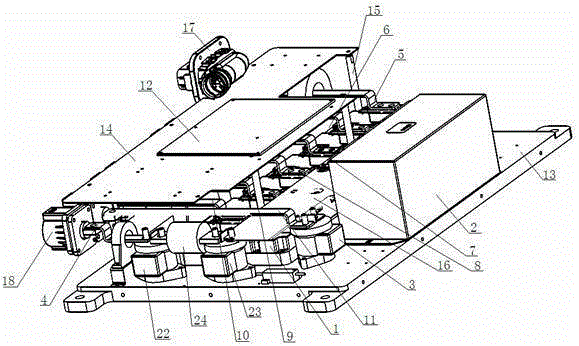

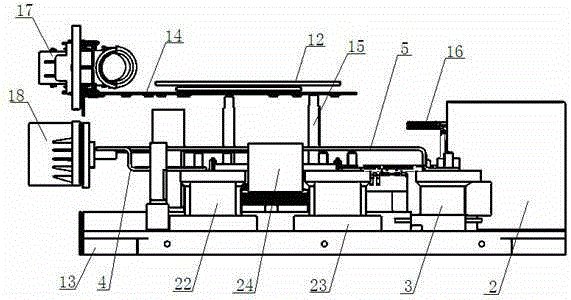

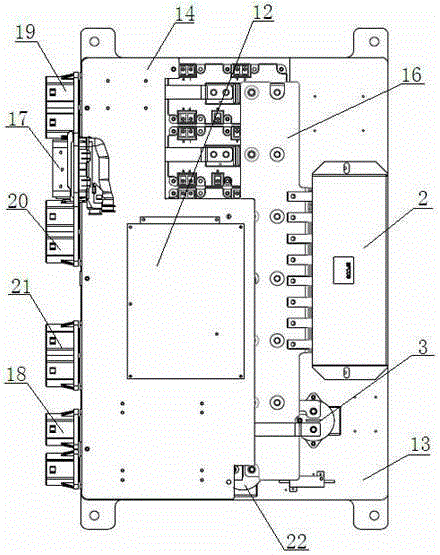

Internal layout structure of switched reluctance machine controller of electric vehicle

A switched reluctance motor, electric vehicle technology, applied in the direction of electronic commutation motor control, control system, electrical components, etc., can solve the problems of lack of compact design, can not meet the requirements of modular design, etc., to achieve compact structure, simple structure , the effect of preventing wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see Figure 1 to Figure 3 , an internal arrangement structure of a switched reluctance motor controller for an electric vehicle, including a high-voltage component, a low-voltage component and a radiator base 13 . The high-voltage components include IGBT module 1, film capacitor 2, high-voltage copper bar and pre-charging contactor 3, and the high-voltage copper bar includes copper bar positive pole 4, copper bar U positive 5, copper bar U negative 6, copper bar V positive 7, copper bar V negative 8, copper bar W positive 9, copper bar W negative 10 and copper bar negative 11. The low-voltage components include a low-voltage main control board 12 and a low-voltage connector 17, and the low-voltage connector 17 is connected to the low-voltage main control board 12 through wires. The high-voltage components are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com