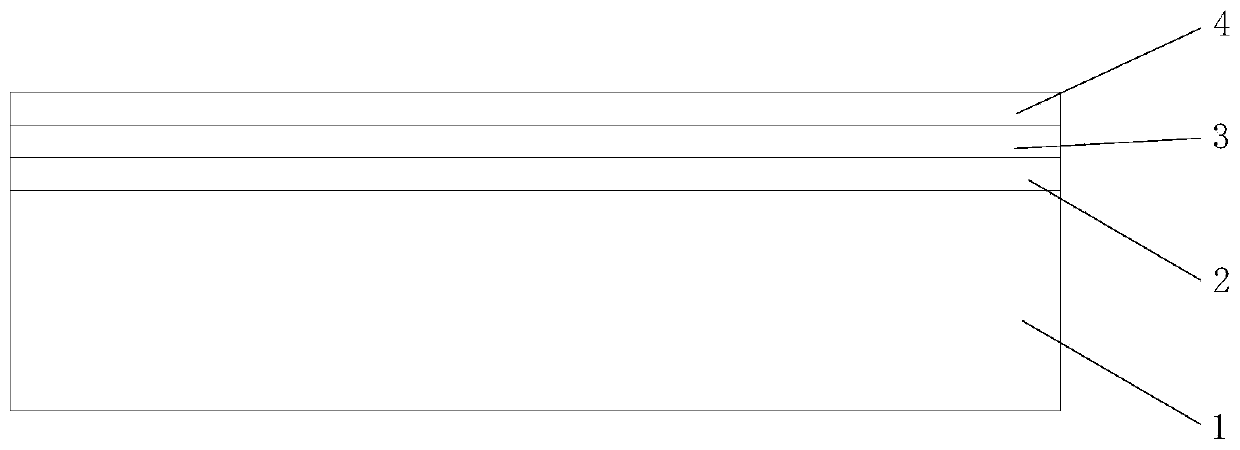

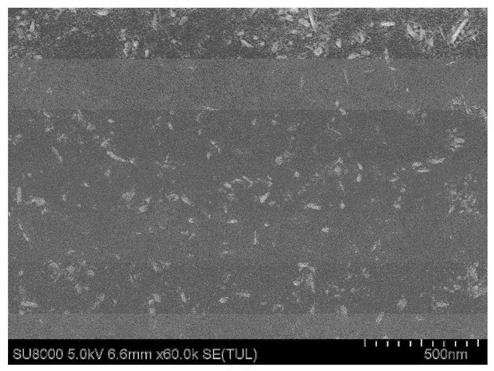

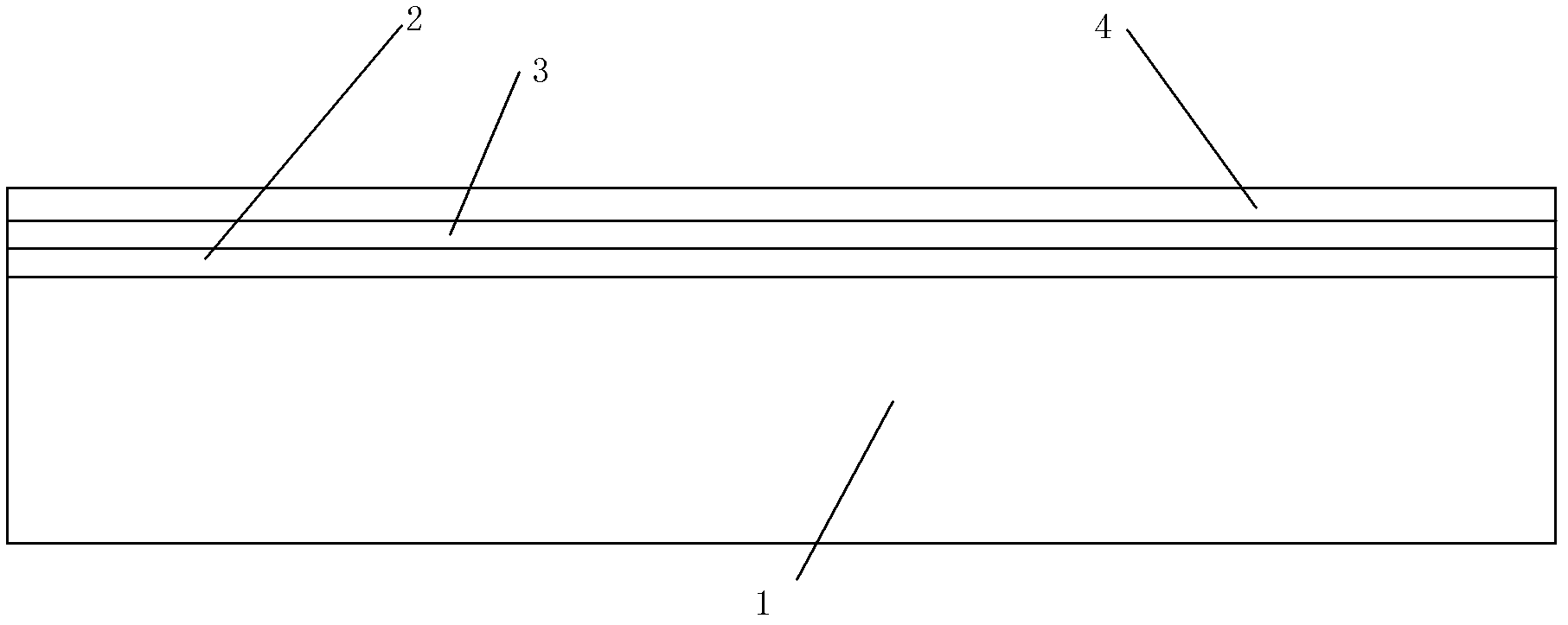

Anti-reflection and anti-laser-damage glass and preparation method thereof

The invention discloses anti-reflection and anti-laser-damage glass and a preparation method thereof. The glass comprises a substrate. A composite film layer is arranged on the surface of the substrate and sequentially comprises an inner layer, a middle layer and an outer layer from inside to outside, wherein the inner layer is a SiO2 layer, the middle layer is a (SiO2+ZrO2) layer, and the outer layer is a ZrO2 layer. The antireflection and anti-laser-damage effects of the glass can be effectively improved.

Owner:FUJIAN UNIV OF TECH

Titanium dioxide nano-porous coating and preparation method thereof

The invention discloses a titanium dioxide nano-porous coating and a preparation method thereof. The coating comprises a TiO2 nanoparticle porous film which is coated on a substrate and has a thickness of 100-700 nm, wherein the particle size of TiO2 nanoparticles is 20-30 nm, and the diameter of pores in the porous film is 8-10 nm. The preparation method comprises the steps: adding a mixed liquiddropwise to an acidic mixed aqueous solution firstly, wherein the mixed liquid and the acidic mixed aqueous solution are prepared separately; and then performing stirring so as to obtain TiO2 sol, then adding polyvinylpyrrolidone to the TiO2 sol, performing stirring so as to obtain mixed sol, then adding ethanol to the mixed sol, performing dilution and aging so as to obtain coating sol, then immersing a substrate in the coating sol for dip coating, then performing airing, then putting the obtained coated substrate at 480-520 DEG C, performing heat preservation, and then performing cooling soas to obtain the desired product. The structure is reasonable, the film layer has no easy cracking, and the titanium dioxide nano-porous coating can be commercialized in super-hydrophilic and infrared absorption fields easily and widely.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

