Preparation method of hyper-branched polyether amide block silicone

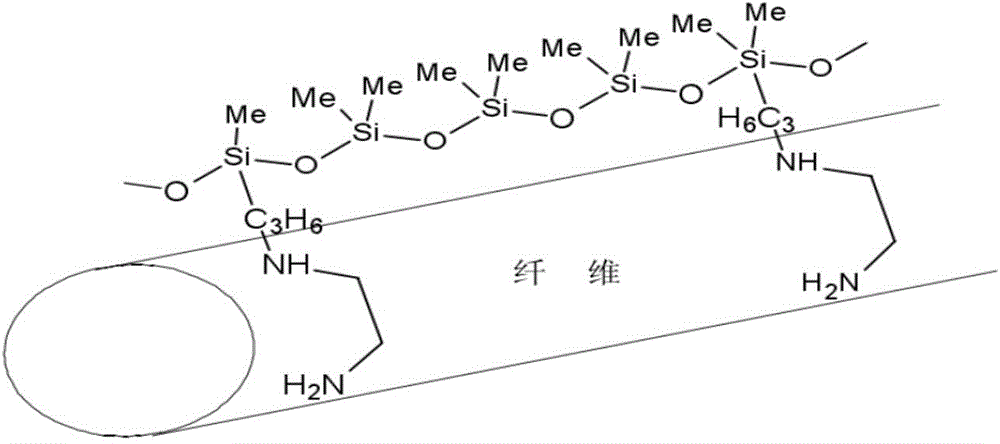

A hyperbranched polyether and silicone technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor washability, softness and smoothness inferior to amino silicone oil, etc., to achieve increased hydrophilicity, good anti-staining, Effects that improve durability and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

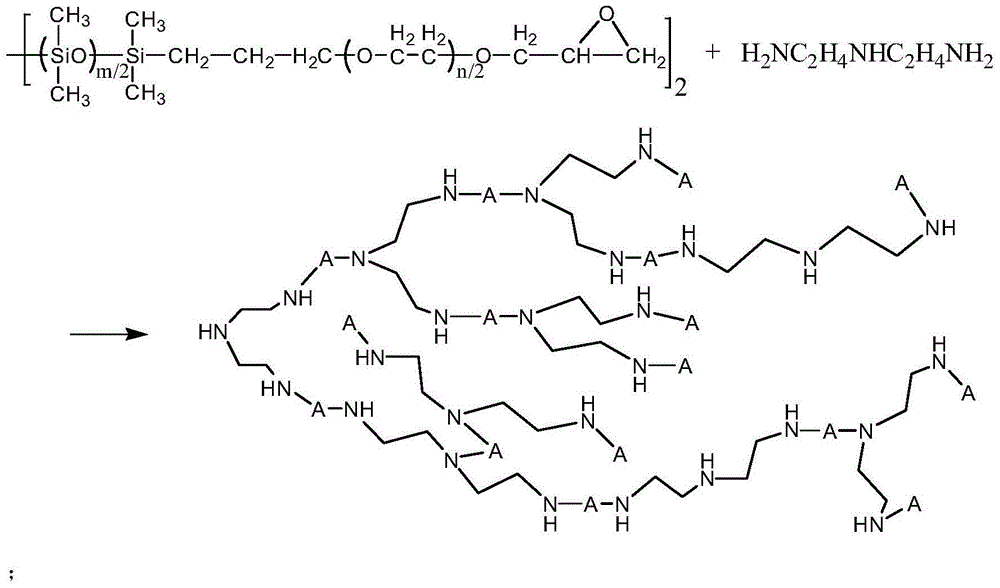

[0027] A preparation method of hyperbranched polyether amino block silicone, comprising the steps of:

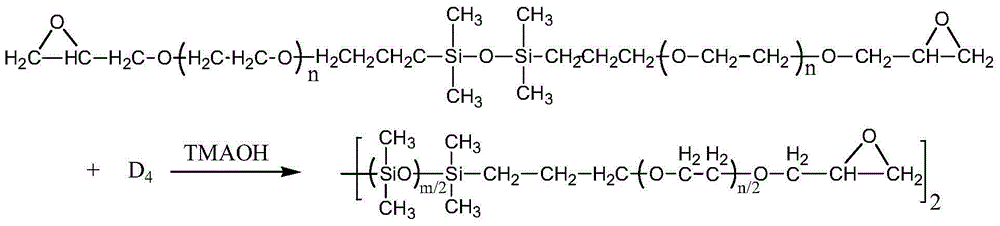

[0028] (1) Preparation of polyether / epoxy block silicone oil:

[0029] Add the prepared end-epoxy head-sealing agent and octamethylcyclotetrasiloxane according to a certain ratio, and add the solvent isopropanol in a three-port reaction kettle with a nitrogen filling device and a reflux condenser, and the dosage is the reactant 30% of the total amount. Stir and heat up to 50°C for dehydration under reduced pressure for 30 minutes, add a certain amount of alkali catalyst, continue to heat up to 100°C, and keep warm for 4 hours; then remove low boilers under reduced pressure to obtain polyether / epoxy block silicone oil.

[0030] The molar ratio of the epoxy-terminated polyether block siloxane to octamethylcyclotetrasiloxane is 1:15.

[0031] The alkali catalyst is tetramethylammonium hydroxide, and the catalyst consumption is 0.035%.

[0032] The epoxy-terminated capping ag...

Embodiment 2

[0037] A preparation method of hyperbranched polyether amino block silicone, comprising the steps of:

[0038] (1) Preparation of polyether / epoxy block silicone oil:

[0039] Add the prepared end-epoxy head-sealing agent and octamethylcyclotetrasiloxane according to a certain ratio, and add the solvent isopropanol in a three-port reaction kettle with a nitrogen filling device and a reflux condenser, and the dosage is the reactant 30% of the total amount. Stir and heat up to 50°C for dehydration under reduced pressure for 30 minutes, add a certain amount of alkali catalyst, continue to heat up to 110°C, and keep warm for 5 hours; then remove low boilers under reduced pressure to obtain polyether / epoxy block silicone oil.

[0040] The molar ratio of the epoxy-terminated polyether block siloxane to octamethylcyclotetrasiloxane is 1:20.

[0041] The alkali catalyst is tetramethylammonium hydroxide, and the catalyst consumption is 0.055%.

[0042]The epoxy-terminated capping age...

Embodiment 3

[0047] A preparation method of hyperbranched polyether amino block silicone, comprising the steps of:

[0048] (1) Preparation of polyether / epoxy block silicone oil:

[0049] Add the prepared end-epoxy head-sealing agent and octamethylcyclotetrasiloxane according to a certain ratio, and add the solvent isopropanol in a three-port reaction kettle with a nitrogen filling device and a reflux condenser, and the dosage is the reactant 30% of the total amount. Stir and heat up to 50°C for dehydration under reduced pressure for 30 minutes, add a certain amount of alkali catalyst, continue to heat up to 105°C, and keep warm for 4.5 hours; then remove low boilers under reduced pressure to obtain polyether / epoxy block silicone oil.

[0050] The molar ratio of the epoxy-terminated polyether block siloxane to octamethylcyclotetrasiloxane is 1:17.

[0051] The alkali catalyst is tetramethylammonium hydroxide, and the catalyst consumption is 0.045%.

[0052] The epoxy-terminated capping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com