A dual-wavelength anti-reflection coating and optical film thickness monitoring system for excimer laser

An excimer laser and dual-wavelength technology, applied in the field of deep ultraviolet excimer laser equipment, can solve the problems of film damage, high absorption, limited substrate materials, etc., and achieve the effect of increased difficulty and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

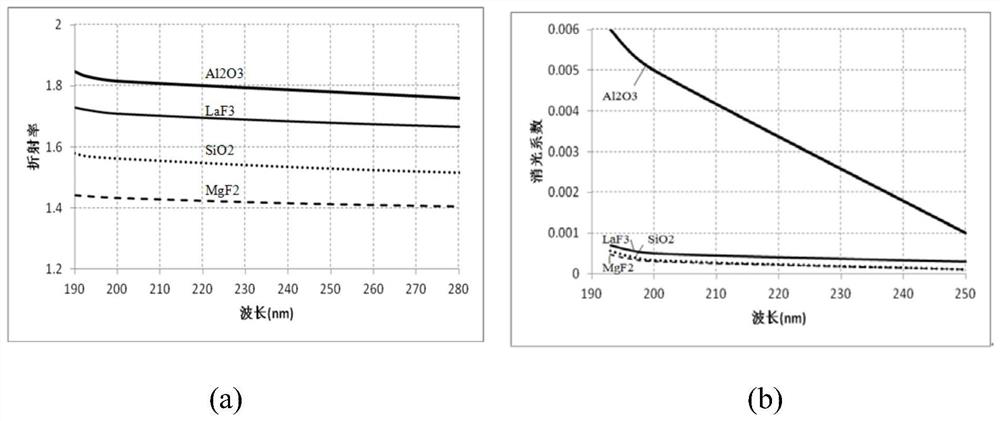

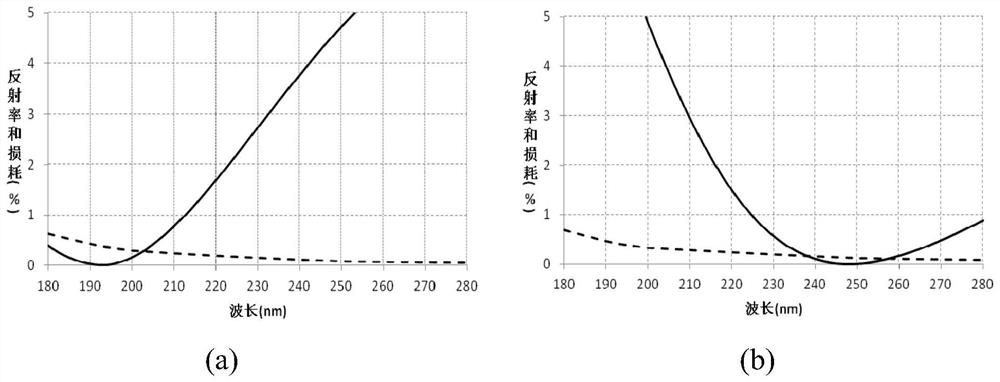

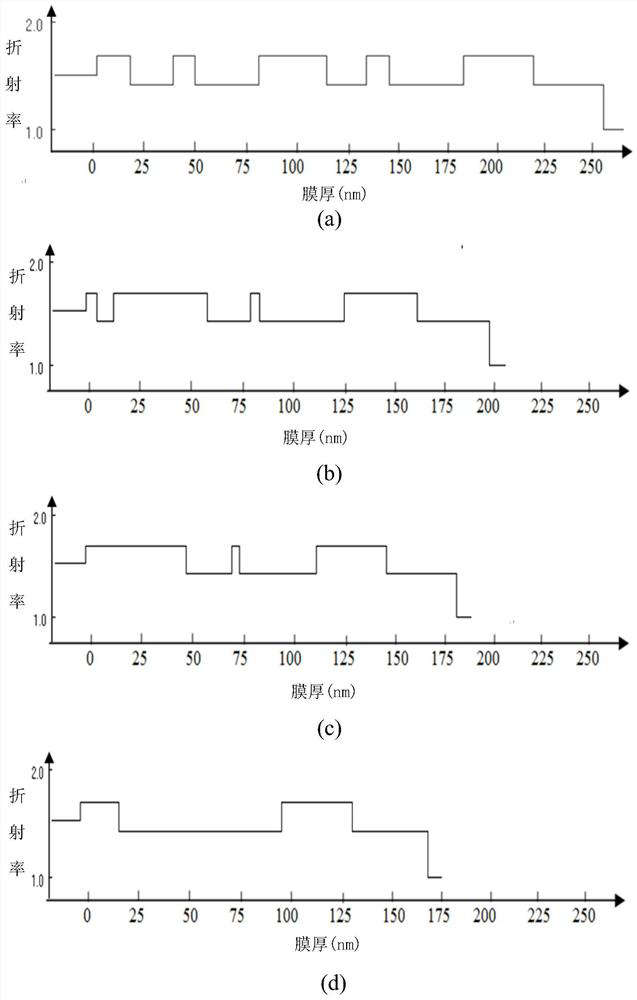

[0050] To implement the present invention, it is first necessary to search for high-refractive-index thin-film materials and low-refractive-index thin-film materials that are expected to be used in the deep ultraviolet band. Since the loss at a wavelength of 193nm is always greater than that at 248nm, materials that are applicable to a wavelength of 193nm must also be applicable to a wavelength of 248nm. In this way, the photon energy with a wavelength of 193nm and the electronic band gap can be used as the basis for preliminary screening of material loss. After screening, it is concluded that the high refractive index material has LaF 3 and Al 2 o 3 , and there are many low refractive index materials, such as MgF 2 , AlF 3 , CaF 2 and SiO 2 etc., but according to the combination of mechanical, chemical and optical properties, choose MgF 2 and SiO 2 more reasonable. Then, single-layer and multi-layer film evaporation experiments and optical constant test inversion were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com