Amino-modified polysiloxane softener and preparation method thereof

A polysiloxane and amino modification technology, applied in the direction of improved hand fibers, textiles and papermaking, fiber treatment, etc., can solve the problems of poor fabric softness, softness decline, poor yellowing resistance, etc., to achieve Improve decontamination performance, prevent demulsification, and stabilize performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

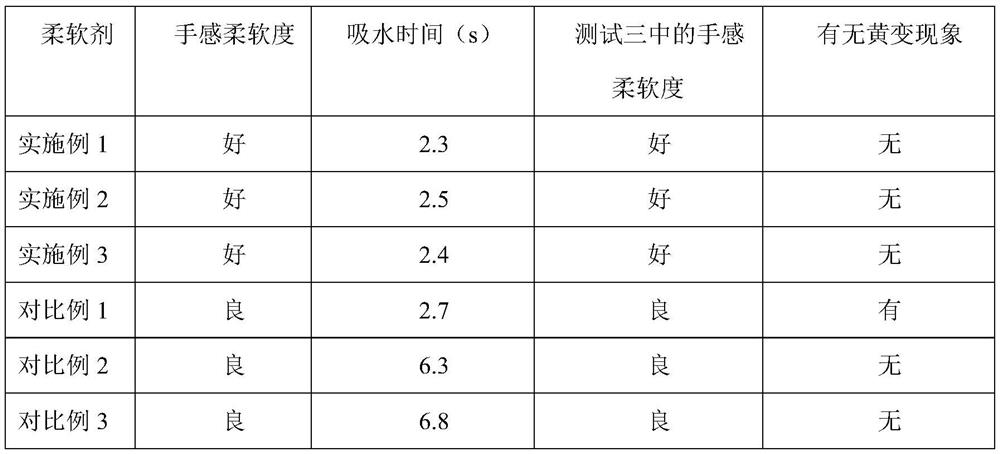

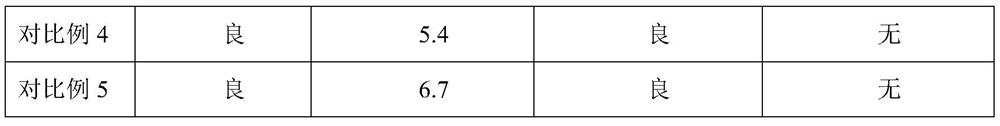

Examples

preparation example Construction

[0027] Preferably, the preparation method of the amino-modified polysiloxane comprises the following steps:

[0028] (1) Infuse nitrogen into the four-necked flask, add γ-chloropropylmethyldimethoxysilane, heat γ-chloropropylmethyldimethoxysilane to 70-80°C, and carry out while heating Stir, then add diethanolamine into the four-necked flask, and react at 70-80°C for 3-5h;

[0029] (2) After step (1), lower the temperature of the compound obtained in (1) to 40-50°C, then add distilled water and hydrolyze for 6-8h, the γ-chloropropylmethyldimethoxysilane , diethanolamine, distilled water mass ratio is 1:2-3:1-3;

[0030] (3) Carrying out the mixture obtained in (2) to remove excess water by vacuum distillation to obtain the liquid mixture;

[0031] (4) Pass nitrogen into the three-necked flask, then add the liquid mixture in (3) into the three-necked flask and start to heat up and stir. After the temperature rises to 60-70°C, add hexamethylcyclotrisiloxane, four Methyl ammon...

Embodiment 1

[0048] An amino-modified polysiloxane softener, in parts by weight, its raw materials include 30 parts of polysiloxane, 10 parts of nonionic surfactant, 5 parts of stabilizer, 5 parts of emulsifier, and 50 parts of water , the emulsifier is a polyether emulsifier, the polyether emulsifier is polyoxyethylene lauryl ether, the CAS number is: 9002-92-0, purchased from Jiangsu Haian Petrochemical Factory. Described polysiloxane is amino-modified polysiloxane, and the preparation method of described amino-modified polysiloxane comprises the following steps:

[0049] (1) Introduce nitrogen into the four-necked flask, add γ-chloropropylmethyldimethoxysilane, heat the γ-chloropropylmethyldimethoxysilane to 70°C, and stir while heating, Then add diethanolamine into the four-necked flask, and react at 70°C for 3 hours. The CAS number of γ-chloropropylmethyldimethoxysilane is: 18171-19-2, purchased from Shanghai Yishi Chemical Co., Ltd. , the CAS number of diethanolamine is: 111-42-2, p...

Embodiment 2

[0060] The difference with Example 1 is: amino-modified polysiloxane softener, by weight, its raw materials include polysiloxane 40 parts, nonionic surfactant 20 parts, stabilizer 6 parts, emulsifying 7 parts of agent, 60 parts of water, and described emulsifier is polyether type emulsifier. Described polysiloxane is amino-modified polysiloxane, and the preparation method of described amino-modified polysiloxane comprises the following steps:

[0061] (1) Infuse nitrogen into the four-necked flask, add γ-chloropropylmethyldimethoxysilane, heat γ-chloropropylmethyldimethoxysilane to 75°C, and stir while heating, Add diethanolamine to the four-necked flask and react at 75°C for 4 hours;

[0062] (2) After step (1) is finished, the temperature of the compound obtained in (1) is lowered to 45° C., and then distilled water is added for hydrolysis for 7 hours. The γ-chloropropylmethyldimethoxysilane, diethanolamine, The mass ratio of distilled water is 1:3:3;

[0063] (3) Carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com