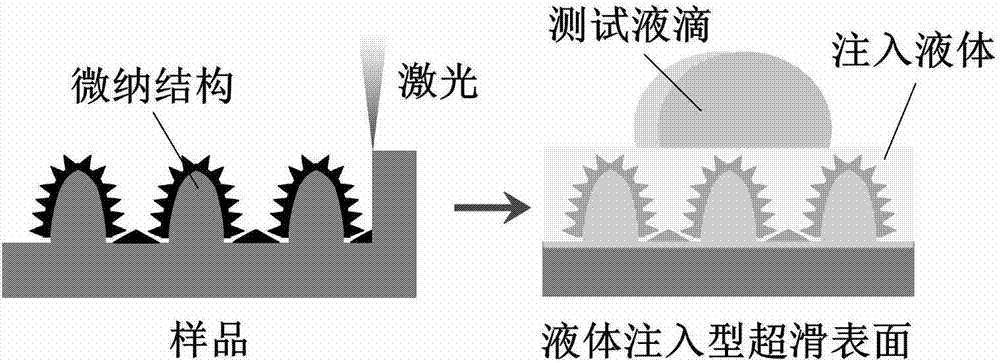

Liquid injection type super smooth surface and laser precision micro-fabrication method thereof

A technology of liquid injection and micromachining, applied in the direction of producing decorative surface effects, microstructure technology, microstructure devices, etc., can solve the problem of destroying surface micro-nano structure, loss of super-hydrophobic performance, failure of super-hydrophobic state, etc. problems, to achieve the effect of easy operation of the process, excellent anti-sticking and super-slip properties, no toxic side effects and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The steps of the liquid injection type stainless steel ultra-smooth surface laser precision micromachining method are as follows:

[0040] Step 1: Use 400 mesh, 1200 mesh and 2000 mesh sandpaper to polish the stainless steel surface in sequence to make it smooth and remove the oxide film;

[0041] Step 2: Clean the surface of the stainless steel in an ultrasonic cleaner filled with absolute ethanol and deionized water in sequence for 10 minutes respectively. The ultrasonic frequency is 20-40KHz and the power range is 100-150W. After cleaning, blow dry the stainless steel surface with cold wind or dry naturally at room temperature to obtain a clean stainless steel surface;

