High-power laser beam sampler and high-power laser beam measuring system

A laser beam and high-power technology, which is applied in the field of high-power laser beam sampler and high-power laser beam measurement system, can solve the problems of difficult application of high-power and high-energy laser, poor ability to withstand laser irradiation, etc., to improve Effects of resisting laser damage threshold, reducing angle sensitivity, and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

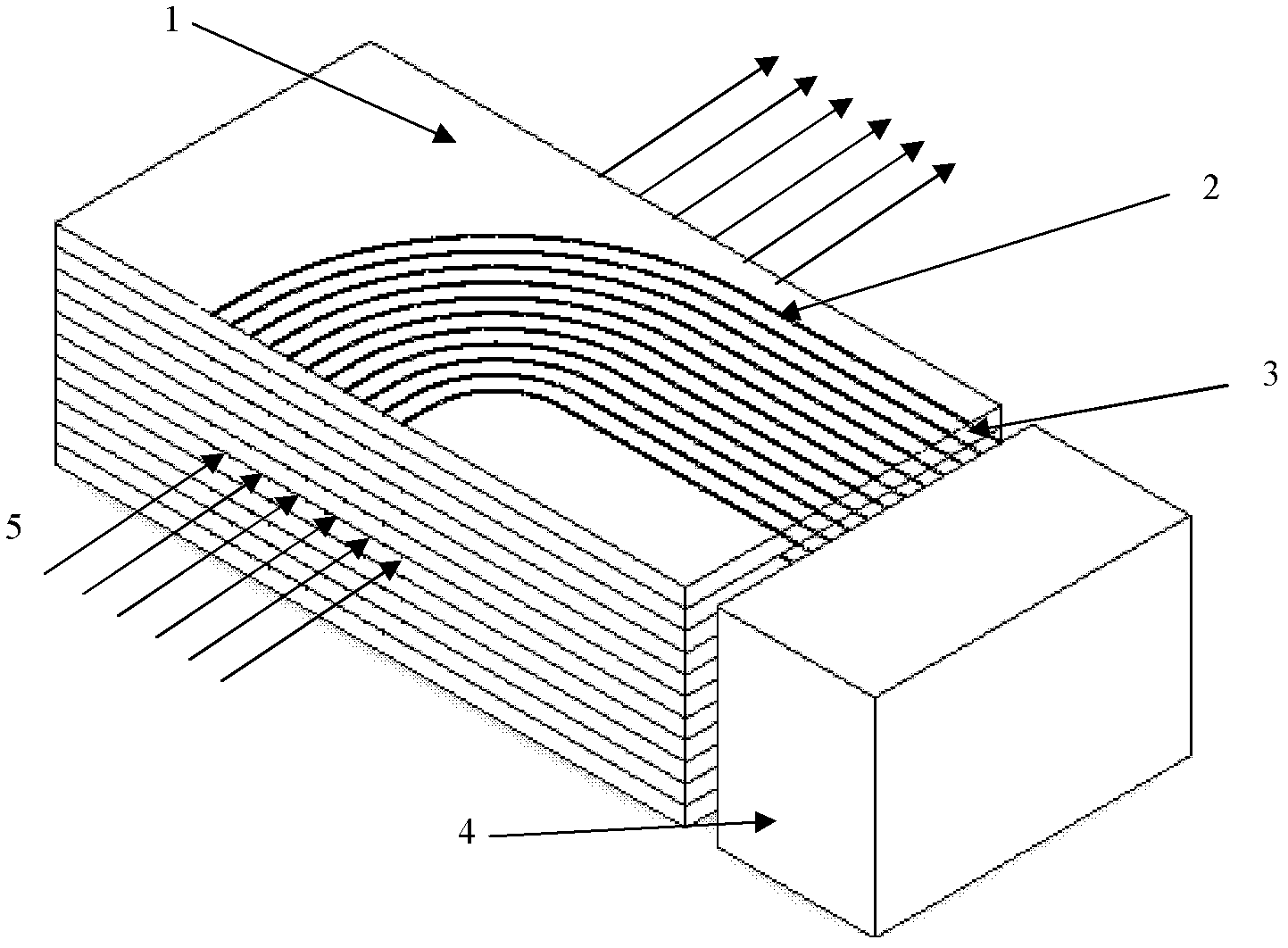

