Preparation method of pickering emulsion type asa papermaking sizing agent

A sizing agent and emulsion type technology, applied in the field of papermaking sizing agent preparation, can solve the problems of large amount of particulate components added, low ASA emulsion concentration, unfavorable emulsion storage, etc., achieve high sizing performance, increase concentration and Stability, the effect of improving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

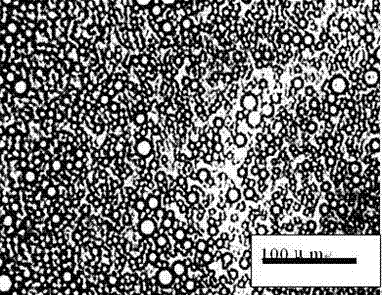

Image

Examples

Embodiment 1

[0025] Preparation of inorganic-organic composite nano-solid particle emulsifier: nano-scale sodium chloride modified sodium-based montmorillonite (the original soil was obtained from Lin’an, Zhejiang) and cetyltrimethylammonium chloride (CTAC) according to Mix and disperse in water at a mass ratio of 4:1, stir and react at a constant temperature of 65°C for 1 hour to obtain a suspension; extract the suspension, and wash the solids obtained by the extraction with water repeatedly until no trace is detected in the washing waste liquid. Chloride ion, the solid is dried at 80°C and ground through a 200-mesh sieve, and the sieve residue is the nano-solid emulsifier;

[0026] Preparation of Pickering emulsion type ASA sizing agent: Weigh a certain amount of industrial product octadecenyl succinic anhydride (ODSA, purchased from Kemira Chemicals Company), and disperse the above-prepared nano-solid particle emulsifier and magnesium chloride in a desiccated Stir in deionized water for...

Embodiment 2

[0029] Preparation of inorganic-organic composite nano-solid particle emulsifier: Nano-scale sodium fluoride modified montmorillonite (the original soil was taken from Zibo, Shandong), cetyltrimethylammonium chloride (CTAC) according to 4: Mix and disperse in deionized water at a ratio of 1, heat and stir in a constant temperature water bath at 60°C for 1 hour to obtain a suspension; extract the suspension, and wash the extracted solid with water repeatedly until no Chloride ions, then dry the solid at 105°C and grind through a 200-mesh sieve, and the sieve residue is a nano-solid particle emulsifier;

[0030] Preparation of Pickering emulsion type ASA sizing agent: Weigh a certain amount of industrial grade octadecenyl succinic acid (ODSA, obtained from Shandong Chenming Paper Co., Ltd.), and disperse the above-prepared nano-solid particle emulsifier and magnesium chloride in a Stir in deionized water for 5 minutes to obtain a solid particle emulsifier suspension, the amount ...

Embodiment 3

[0033] Preparation of inorganic-organic composite nano-solid particle emulsifier: Nano-scale sodium-based modified montmorillonite (the original soil was obtained from Liaoning), cetyltrimethylammonium chloride (CTAC) according to the ratio of 4.2:1 Proportionally mixed and dispersed in deionized water, heated and stirred in a constant temperature water bath at 80°C for 2 hours to obtain a suspension; extract the suspension, and wash the solid obtained by the extraction with water repeatedly, until the washing waste liquid is detected to be free of chloride ions Then dry the solid at 105°C and grind it through a 200-mesh sieve, and the sieve residue is a nano-solid particle emulsifier;

[0034] Preparation of Pickering emulsion type ASA sizing agent: Weigh a certain amount of industrial grade octadecenyl succinic acid (ASA, purchased from Kemira Chemicals Co., Ltd.), and disperse the above-mentioned nano-solid particle emulsifier and magnesium sulfate in Stir in deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com