Green fluorescent carbon quantum dot with high yield and high fluorescent quantum yield, and preparation method thereof

A carbon quantum dot and green fluorescence technology, applied in the field of green fluorescent carbon quantum dots and carbon quantum dots, can solve the problems of low yield fluorescence quantum yield, low yield of green fluorescent carbon quantum dots, etc., and reduce the color temperature. , The effect of solving the problem of luminous brightness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 4mL of ethylenediamine to 0.4g of 2,7-dihydroxynaphthalene, and then add 2mL of 30wt% hydrogen peroxide. At this time, a violent reaction occurs, and a large amount of heat is released while bubbling. After the reaction, 40 mL of absolute ethanol was added and stirred to obtain a uniform deep wine red solution.

[0031] The solution was transferred to a 100mL polytetrafluoroethylene stainless steel autoclave, heated to 180°C for solvothermal reaction for 12h. After the reaction was completed, it was naturally cooled to room temperature to obtain a green fluorescent carbon quantum dot reaction solution.

[0032] Transfer the above-mentioned green fluorescent carbon quantum dot reaction solution to a spinner bottle, place it on a rotary evaporator, concentrate it by rotary evaporator to a small amount of liquid residue, add a small amount of ethyl acetate, centrifuge at 8000rpm for 5min, repeat 3 times, and put it in an oven Dry to obtain purified green fluorescent c...

Embodiment 2

[0043] Add 2mL of ethylenediamine to 0.4g of 2,7-dihydroxynaphthalene, and then add 2mL of 30wt% hydrogen peroxide. At this time, a violent reaction occurs, and a large amount of heat is released while bubbling. After the reaction, 40 mL of absolute ethanol was added and stirred to obtain a uniform deep wine red solution.

[0044] The solution was transferred to a 100mL polytetrafluoroethylene stainless steel autoclave, heated to 180°C for solvothermal reaction for 12h. After the reaction was completed, it was naturally cooled to room temperature to obtain a green fluorescent carbon quantum dot reaction solution.

[0045] Transfer the above-mentioned green fluorescent carbon quantum dot reaction solution to a spinner bottle, place it on a rotary evaporator, concentrate it by rotary evaporator to a small amount of liquid residue, add a small amount of ethyl acetate, centrifuge at 8000rpm for 5min, repeat 3 times, and put it in an oven Dry to obtain purified green fluorescent c...

Embodiment 3

[0048] Add 4mL of ethylenediamine to 0.4g of 2,7-dihydroxynaphthalene, and then add 2mL of 30wt% hydrogen peroxide. At this time, a violent reaction occurs, and a large amount of heat is released while bubbling. After the reaction, 40 mL of absolute ethanol was added and stirred to obtain a uniform deep wine red solution.

[0049] The solution was transferred to a 100mL polytetrafluoroethylene stainless steel autoclave, heated to 200°C for solvothermal reaction for 12h. After the reaction was completed, it was naturally cooled to room temperature to obtain a green fluorescent carbon quantum dot reaction solution.

[0050] Transfer the above-mentioned green fluorescent carbon quantum dot reaction solution to a spinner bottle, place it on a rotary evaporator, concentrate it by rotary evaporator to a small amount of liquid residue, add a small amount of ethyl acetate, centrifuge at 8000rpm for 5min, repeat 3 times, and put it in an oven Dry to obtain purified green fluorescent c...

PUM

| Property | Measurement | Unit |

|---|---|---|

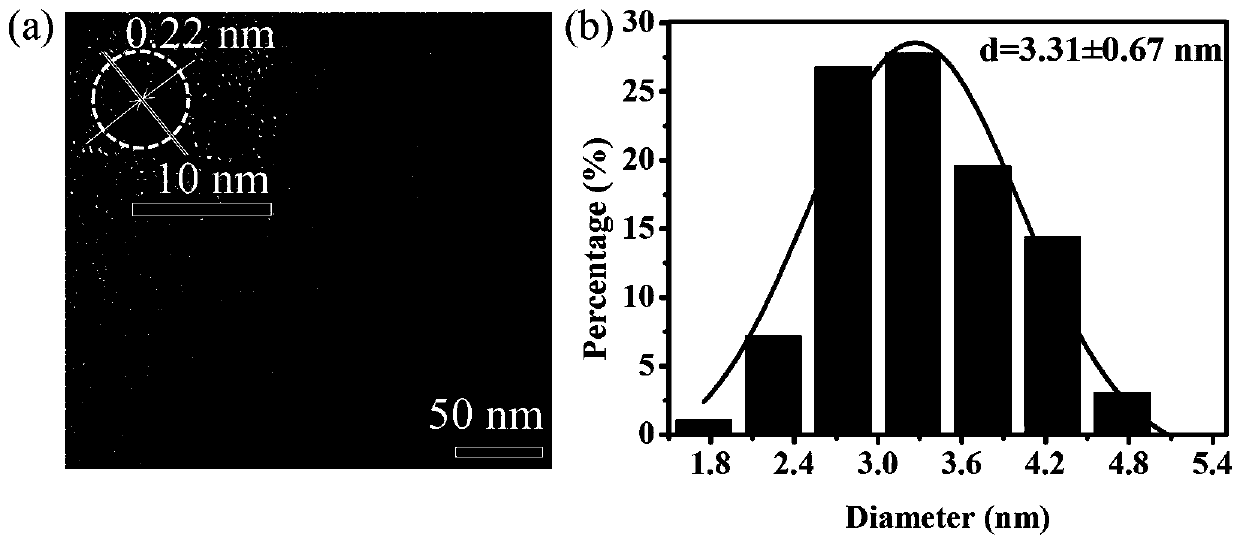

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com