A kind of preparation method of photo-stable nonlinear chalcogenide thin film

A chalcogenide thin film and nonlinear technology, which is applied in the field of photo-stabilized nonlinear chalcogenide thin film and its preparation, can solve the problems of unstable optical properties, and achieve stable optical properties of devices, small changes in photo-induced refractive index, and consistent performance. Sexually controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

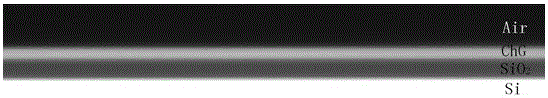

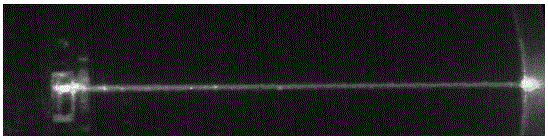

[0019] Example 1: The composition of the chalcogenide film is Ge 12 As 24 S 32 Se 32

[0020] The composition of particle size less than 2mm is Ge 12 As 24 S 32 Se 32 Put 5g of glass into the Ti evaporation boat in the cavity of the vacuum coating machine, add a buffer cover, and then put Si / SiO with a diameter of 4 inches and a thickness of 300 μm 2 (SiO 2 The thickness of the layer is 2μm) and the substrate is fixed on the rotating sample holder, the door of the chamber is closed tightly, and the vacuum in the chamber is evacuated to 10 -7 torr; Clean the substrate with an Ar ion gun for 120 seconds before coating, then heat up the evaporation boat, while monitoring the vacuum degree and thermal evaporation rate in the chamber during evaporation, and slowly adjust the heating

[0021] Power until the evaporation rate stabilizes to 6nm / min, at this time the pressure of the vacuum chamber is 4.0x10 -6 torr; when the thickness of the film reaches 1.2 μm, stop heati...

Embodiment 2

[0024] Example 2: The composition of the chalcogenide film is Ge 10 As 28 S 16 Se 46

[0025] The composition of particle size less than 2mm is Ge 10 As 28 S 16 Se 46 Put 5g of glass into the Ti evaporation boat in the cavity of the vacuum coating machine, add a buffer cover, and then put Si / SiO with a diameter of 4 inches and a thickness of 300 μm 2 (SiO 2 The thickness of the layer is 2μm) and the substrate is fixed on the rotating sample holder, the door of the chamber is closed tightly, and the vacuum in the chamber is evacuated to 10 -7 torr; Clean the substrate with an Ar ion gun for 90 seconds before coating, then heat up the evaporation boat, monitor the vacuum degree and thermal evaporation rate in the chamber during evaporation, and slowly adjust the heating power until the evaporation rate is stable to 12 nm / min, at this time the pressure of the vacuum chamber is 1.2x10 -5 torr; when the thickness of the film reaches 2.5 μm, stop heating, and slowly fi...

Embodiment 3

[0028] Example 3: The composition of the chalcogenide thin film is Ge 14 As 20 S 50 Se 16

[0029] The composition of particle size less than 2mm is Ge 14 As 20 S 50 Se 16 Put 5g of glass into the Ti evaporation boat in the cavity of the vacuum coating machine, add a buffer cover, and then put Si / SiO with a diameter of 4 inches and a thickness of 300 μm 2 (SiO 2 The thickness of the layer is 2μm) and the substrate is fixed on the rotating sample holder, the door of the chamber is closed tightly, and the vacuum in the chamber is evacuated to 10 -7 torr; Clean the substrate with an Ar ion gun for 60 seconds before coating, then heat up the evaporation boat, monitor the vacuum degree and thermal evaporation rate in the chamber during evaporation, and slowly adjust the heating power until the evaporation rate stabilizes to 18 nm / min, at this time the pressure of the vacuum chamber is 4.2x10 -5 torr; when the thickness of the film reaches 4.0 μm, stop heating, and slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com