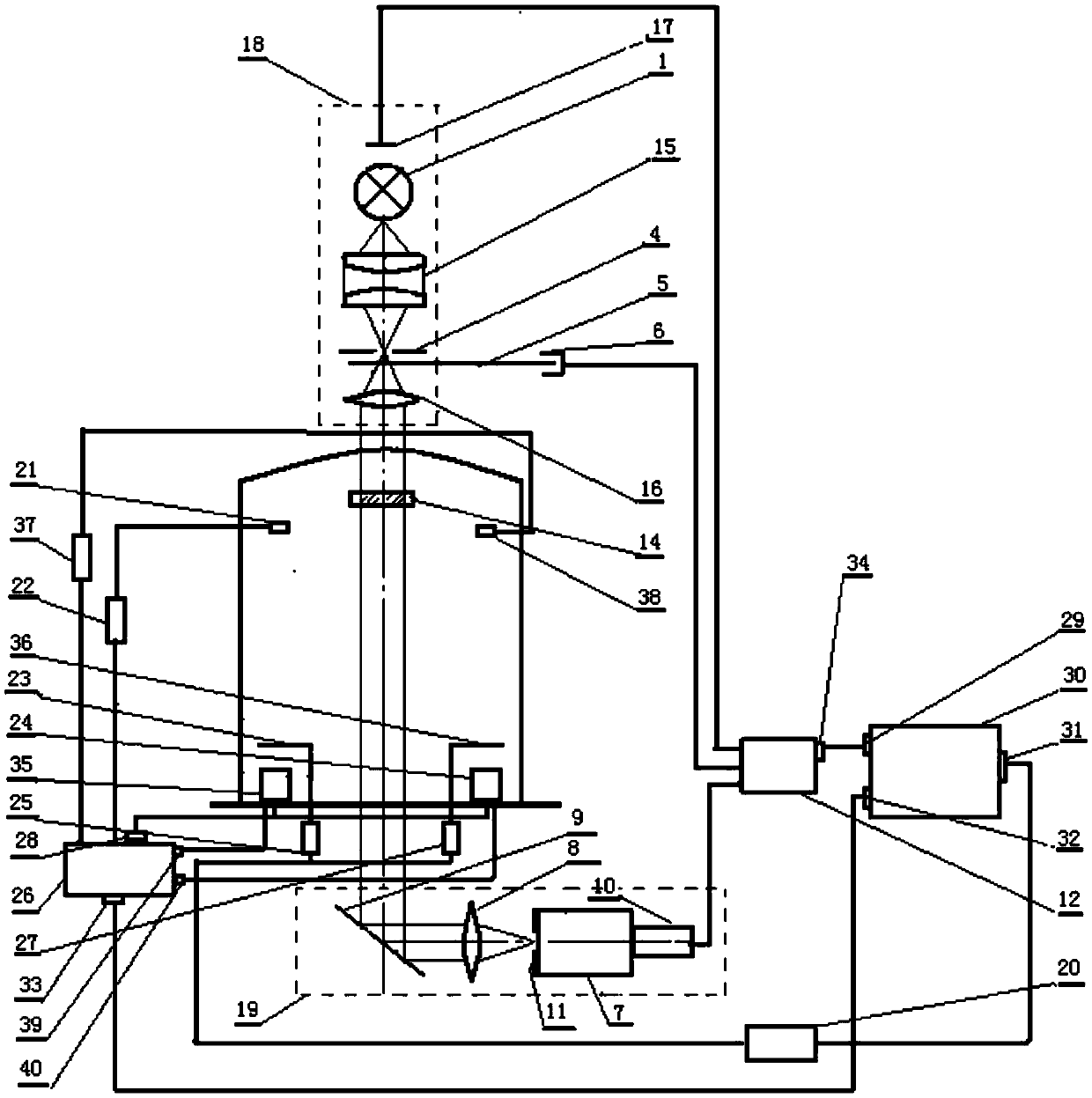

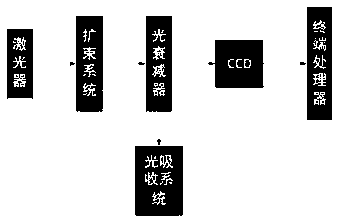

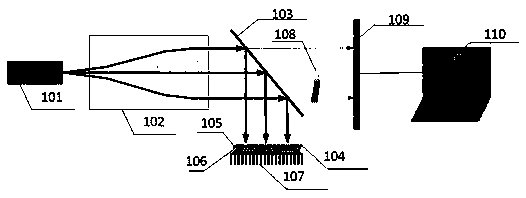

High-energy pulse laser range finder optical axis detection system and detection method

The invention provides a high-energy pulse laser range finder optical axis detection system and a detection method. The system is formed by a beam expanding system, a light attenuation system, a lightabsorption system, a CCD, a post-processing system and the like. Reflective attenuation with a higher anti-damage threshold is adopted. Most of a retroreflectance laser is processed by the light absorption system. The laser passes through a reflective optical attenuator and then is emitted to a variable optical attenuator so that different degrees of attenuation are performed on light. The laserpenetrating the variable optical attenuator is received by the CCD. A back-end processor carries out data processing on a light spot received by the CCD, and then uses an algorithm to accurately position the location of the center of mass so as to determine the position of a laser beam axis. In the invention, a novel grating-type light absorbing system is adopted to process a high-energy laser sothat the size of the system is greatly reduced and an entire measurement system is compact. The system and the method are suitable for more application scenes.

