Novel low-resistance injector

A low-resistance syringe, a new type of technology, applied in syringes, infusion sets, etc., can solve problems such as failure to meet industry standards, inability to effectively reduce frictional resistance between the piston and the cylinder wall, and inability to large-scale mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

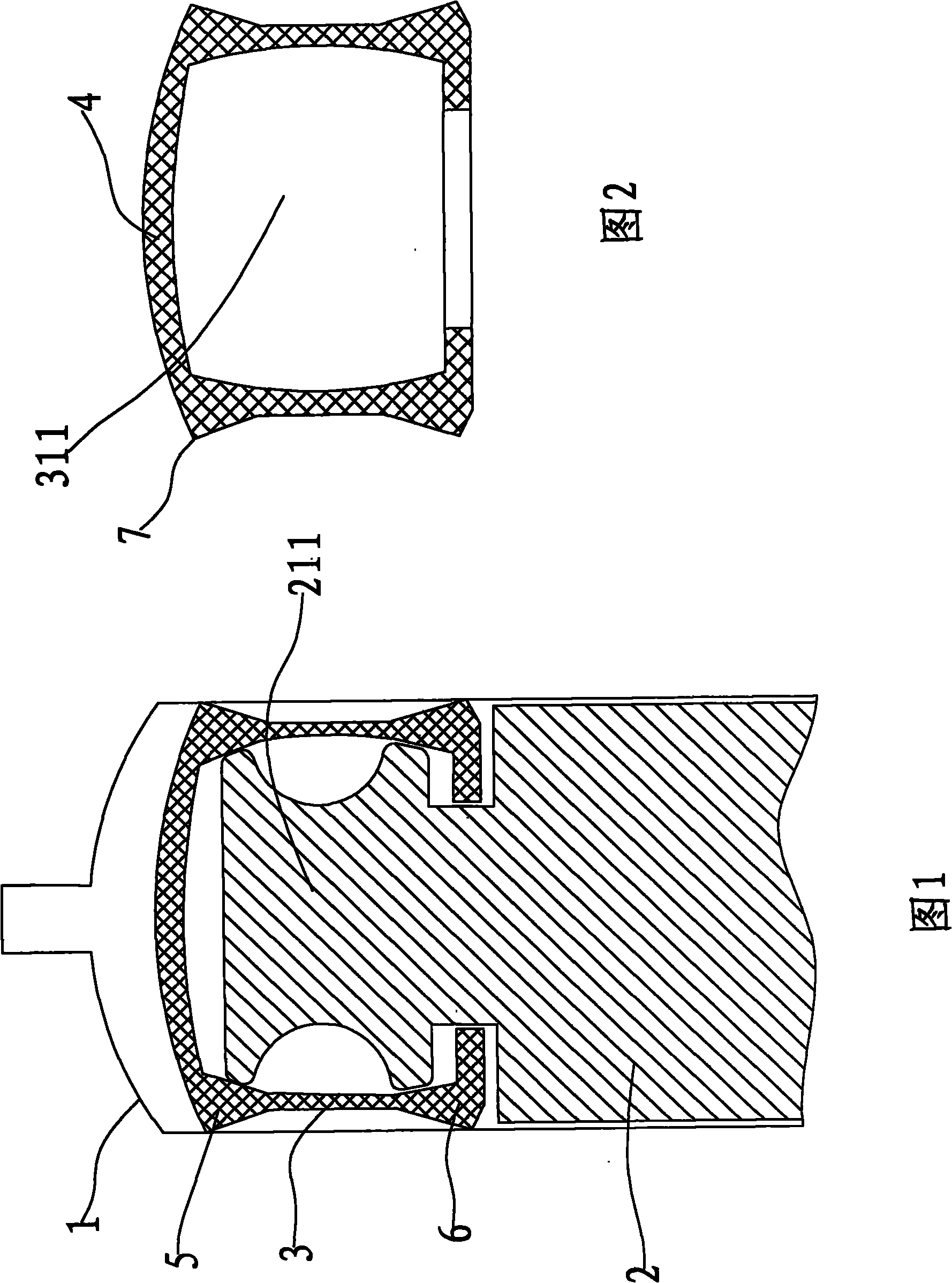

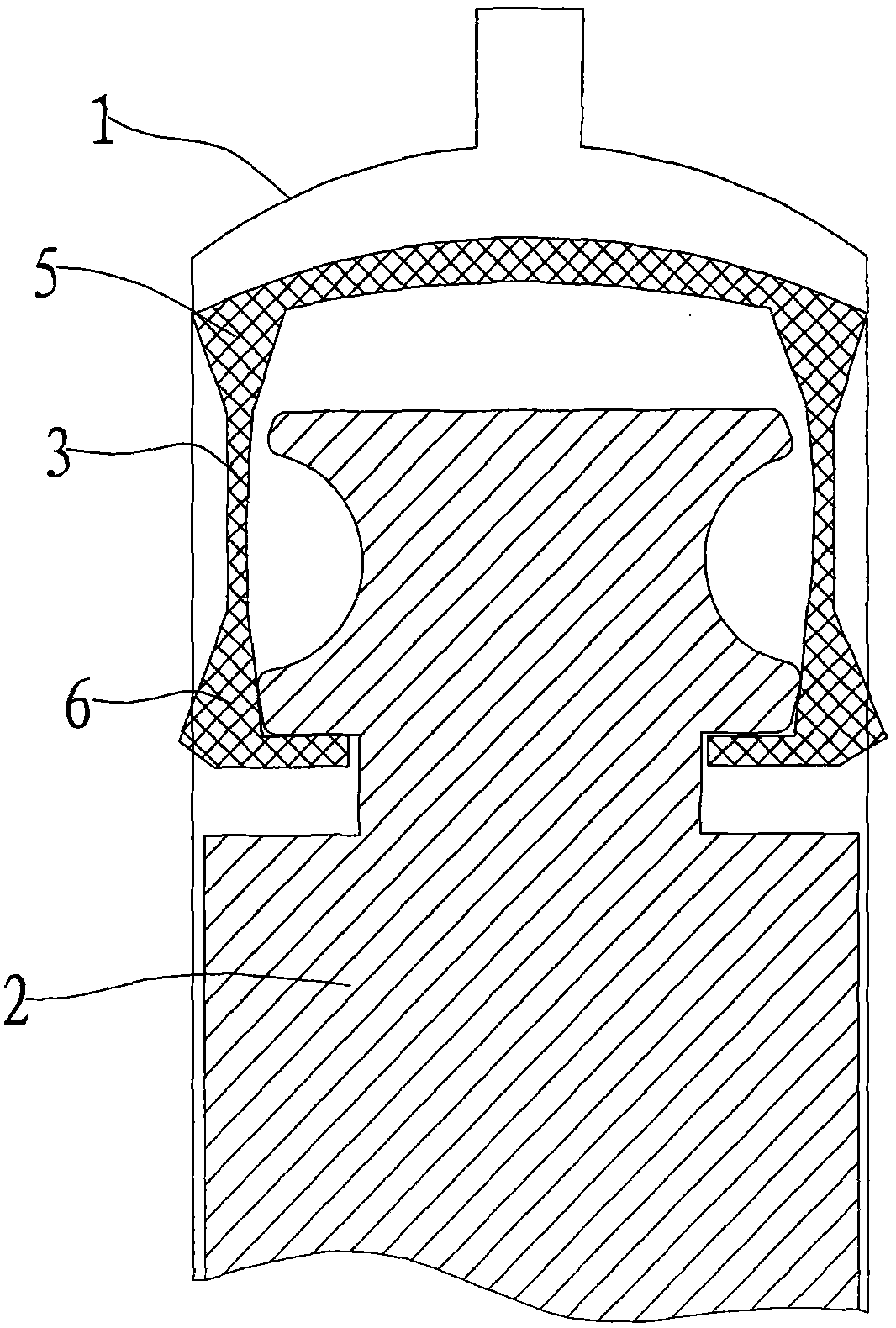

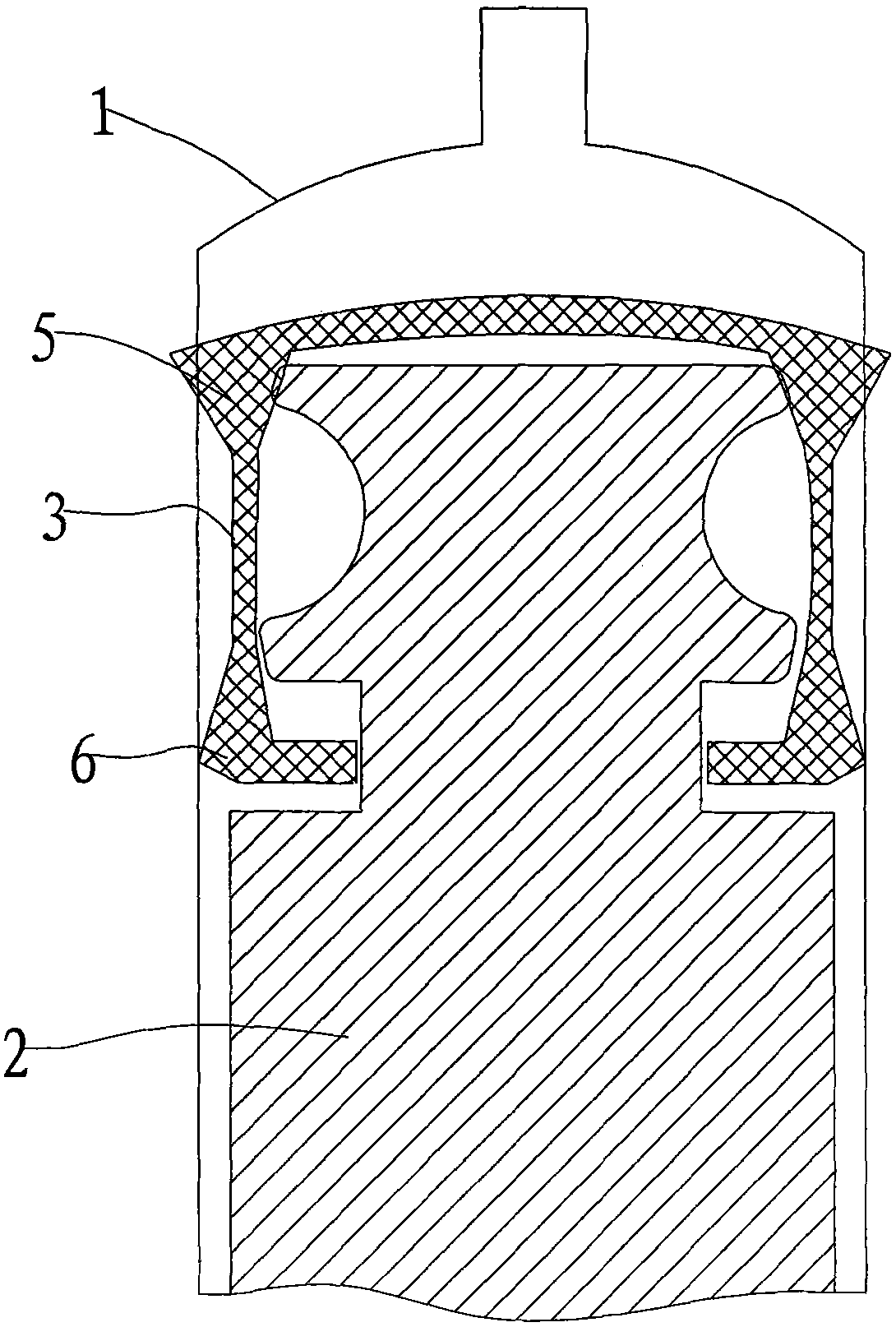

[0017] see figure 1 , a new type of low-resistance syringe, including a syringe (1), a push rod (2), and a rubber stopper (3), the push rod (2) is composed of a body and an installation head (211) for installing the rubber stopper, and the rubber stopper (3) There is a cavity (311) for accommodating the installation head (211). The cavity (311) of the rubber plug (3) is large in the middle and small at both ends along the axial direction of the push rod (2). See figure 2 ,Depend on figure 2 It can be seen that the longitudinal section (along the axial direction of the push rod) of the rubber plug cavity (311) is a waist circle with a large center and a small two ends. The diameter of the upper and lower ends of the installation head (211) is slightly larger than the diameter of the two ends of the cavity (311). Space, the rubber plug (3) can slide back and forth relative to the push rod along the axial direction of the push rod, the height of the rubber plug cavity (311) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com