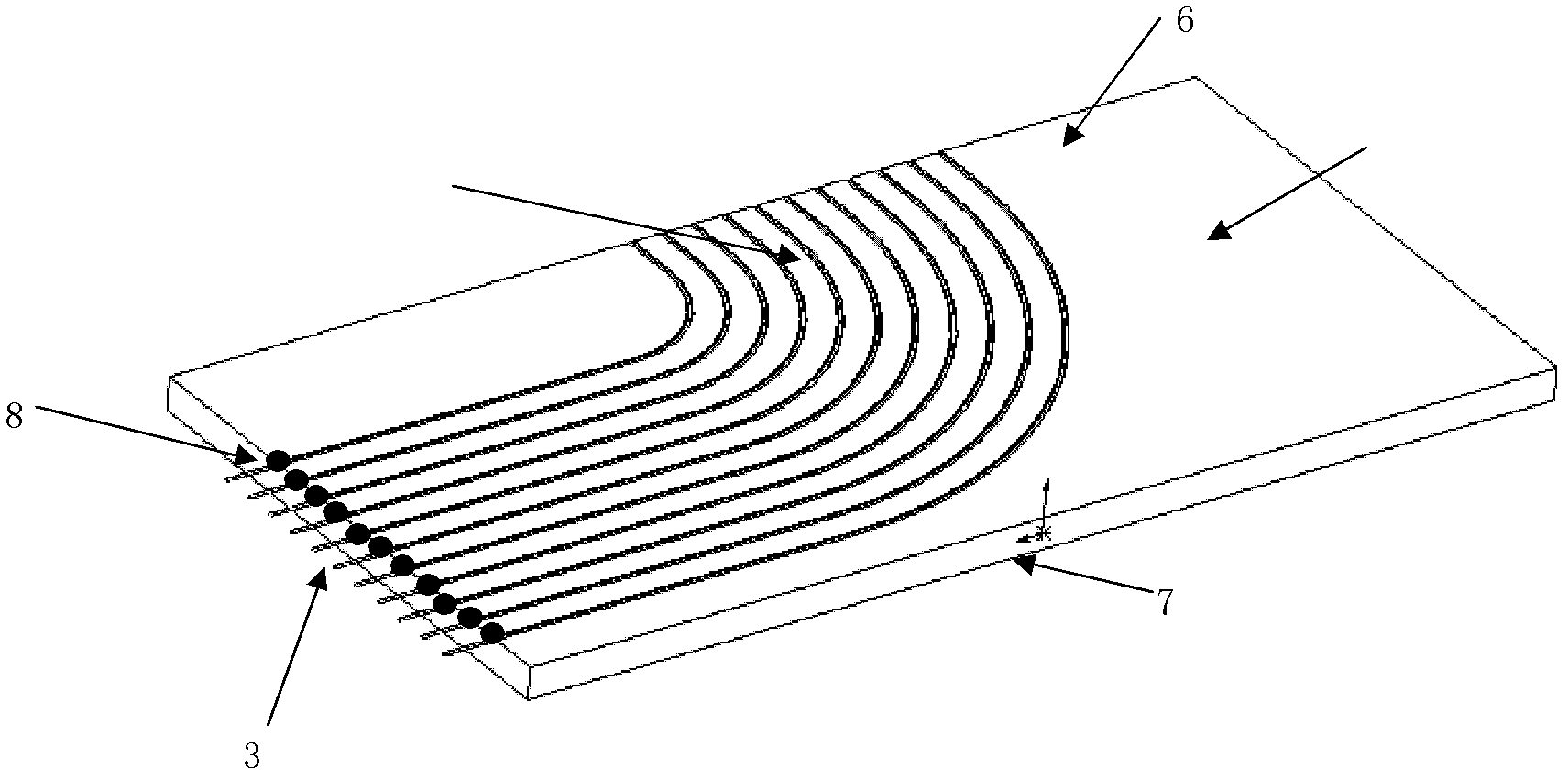

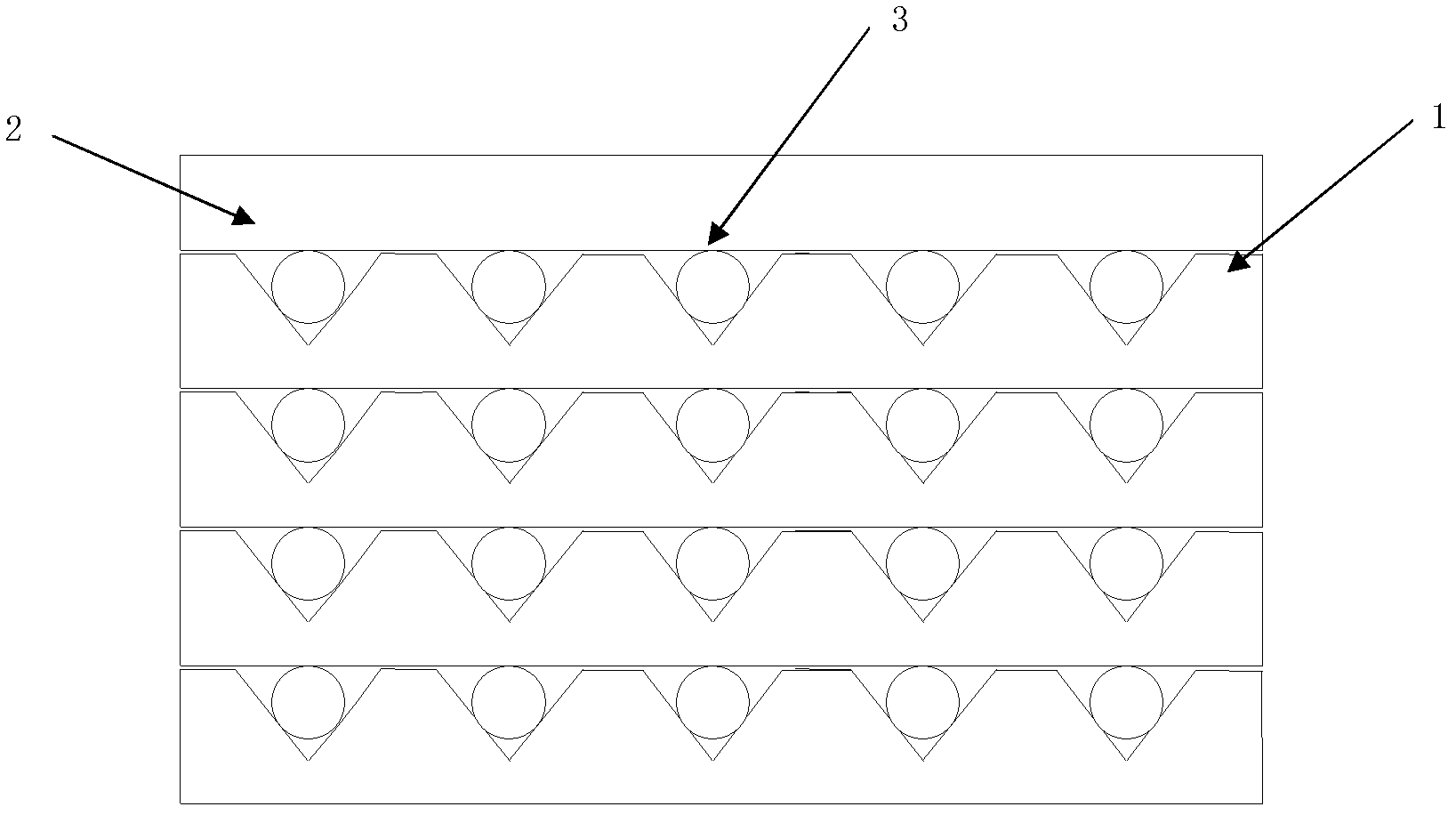

[0028] Such as figure 1 As shown, the high-power laser beam sampler includes a plurality of sampling optical fibers 3 and a plurality of dielectric plates 1 arranged in parallel and stacked along the incident direction of the laser light. One surface of the dielectric plate 1 is a scoring surface 6. First, each surface of the plate is After polishing, the size of the L-shaped groove 2 is designed according to the size of the optical fiber 3, and the L-shaped groove is carved on the flat polishing surface. The cross-section in the L-shaped groove can be V-shaped, U-shaped or other shapes, L One side of the L-shaped groove is in the same direction as the incident laser beam, and the other side is perpendicular to the incident direction of the laser beam. There is a circular arc transition between the two sides. The distance between the L-shaped groove and the circular arc transition fillet depends on the space to be achieved by the sampler. The resolution depends on the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com