A method of series/parallel adjustable ultrasonic tank demulsification

An ultrasonic and demulsification technology, which is applied in the direction of electric/magnetic dehydration/demulsification, immiscible liquid separation, chemical/physical/physicochemical process of energy application, etc., can solve the problems of electroacoustic efficiency, high manufacturing cost, Problems such as complex equipment structure, to achieve the effect of prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

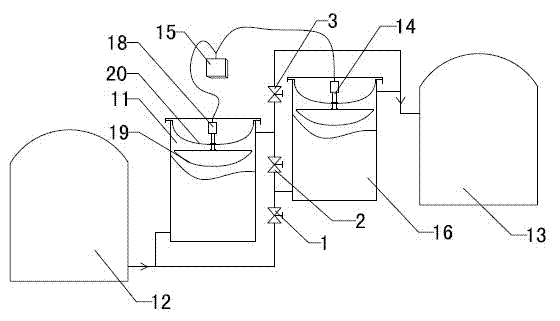

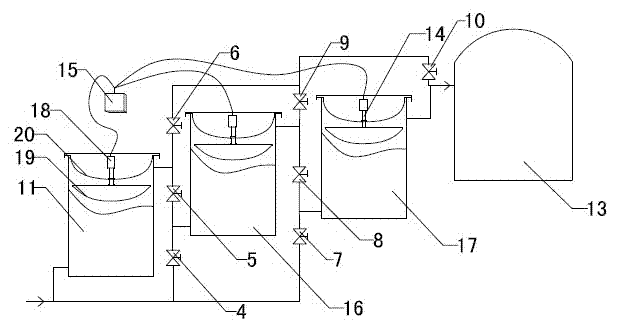

[0042] Such as figure 2 As shown, the ultrasonic demulsification tanks and the sedimentation dehydration tanks 13 are connected by pipelines, and the fourth valve 4, the fifth valve 5, the sixth valve 6, the seventh valve 7, the eighth valve 8, and the fourth valve are arranged between the pipelines. Nine valves 9 and tenth valves 10 are used to adjust the series-parallel relationship between the two ultrasonic demulsification tanks. Close the fifth valve 5 and the eighth valve 8, open the fourth valve 4, the sixth valve 6, the seventh valve 7, the ninth valve 9, and the tenth valve 10, which can realize single-stage parallel operation, suitable for different emulsification degrees Demulsification of oil-water emulsion; open the fifth valve 5, the eighth valve 8, close the fourth valve 4, the sixth valve 6, the seventh valve 7, and the ninth valve 9, which can realize 3-stage series operation, and choose to pass through 3 stages step by step Stage series demulsification, sui...

Embodiment 2

[0045] The device described in Example 1 was used.

[0046] Such as figure 2 As shown, before the crude oil enters the tank, enter the device installed in series / parallel of the above three ultrasonic demulsification tanks, conduct the ultrasonic tank demulsification test of high water content Shengli crude oil, open the fifth valve 5, the eighth valve 8, and close the fourth The valve 4, the sixth valve 6, the seventh valve 7, and the ninth valve 9 realize series operation. The speed of water-containing crude oil through the total feed port is 2m 3 / min. After the tank-type demulsification of three ultrasonic demulsification tanks connected in series with a single set of ultrasonic transducers and distributors, the emulsified waste oil with high water content is subjected to sedimentation and dehydration for 48 hours in the sedimentation dehydration tank. The temperature in the ultrasonic demulsification tank is controlled to be 85°C, the ultrasonic frequency is 160kHz in...

Embodiment 3

[0048] The device described in Example 1 was used.

[0049] Such as figure 2 As shown, before the crude oil enters the tank, it enters the above-mentioned three ultrasonic demulsification tanks installed in series / parallel to perform ultrasonic tank demulsification of high water content Shengli crude oil, close the fifth valve 5 and the eighth valve 8, and open the fourth valve 4. The sixth valve 6, the seventh valve 7, the ninth valve 9, and the tenth valve 10 realize the parallel operation of three ultrasonic demulsification tanks. The speed of water-containing crude oil through the total feed port is 4m 3 / min. After the tank-type demulsification of three ultrasonic demulsification tanks in parallel with a single set of ultrasonic transducers and distributors, the emulsified oil with high water content is subjected to sedimentation and dehydration in the sedimentation dehydration tank for 48 hours. Control the temperature in the ultrasonic demulsification tank to 20°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com