Owner:XIAN TECH UNIV

Laser-irradiation-resistant diffuse reflection metal panel and manufacturing method thereof

ActiveCN102407624BHigh resistance to laser damage thresholdAvoid damageMetal layered productsSand blastingDiffuse reflection

The invention discloses a laser-irradiation-resistant diffuse reflection metal panel and a manufacturing method thereof. After a metal base plate is subjected to sand blasting so as to become a diffuse surface, a zinc film, a nickel film and a golden film are sequentially coated on the diffuse surface, the laser-resistant damage threshold of the metal panel can be improved effectively, and at the same time, the damage of a component on the optical path caused by mirror reflectors is avoided.

Owner:NORTHWEST INST OF NUCLEAR TECH

Prepn. of laser damage-resisting wide-band antireflecting film

InactiveCN1167959CMild preparation conditionsLow costLiquid surface applicatorsCoatingsAlcoholPolyethylene glycol

A preparation method of laser damage-resisting wide-band antireflecting film with ethyl emtasilicate as presoma includes mixing water, absolute alcohol, polyvinyl pyrrolidone and polyglycol in a certain proportion in the presence of ammonia water catalyst, reaction by sufficient stirring, ageing, and film plating. The present invention has the advantages of mild preparation condition, low cost and simple operation, and the prepared SiO2 film has antireflecting performance of 400-600 nm bandwidth and high laser damage resistance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

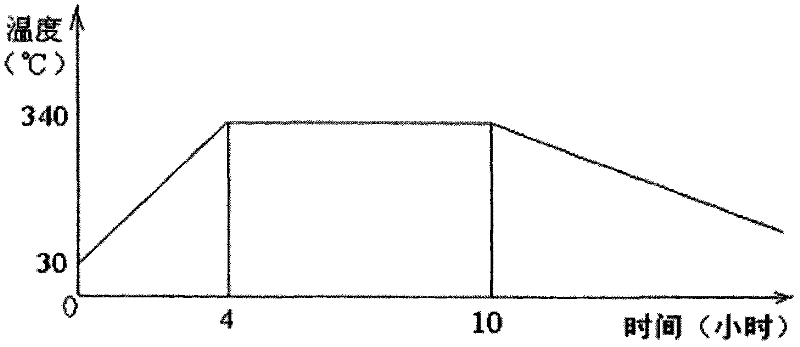

Reflecting mirror with low loss and high reliability

The invention relates to a reflecting mirror with high reliability for a laser gyro prepared through ion beam sputtering. The reflecting mirror is prepared by the following steps of: alternately plating a regularTiO2 / SiO2 film high reflective coating with 1 / 4 working wavelength on a nano-grade quartz base by adopting a double-ion-beam sputtering and depositing process, plating a layer of extremely thin air interface layer material HfO2 at the outermost layer, and carrying out postprocessing under the condition of 340 DEG C / 6h on a reflecting mirror film in the air after the plating is finished. The reflecting mirror provided by the invention has extremely low loss and dispersion, a high laser damage resistant threshold, heat stability within 340 DEG C and favorable plasma discharging environment resisting capacity and can keep stable optical property of over 15000Sec in an environment with the plasma energy of 200w. The reflecting mirror prepared by using the technology provided by the invention has stable working property in a gyro resonator, has high environment reliability and can meet the application requirement of a high-precision laser gyro.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

