Active layer, thin film transistor, array substrate, display device and manufacturing method

A thin-film transistor and active layer technology, applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as the inability to form a bottom-gate staggered structure and the difficulty in controlling the thickness of the gate insulating layer, achieving controllable thickness, Effect of wide optical bandgap and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] In the fifth aspect, an embodiment of the present invention provides a method for preparing an active layer. The method for preparing the active layer includes: preparing a zirconium indium oxide film with a preset thickness by DC sputtering, and then wet etching the pattern to obtain the active layer; wherein, as shown above, the chemical formula of zirconia indium is Zr x In 100-x o y , where 0.1≤x≤20, y>0.

[0066] It can be seen that the preparation method of the active layer provided by the embodiment of the present invention has the advantages of high film formation rate and simple process, and does not need to set a barrier layer on the active layer, which reduces the preparation cost.

[0067] Further, after wet etching the zirconia indium film, anneal the zirconia indium film at a temperature of 150-220° C. for at least 30 minutes in phosphoric acid with a mass concentration of 40%-60% to form the desired active layer. It can be seen that after the active l...

Embodiment 1

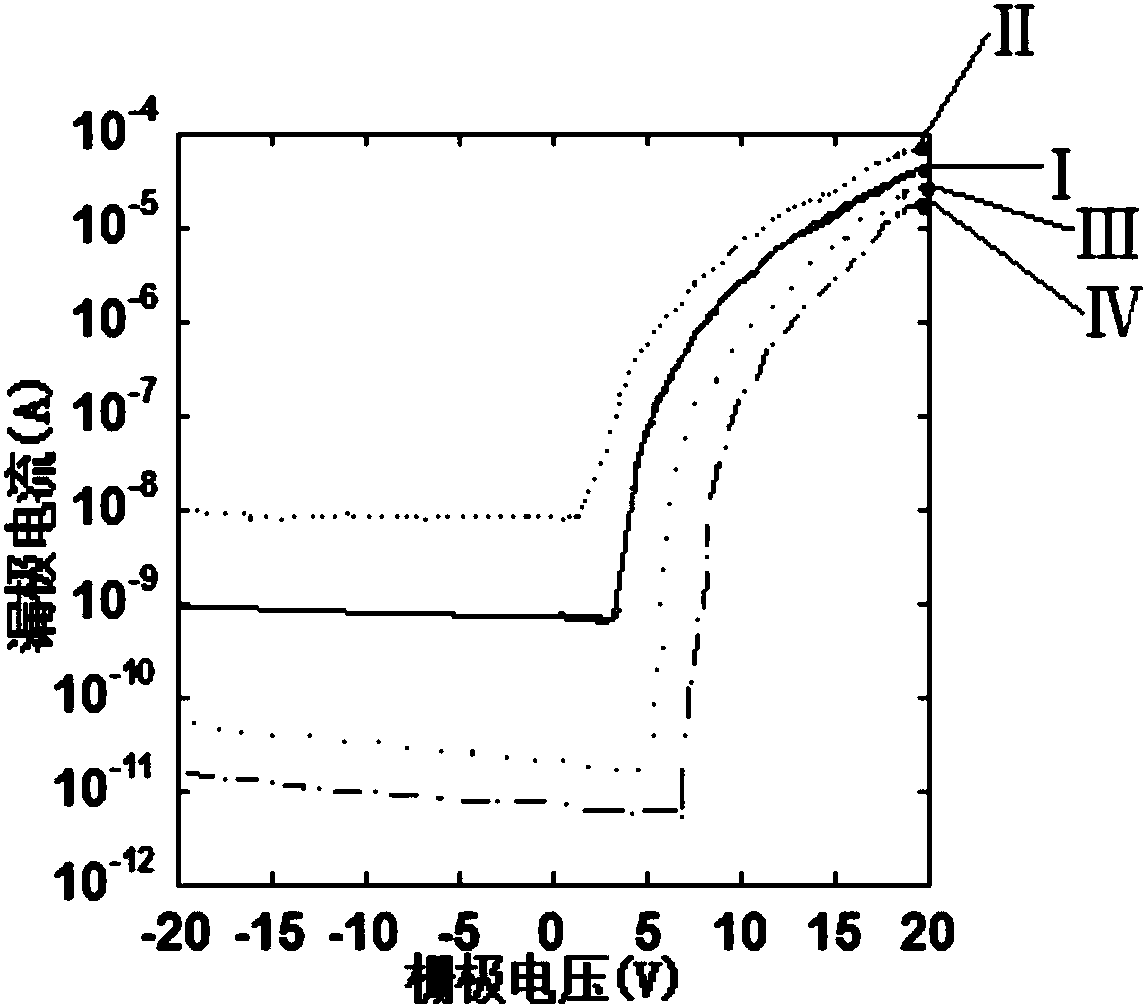

[0078] This embodiment provides an active layer, the thickness of which is 20nm, the material is zirconium oxide indium, and the chemical formula is Zr 1 In 91 o 100 , the carrier concentration is 1.5×10 18 cm -3 , with a carrier mobility of 31 cm 2 / Vs. Before the annealing, the etching rate of the active layer in the phosphoric acid of 50% mass concentration is equal to 60nm / min; The rate was 5 nm / min.

Embodiment 2

[0080] This embodiment provides an active layer with a thickness of 25nm, the material is zirconium oxide indium, and the chemical formula is Zr 6 In 94 o 100 , the carrier concentration is 1×10 18 cm -3 , with a carrier mobility of 30 cm 2 / Vs. Before the annealing, the etching rate of the active layer in the phosphoric acid of 50% mass concentration was equal to 65nm / min. The rate was 4nm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching rate | aaaaa | aaaaa |

| etching rate | aaaaa | aaaaa |

| carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com