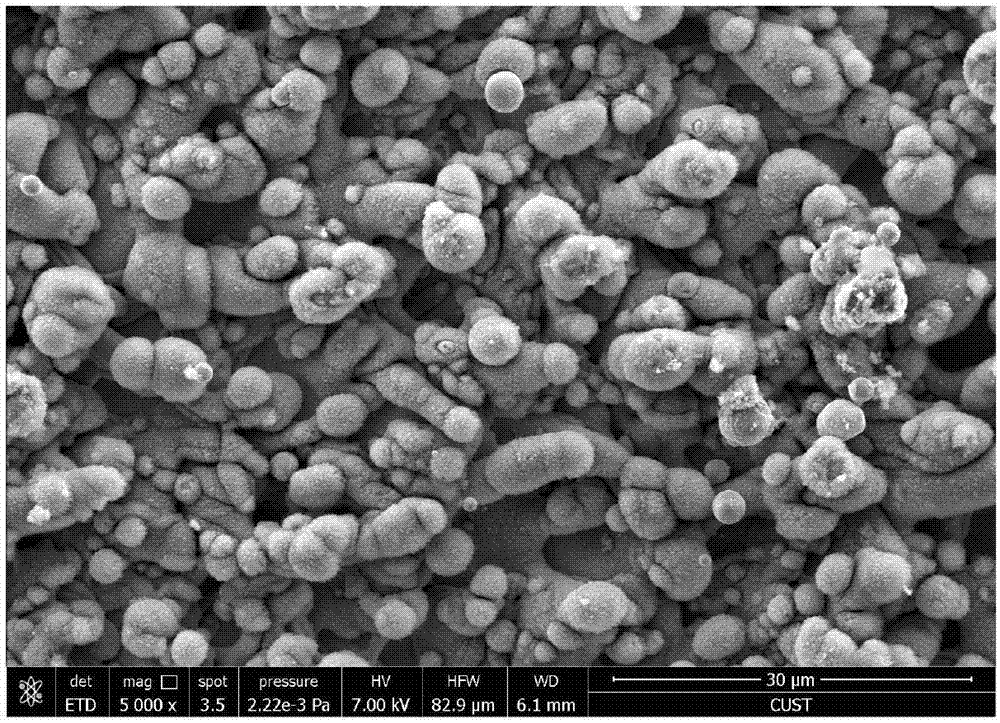

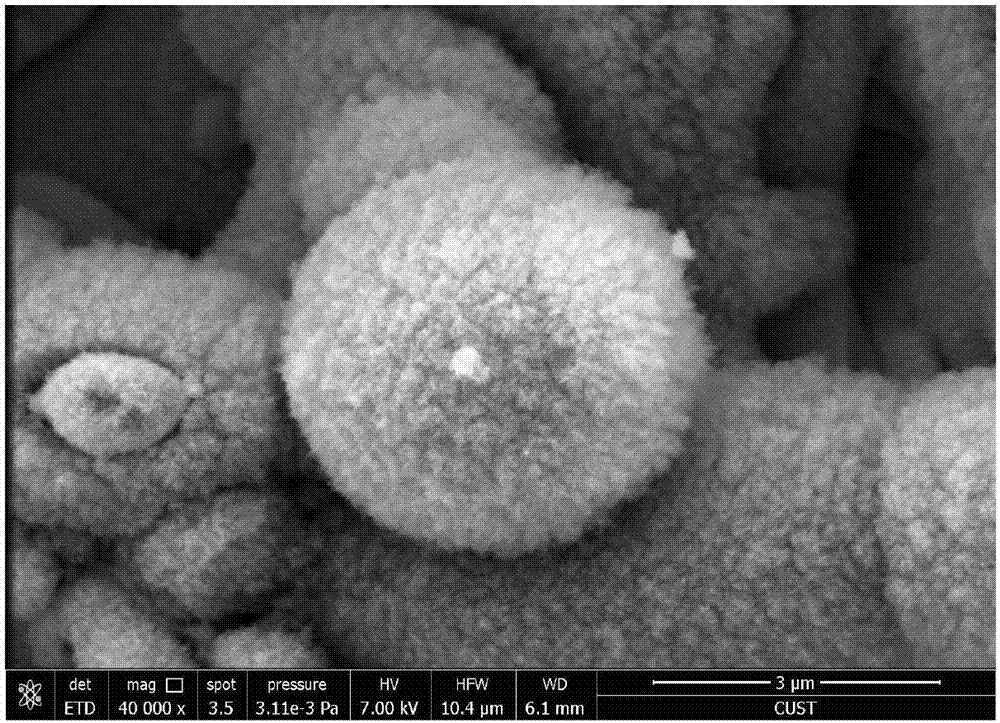

[0042] Step 3: Using laser processing technology, the clean stainless steel sample obtained in step 1 is scanned by using a laser beam with a wavelength of 570-1064nm, and the average power is less than 300W; the scanning range, scanning trajectory and processing speed of the laser are controlled by ...

Embodiment 2

[0046] The steps of the laser precision micromachining method of liquid injection type aluminum alloy super-smooth surface are as follows:

[0047] Step 1: Use 400-mesh, 1200-mesh and 2000-mesh sandpaper in sequence to polish the surface of the aluminum alloy to make it smooth and remove the oxide film;

[0048] Step 2: Clean the surface of the aluminum alloy in an ultrasonic cleaner filled with anhydrous ethanol and deionized water in sequence for 10 minutes respectively, with an ultrasonic frequency of 20-40KHz and a power range of 100-150W. After cleaning, blow dry the aluminum alloy surface with cold wind or dry naturally at room temperature to obtain a clean aluminum alloy surface;

[0049] Step 3: Using laser processing technology, the clean aluminum alloy sample obtained in step 1 is scanned by laser beams with a wavelength of 570-1064nm, and the average power is less than 300W; the scanning range, scanning trajectory and processing speed of the laser are all controlled...

Embodiment 3

[0053] The steps of liquid injection type brass ultra-smooth surface laser precision micromachining method are as follows:

[0054] Step 1: Use 400 mesh, 1200 mesh and 2000 mesh sandpaper to polish the brass surface in order to make it smooth and remove the oxide film;

[0055] Step 2: Clean the surface of the brass in an ultrasonic cleaner filled with absolute ethanol and deionized water in sequence for 10 minutes respectively. The ultrasonic frequency is 20-40KHz and the power range is 100-150W. After cleaning, the brass surface is blown dry with cold wind or air-dried at room temperature to obtain a clean brass surface;

[0056] Step 3: Using laser processing technology, laser beams with a wavelength of 570-1064nm are used to perform laser scanning processing on the clean brass sample obtained in step 1, with an average power of less than 300W; the scanning range, scanning trajectory and processing speed of the laser are all controlled by the computer. Program control and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com