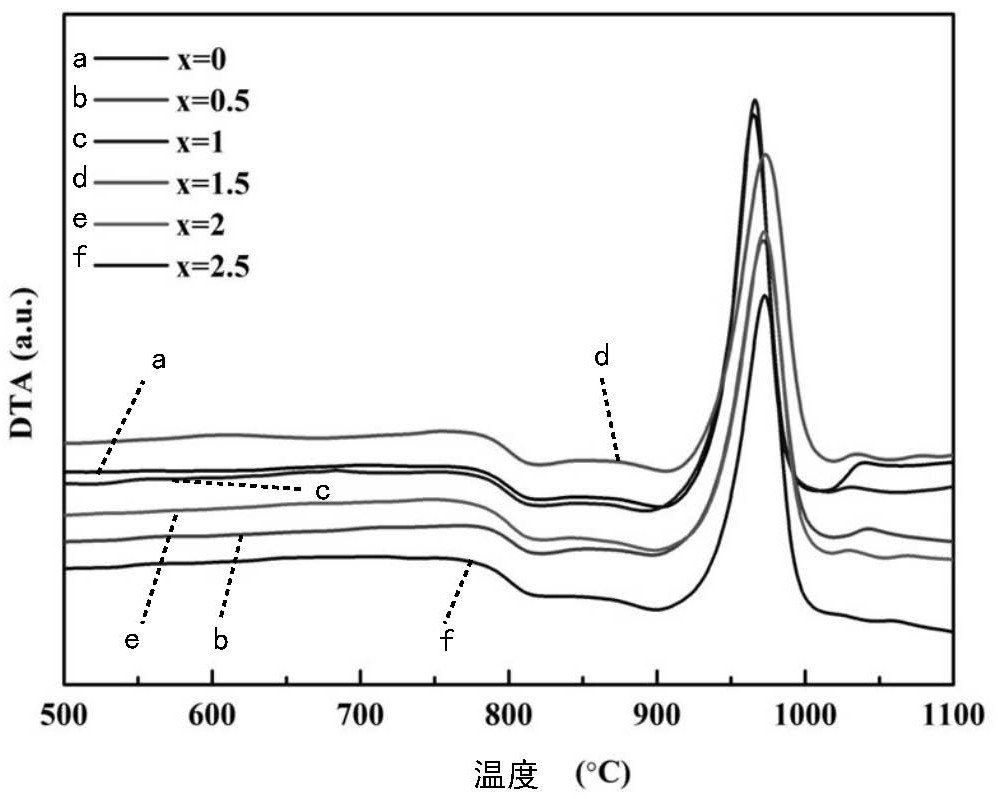

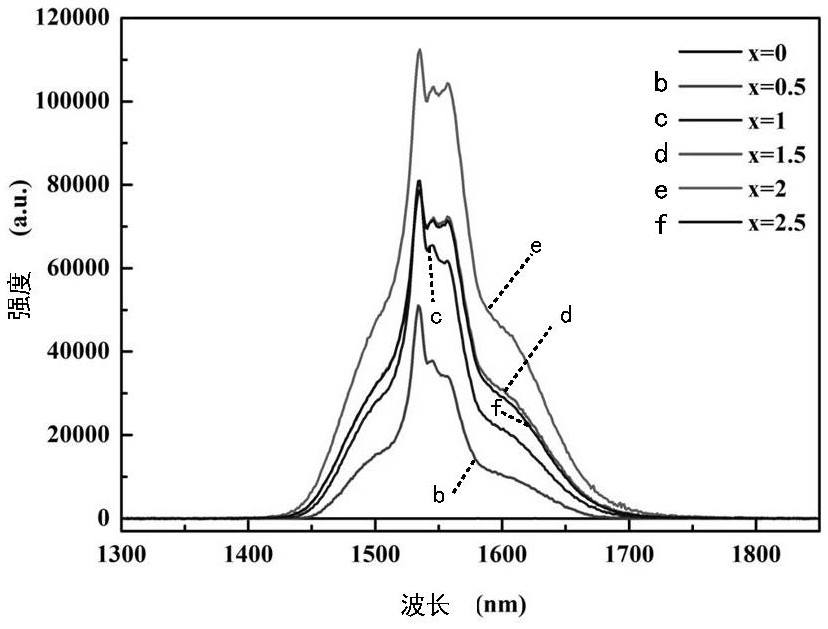

A near-infrared luminescent heavy metal oxide glass material with ultra-wide processing temperature range

The invention provides a near-infrared light-emitting heavy metal oxide glass material with an ultra-wide processing temperature range. The near-infrared luminescent heavy metal oxide glass material contains Ga 2 o 3 , La 2 o 3 、 Ta 2 o 5 and Er 2 o 3 As the main component, and containing 54.8 to 55.2 mol% of Ga relative to 100 mol parts of the main component 2 o 3 , 32.5-35 mol% La 2 o 3 , 9.9~10.1% mol% Ta 2 o 5 , and Er greater than 0 mol% and less than 2.5 mol% 2 o 3 .

