Normal-temperature bi-component or multi-component curing system and application thereof

A two-component, multi-component technology, applied in the polymer field, can solve the problems of poor effect, difficult to use, easy to produce yellowing and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

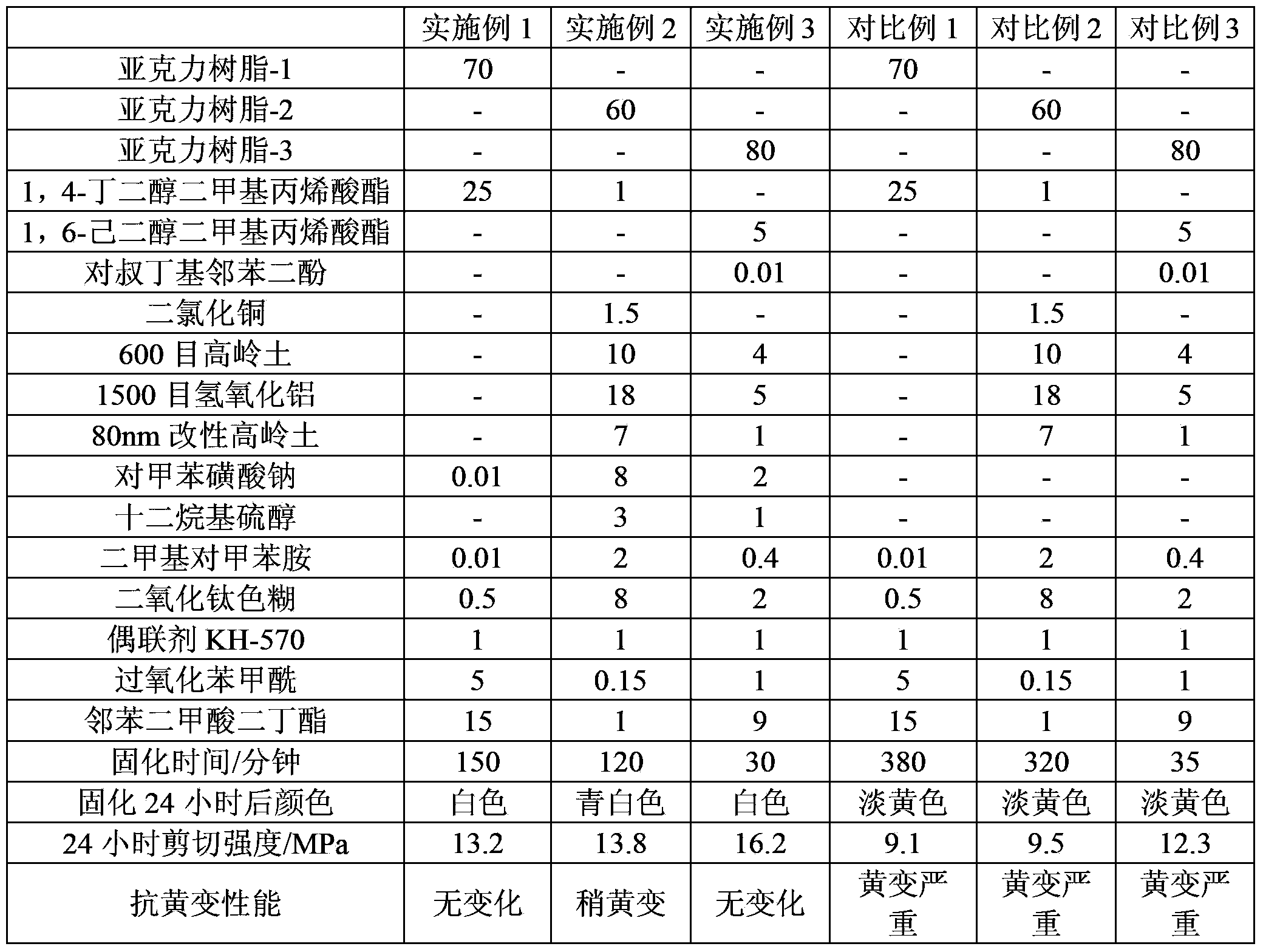

[0119] Acrylic resin-1, 1,4-butanediol dimethacrylate, sodium p-toluenesulfonate, dimethyl-p-toluidine, titanium dioxide color paste, coupling agent KH-570 of the weight parts listed in Table 1 Mix and store as component A, get the benzoyl peroxide and dibutyl phthalate listed in Table 1 and mix and store as component B, when using, mix the first component with the Mix component B evenly, take a small amount and spread it on the lap joint of the two boards, measure the shear strength for 24 hours after curing and polishing, put the rest in a 200ml paper cup, and get the product P1 after curing.

[0120] The obtained product P1 was tested according to the test method for its anti-yellowing performance, curing time, and 24-hour shear strength, and the results are listed in Table 1.

Embodiment 2

[0122] Acrylic resin-2, 1,4-butanediol dimethacrylate, copper dichloride, 600 mesh kaolin, 1500 mesh aluminum hydroxide, 80nm modified kaolin, p-toluenesulfonate in parts by weight listed in Table 1 Sodium peroxide, dimethyl p-toluidine, titanium dioxide color paste, coupling agent KH-570 are mixed and stored as component A, and benzoyl peroxide and dibutyl phthalate listed in table 1 are taken Mix and store as B component, get the dodecylmercaptan listed in Table 1 and store as C component, during application, combine described A component, described B component and described C component Divide and stir evenly, take a small amount and apply it on the lap joint of the two boards, measure the shear strength for 24 hours after curing and polishing, and put the rest in a 200ml paper cup, and obtain the product P2 after curing.

[0123] The resulting product P2 was tested according to the test method for its anti-yellowing performance, curing time, and 24-hour shear strength, and ...

Embodiment 3

[0125] Acrylic resin-3, 1,6-hexanediol dimethacrylate, p-tert-butylcatechol, dimethyl-p-toluidine, titanium dioxide color paste, coupling agent KH- 570 and 600 mesh kaolin, 1500 mesh aluminum hydroxide, 80nm modified kaolin, and sodium p-toluenesulfonate are mixed and stored as component A, and benzoyl peroxide and phthalic acid dicarboxylate listed in Table 1 are taken. The butyl ester is mixed and stored as the B component, and the dodecyl mercaptan listed in Table 1 is stored as the C component. When applying, stir the A component, the B component and the C component evenly, take a small amount and apply it on the lap joint of the two boards, measure the shear strength for 24 hours after curing and polishing, and put the rest in a 200ml paper cup Among them, the product P3 is obtained after curing.

[0126] The resulting product P3 was tested for its anti-yellowing performance, curing time, and 24-hour shear strength according to the test method, and the results are listed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com