Bilayer structure TC4-base titanium alloy self-lubricating material and preparation method thereof

A technology of self-lubricating materials and double-layer structure, which is applied in the direction of additive manufacturing, process efficiency improvement, and energy efficiency improvement. Uniformity of organizational structure and other issues, to achieve the effect of easy control of process parameters, saving dosage, stable and excellent tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A double-layer structure TC4-based titanium alloy self-lubricating material, including the top layer and the bottom layer structure, both use TC4 titanium alloy as the matrix, and use graphene as the lubricating phase and reinforcing phase, and undergo vibration mixing, high-temperature melting, and vacuum in sequence. TC4-based titanium alloy self-lubricating materials with different additions of graphene on the top and bottom layers were prepared by atomization and laser fusion deposition processes. Among them, the mass ratio of elements Al, V, Fe, C and Ti in TC4 titanium alloy is 6.0:4.0:0.3:0.1:89.6; the thickness of the top layer structure is 1.5mm, and the amount of graphene added is 1.5% of the mass of the base TC4 titanium alloy. wt.%; the thickness of the underlying structure is 6.5mm, and the amount of graphene added is 0.5wt.% of the mass of the matrix TC4 titanium alloy.

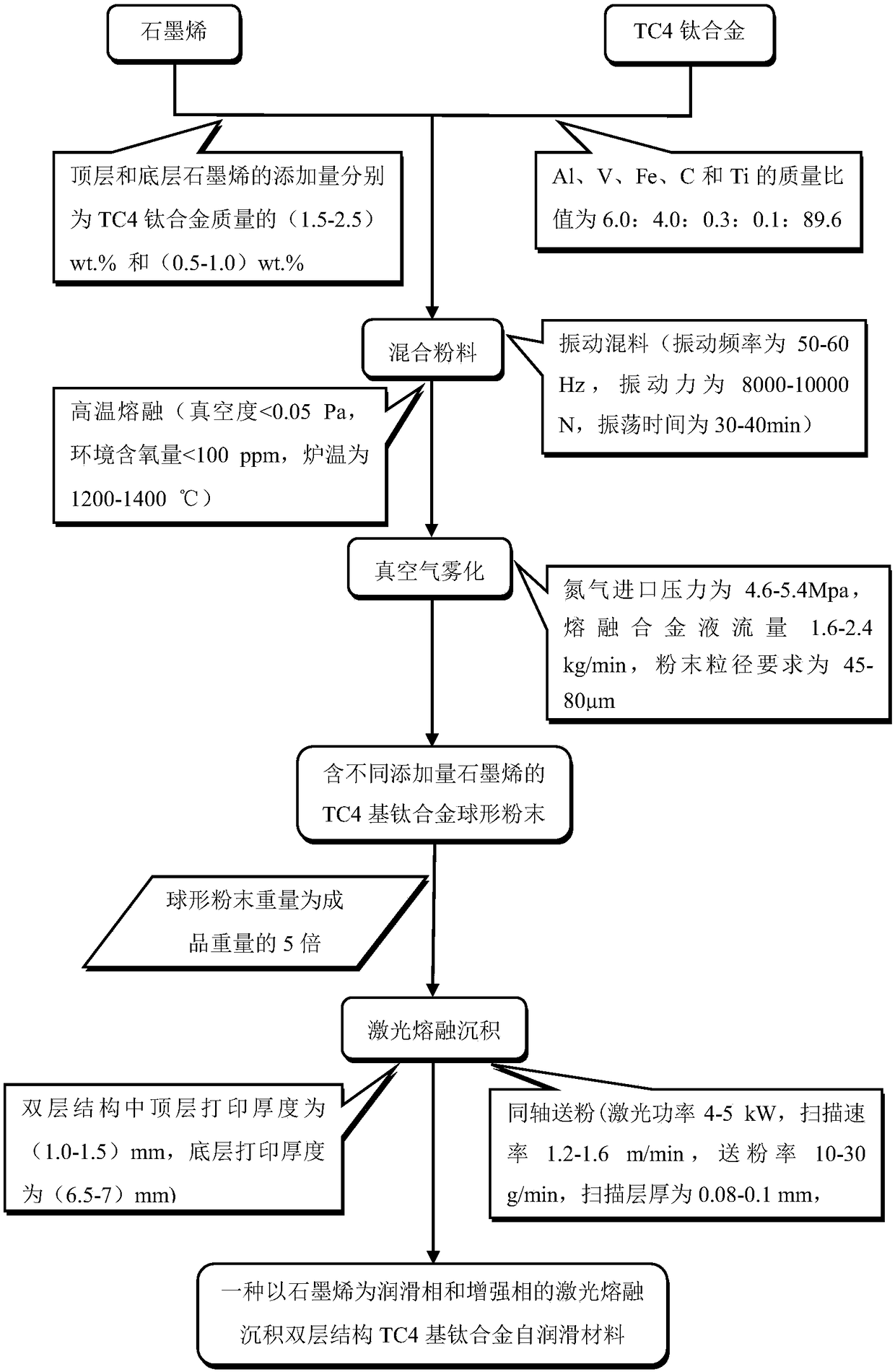

[0038] Such as figure 1 As shown, the above-mentioned preparation method of the doub...

Embodiment 2

[0050] A double-layer structure TC4-based titanium alloy self-lubricating material with graphene as the lubricating phase and reinforcing phase, including a top layer and a bottom layer structure, both of which use TC4 titanium alloy as the matrix, and graphene as the lubricating phase and reinforcing phase; the top layer And the bottom layer is a TC4-based titanium alloy self-lubricating material containing different amounts of graphene. Among them, the mass ratio of elements Al, V, Fe, C and Ti in the TC4 titanium alloy is 6.0:4.0:0.3:0.1:89.6; the thickness of the top layer structure is 1.25mm, and the amount of graphene added is 2.0wt of the mass of the base TC4 titanium alloy .%; the thickness of the underlying structure is 6.75mm, and the amount of graphene added is 0.75wt.% of the mass of the matrix TC4 titanium alloy.

[0051] Such as figure 1 As shown, the above-mentioned preparation method of the double-layer structure TC4-based titanium alloy self-lubricating mater...

Embodiment 3

[0062]A double-layer structure TC4-based titanium alloy self-lubricating material with graphene as the lubricating phase and reinforcing phase, including a top layer and a bottom layer structure, both of which use TC4 titanium alloy as the matrix, and graphene as the lubricating phase and reinforcing phase; the top layer And the bottom layer is a TC4-based titanium alloy self-lubricating material containing different amounts of graphene. Among them, the mass ratio of the elements Al, V, Fe, C and Ti in the TC4 titanium alloy is 6.0:4.0:0.3:0.1:89.6; the thickness of the top layer structure is 1.0mm, and the amount of graphene added is 2.5% of the mass of the base TC4 titanium alloy. wt.%; the thickness of the underlying structure is 7.0mm, and the added amount of graphene is 1.0wt.% of the mass of the matrix TC4 titanium alloy.

[0063] Such as figure 1 As shown, the above-mentioned preparation method of the double-layer structure TC4-based titanium alloy self-lubricating mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com