Emulsifier for low-solid-content waterborne epoxy resin coating and preparation method thereof

A water-based epoxy resin and emulsifier technology, used in the field of coating materials, can solve the problems of long emulsification time and complex emulsification process, and achieve the effects of short emulsification time, simple emulsification process and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

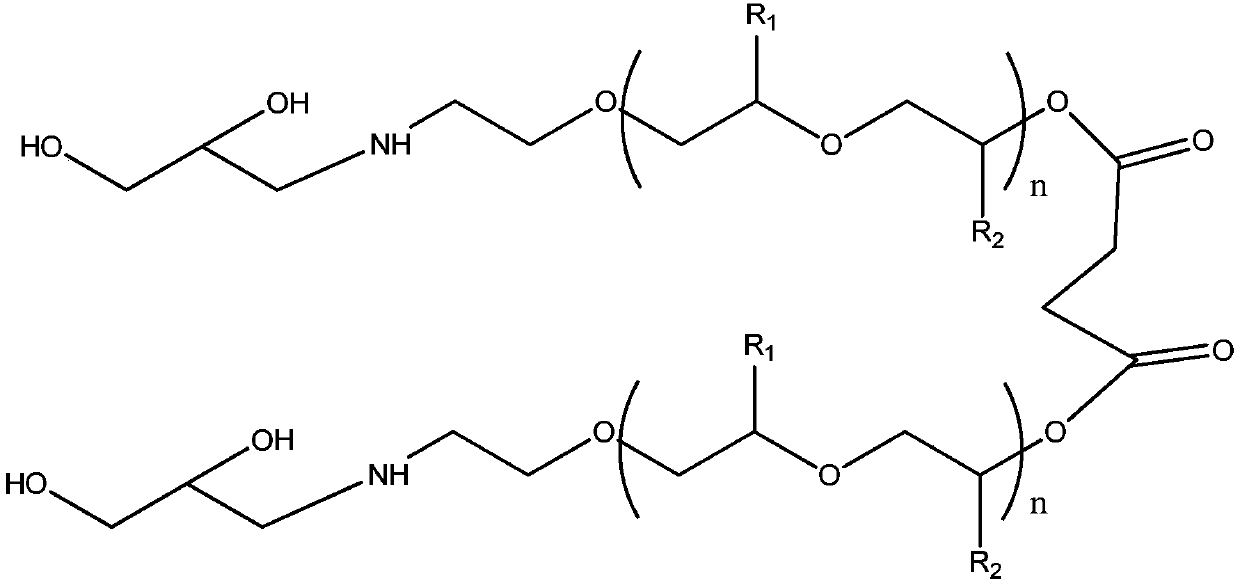

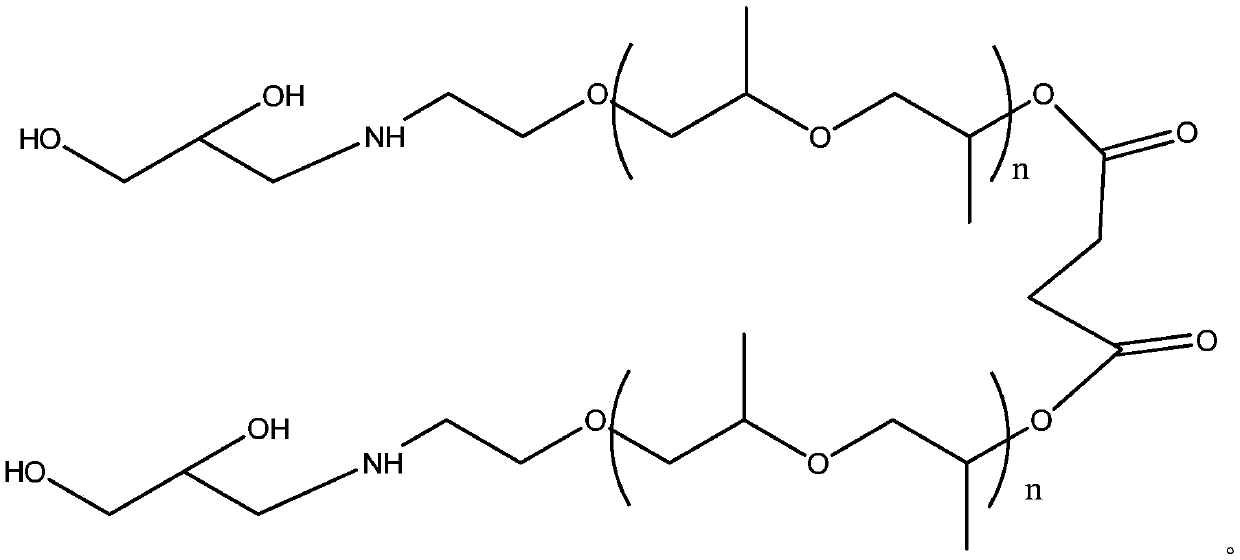

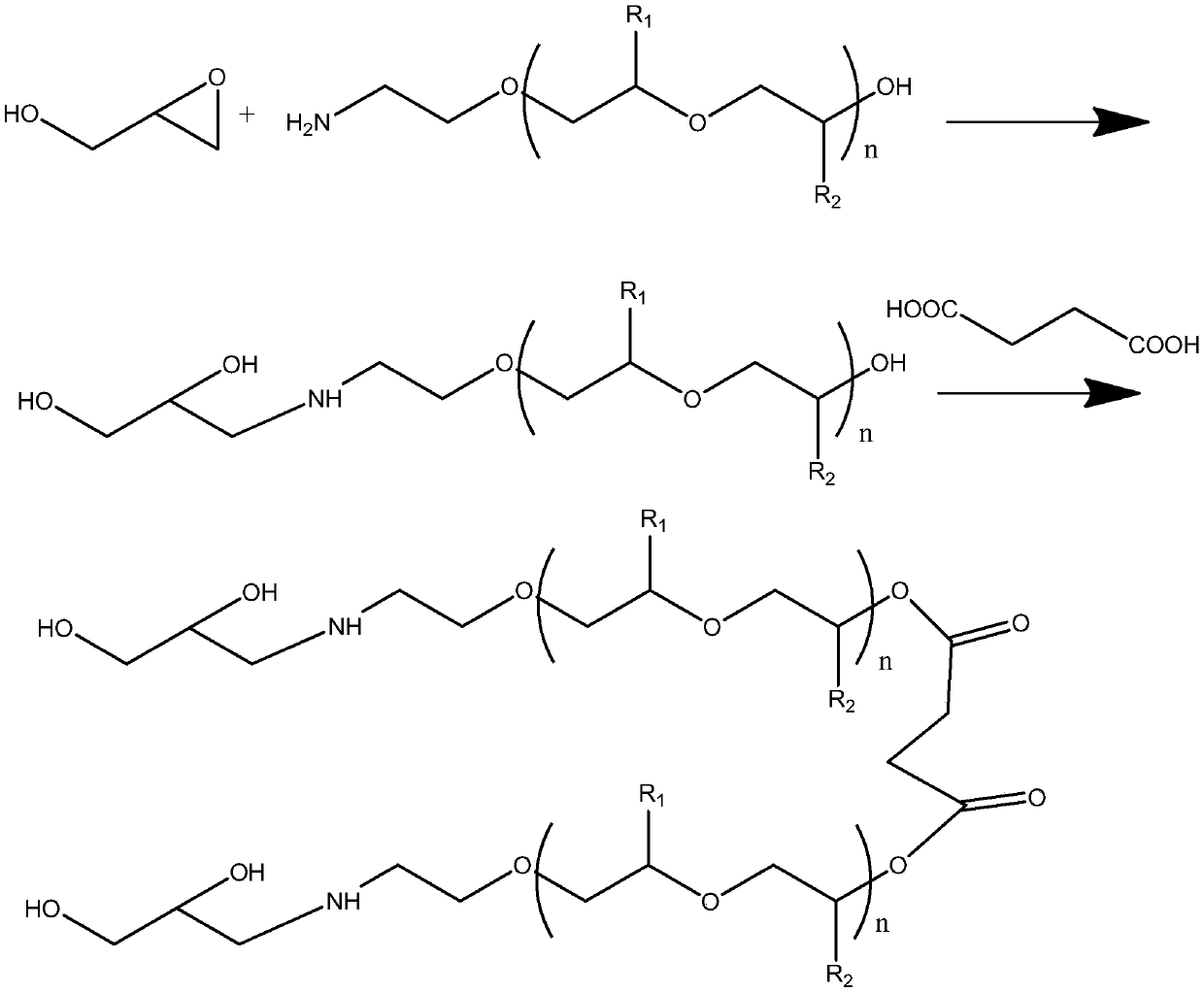

[0035] The preparation method of emulsifier for water-based epoxy resin comprises the following steps:

[0036] (1) At 95°C, the compound shown in formula (I) reacts with glycidyl alcohol under reflux to obtain the compound shown in formula (II); the reaction time is 1.5h, the compound shown in formula (I) reacts with epoxy The dosage ratio of propanol is 1:2.5.

[0037] (2) Cool down to 45°C, add succinic acid to the compound represented by formula (II), and stir to obtain it; the reaction time is 0.5h.

Embodiment 2

[0039] The preparation method of emulsifier for water-based epoxy resin comprises the following steps:

[0040] (1) At 90°C, the compound shown in formula (I) reacted with glycidyl alcohol to obtain the compound shown in formula (II); the reaction time was 2h, and the compound shown in formula (I) reacted with glycidyl alcohol The dosage ratio of alcohol is 1:3.

[0041] (2) Cool down to 40°C, add succinic acid to the compound represented by formula (II), and stir to obtain it; the reaction time is 0.6h.

Embodiment 3

[0043] The preparation method of emulsifier for water-based epoxy resin comprises the following steps:

[0044] (1) At 100°C, the compound shown in formula (I) reacts with glycidyl alcohol under reflux to obtain the compound shown in formula (II); the reaction time is 1h, the compound shown in formula (I) reacts with glycidyl alcohol The dosage ratio of alcohol is 1:2.

[0045] (2) Cool down to 50°C, add succinic acid to the compound represented by formula (II), and stir to obtain it; the reaction time is 0.4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com