Oxidized graphene-modified super-hydrophilic super-oleophobic oil-water separation film and preparation method and application thereof

A technology of graphene modification and super oleophobic oil, which is applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of poor water resistance of the omentum, achieve large water flux, no secondary pollution, and speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

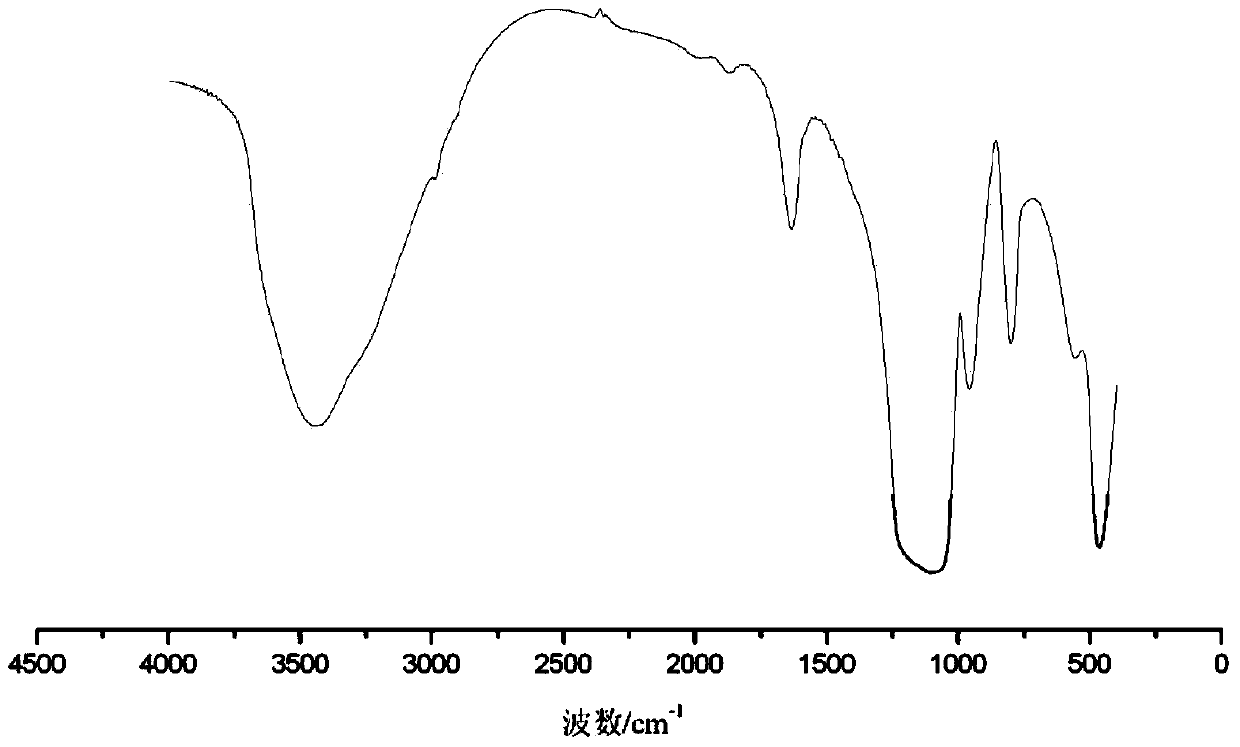

[0032] Example 1: GO modified PVA-PAA / nano-SiO 2 Preparation of stainless steel wire mesh oil-water separation mesh

[0033] (1) Add 230ml of concentrated sulfuric acid into a 1000ml three-neck flask, place it in an ice-water bath, add 10g of primary graphite powder and 5g of sodium nitrate under stirring, and stir for 25min. Add 30g of oxidant potassium permanganate within 30min and react for 1h. Move the flask to a 35°C water bath and continue to stir for 30 minutes, then add 460ml of deionized water to dilute, and the temperature rises to 95°C. After stirring for 15 min, the mixture was transferred to a beaker, diluted to 1 L with deionized water, and 25 ml of 30% H 2 o 2 solution until the color of the reaction solution is golden yellow. Wash 3 times with deionized water, and add 3 drops of HCl solution with a mass concentration of 36.5%. Repeatedly washing the above-mentioned reaction solution with deionized water until pH=6.5, and finally vacuum-filtering the washed...

Embodiment 2

[0042] Example 2: GO modified PEG-PUA / nano-SiO 2 Preparation of Copper Mesh Oil-Water Separation Mesh

[0043] (1) Add 500ml of concentrated sulfuric acid into a 1000ml three-neck flask, place it in an ice-water bath, add 25g of primary graphite powder and 10g of sodium nitrate under stirring, and stir for 25min. Add 60g of oxidant potassium permanganate within 30min and react for 1.5h. Move the flask to a 35°C water bath and continue to stir for 25 minutes, then add 500ml of deionized water to dilute, and the temperature rises to 90°C. After stirring for 15 min, the mixture was transferred into a beaker, diluted to 1.5 L with deionized water, and 50 ml of 30% H 2 o 2 solution until the color of the reaction solution is golden yellow. Wash 5 times with deionized water, and add 5 drops of 35% HCl solution. Wash the above-mentioned reaction solution repeatedly with deionized water until pH=7.5, and finally vacuum filter the washed graphite oxide suspension with a Buchner fu...

Embodiment 3

[0052] Example 3: GO modified PDDA-PAA / nano-SiO 2 Preparation of Aluminum Mesh Oil-Water Separation Mesh

[0053] (1) Add 300ml of concentrated hydrochloric acid to a 1000ml three-neck flask, place it in an ice-water bath, add 15g of primary graphite powder and 7g of sodium nitrate under stirring, and stir for 25min. Add 45g of oxidant potassium chlorate within 30min and react for 1h. Move the flask to a 30°C water bath and continue to stir for 30 minutes, then add 480ml of deionized water to dilute, and the temperature rises to 95°C. After stirring for 15 min, transfer the mixture into a beaker, dilute to 1 L with deionized water, add 30 ml of 30% H 2 o 2 solution until the color of the reaction solution is golden yellow. Wash 4 times with deionized water, and add 3 drops of HCl solution with a mass concentration of 36.5%. Repeatedly washing the above-mentioned reaction solution with deionized water until pH=7.0, and finally vacuum-filtering the washed graphite oxide sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com