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation of membrane for preventing injury from laser beam

InactiveCN1109254CRaw materials are easy to getLow costCoatingsOptical elementsOptoelectronicsPreventing injury

A process for preparing the anti-reflecting film with high power to prevent laser damage includes such technological steps as proportionally mixing raw materials, stirring, ageing at 20-60 deg.C for 10-180 days in sealed container to obtain SiO2 sol as filing liquid, and rotational filming to obtain anti-reflecting film. Its advantages include easily available raw materials, low cost, simple preparing process, high transmissive rate up to 100% and high threshold of laser damage.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

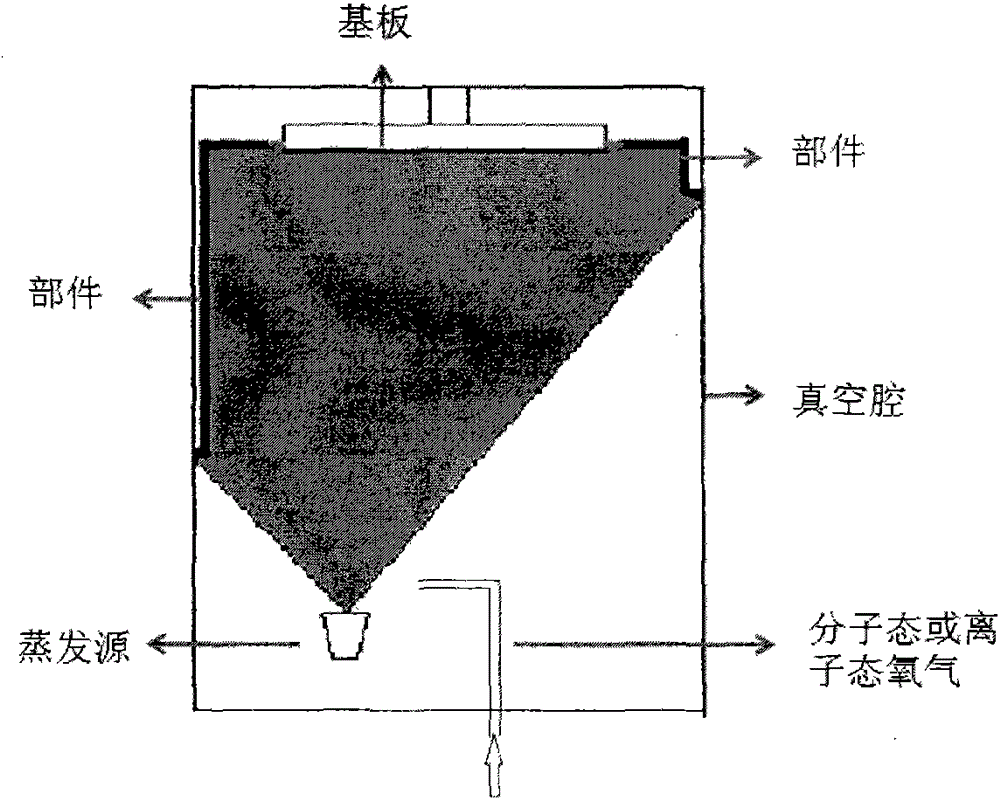

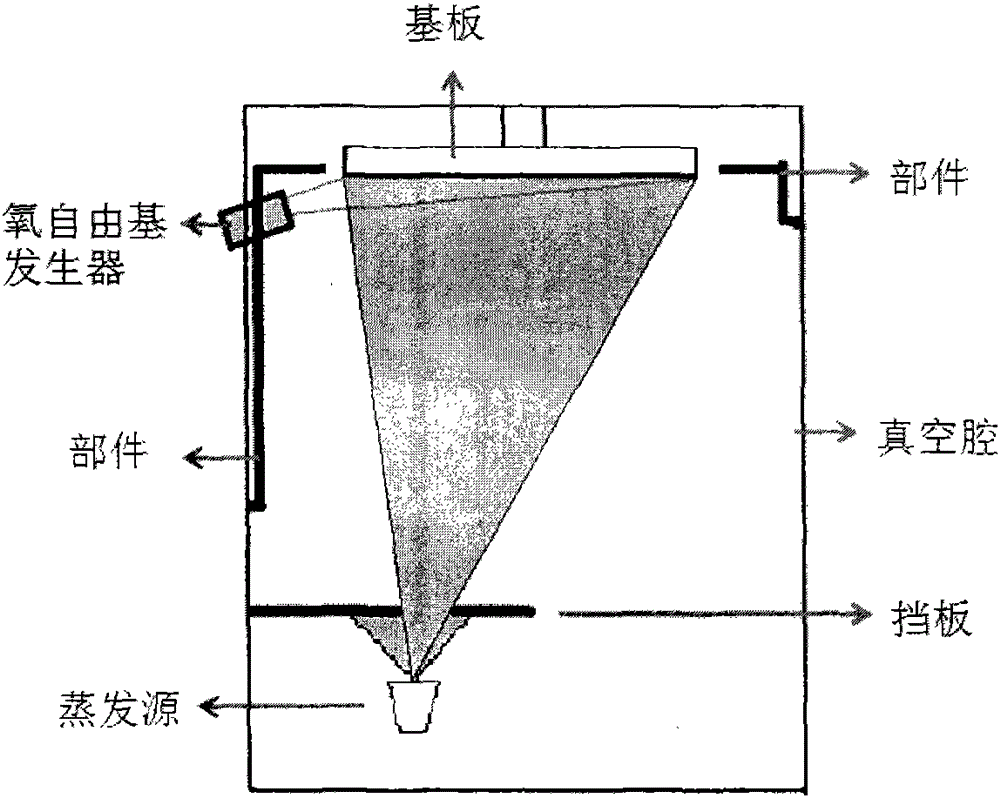

An Evaporation Method for Improving the Anti-laser Damage Threshold of Oxide Thin Films

ActiveCN103882385BReduce intrinsic absorptionLow extinction coefficientVacuum evaporation coatingSputtering coatingEvaporationLaser damage

The invention belongs to the field of thin film optics, and in particular relates to an evaporation method for improving a laser induced damage threshold of an oxide film, mainly aiming at the key factors, which comprise the absorption and defects in films, and causes the damage in laser-induced film. The ineffective evaporation materials are blocked and adsorbed by adding an isolation baffle between the evaporation source and the substrate, thereby reducing the pollution to the vicinity of the substrate and decreasing the probability for defects formation in the film; oxygen radicals, which have stronger oxidization capability than conventional molecular oxygen and ions oxygen, are introduced into the vacuum chamber to allow oxygen radicals to be incident on the surface of the substrate so that the deposition material is possibly sufficiently oxidized under high vacuum conditions, and the absorption of the film is reduced, thereby obtaining the oxide film having