Stabilizing agent for lime colloid paint

A technology of stabilizer and glue paint, which is applied in the direction of coating, filling slurry, etc., can solve the problems that the content of harmful substances is difficult to meet the requirements of environmental protection, and it is difficult to meet the requirements, and achieve the effect of low cost, good effect and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: a kind of calcium glue paint, by the following pigment, filler of weight part 、 Auxiliary, base material and dispersion medium: 25-35 parts of gray calcium powder, 5-10 parts of titanium dioxide, 10-15 parts of heavy calcium, 5-10 parts of light calcium, 2-5 parts of sodium bentonite, 0.3 parts of defoamer 0.4 parts, 0.4 parts of dispersant, 0.2 parts of wetting agent, 0.1 parts of leveling agent, 0.1 parts of film-forming aid, 0.15-0.35 parts of thickener, 0.2-0.6 parts of stabilizer, 6-12 parts of emulsion, deionized water 1~47 copies.

[0014] The preparation process is as follows: in the pre-dispersion stage, lime calcium powder, titanium dioxide, heavy calcium, light calcium, sodium bentonite, dispersant, wetting agent, defoamer, and deionized water are dispersed and mixed in proportion; then the mixture is passed through sand Grinding; in the dispersion stage, add stabilizers, defoamers, film-forming aids, leveling agents, thickeners, and emulsions ...

Embodiment 2

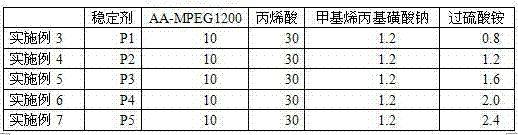

[0021] Embodiment 2: A calcium glue paint stabilizer is prepared from the following components by weight: 19 parts of water, 10 parts of polyethylene glycol 1200 monomethoxyether acrylate, and 30 parts of acrylic acid are made into monomer aqueous solution for later use , make 25 parts of water and 0.5~2.5 parts of ammonium persulfate into an aqueous initiator solution for later use; add 1.2 parts of sodium methallylsulfonate and 18.5 parts of water into the container, raise the temperature to 75~80°C, and start dripping Add monomer aqueous solution and initiator aqueous solution. The monomer aqueous solution is added dropwise in 3 hours, and the initiator aqueous solution is added dropwise in 4 hours. After the dropwise addition, the temperature is raised to 87°C to continue the reaction for 2 hours, and then the temperature is lowered to below 40°C and 30% sodium hydroxide is added. The aqueous solution adjusts the pH to 7-8.

[0022] Polyethylene glycol 1200 monomethoxy eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com