higher threshold. The method not only retains the unique beneficial properties of the electron beam thermal evaporation method for plating a laser film and but also improves the intrinsic absorption and the defect density of the film; and the preparation method has the characteristics of strong pertinence, high quality and simplicity and feasibility.

Owner:润坤(上海)光学科技有限公司

A kind of preparation method of photo-stable nonlinear chalcogenide thin film

InactiveCN103572218BOptical BandgapIncreased Laser Damage ThresholdSelenium/tellurium compundsVacuum evaporation coatingEvaporationRefractive index

Owner:XUZHOU NORMAL UNIVERSITY

A dual-wavelength anti-reflection coating and optical film thickness monitoring system for excimer laser

The invention discloses a dual-wavelength anti-reflection film for excimer lasers and an optical film thickness monitoring system for preparing the anti-reflection film, so as to be applied to excimer laser instruments compatible with deep ultraviolet 193nm and 248nm. A dual-wavelength anti-reflection coating for excimer lasers, comprising a substrate and a multilayer film alternately formed of high-refractive-index films and low-refractive-index films arranged on the substrate in turn; the high-refractive index film is lanthanum fluoride, The low refractive index film is magnesium fluoride; the number of layers of the multilayer film is 4-10 layers. An optical film thickness monitoring system includes an electron beam evaporation source, a thermal resistance evaporation source, and a substrate to be plated. A baffle is arranged between the electron beam evaporation source, the thermal resistance evaporation source and the substrate to be plated. The dual-wavelength anti-reflection coating for deep ultraviolet excimer laser of the present invention not only has very low residual reflectivity of the substrate surface at the wavelengths of 193nm and 248nm, but also has the lowest absorption and scattering loss.

Owner:HANGZHOU KOTI OPTICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com