Alkenyl succinic anhydride sizing agent as well as preparation method and application thereof

A technology of alkenyl succinic anhydride and alkenyl succinic acid, which is applied in the field of papermaking, can solve the problems that the adverse effects of surfactants cannot be completely avoided, the amount of surfactants is reduced, and the concentration of ASA emulsion is low, and the cost of emulsification is low. Improved glue performance and good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

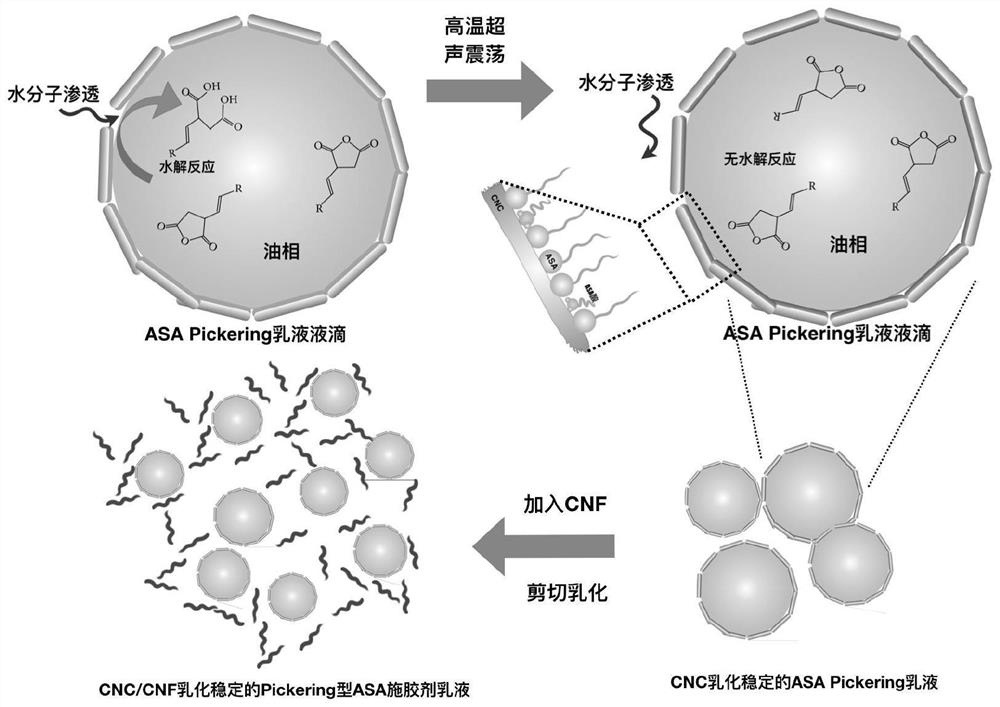

[0028] The invention provides a kind of preparation method of alkenyl succinic anhydride sizing agent, comprises the following steps:

[0029] Alkenyl succinic anhydride and cellulose nanocrystal dispersion are mixed for first emulsification to obtain ASA-1 emulsion;

[0030] The ASA-1 emulsion is ultrasonically treated, and the obtained emulsion is mixed with nanocellulose fibers for second emulsification to obtain an alkenyl succinic anhydride sizing agent.

[0031] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0032] In the invention, the alkenyl succinic anhydride and the cellulose nano crystal dispersion liquid are mixed for the first emulsification to obtain the ASA-1 emulsion. In the present invention, the alkenyl succinic anhydride (ASA) is preferably at least one of dodecyl to octadecyl alkenyl succinic anhydride monomers; more preferably tetradecy...

Embodiment 1

[0049] CNC (the CNC prepared by the hydrochloric acid method) is dispersed in deionized water, dispersed with a high-speed shear disperser under the condition of 5000rpm, and prepared into a CNC dispersion liquid with a mass fraction of 0.05%, and then ASA (dodecenyl succinic anhydride ) was added to the CNC dispersion liquid according to the volume ratio of 1:20, and the first emulsification was carried out with a high-speed shear disperser at 2000r / min and 5°C for 2 minutes; ultrasonic treatment was performed at 55°C for 5 minutes, and then 1.5% (relatively The mass fraction of the CNC dispersion liquid) of CNF was emulsified for 2 minutes with a high-speed shear disperser at 5000 r / min at 5°C to obtain a Pickering-type ASA sizing agent emulsion with stable CNC / CNF emulsification.

Embodiment 2

[0051] CNC (CNC-S) is dispersed in deionized water, dispersed with a high-speed shear disperser under the condition of 8000rpm, and prepared into a CNC dispersion liquid with a mass fraction of 0.5%, and then ASA (dodecenyl succinic anhydride and Octenyl succinic anhydride mixture, each 50%) was added to the CNC dispersion at a volume ratio of 1:10, and the first emulsification was carried out for 5 minutes with a high-speed shear disperser at 5000r / min at 25°C; at 75°C After ultrasonic treatment for 8 minutes, 1.0% CNF was added, and the second emulsification was carried out with a high-speed shear disperser at 8000r / min and 25°C for 3 minutes to obtain a Pickering-type ASA paper sizing agent emulsion with stable CNC / CNF emulsification.

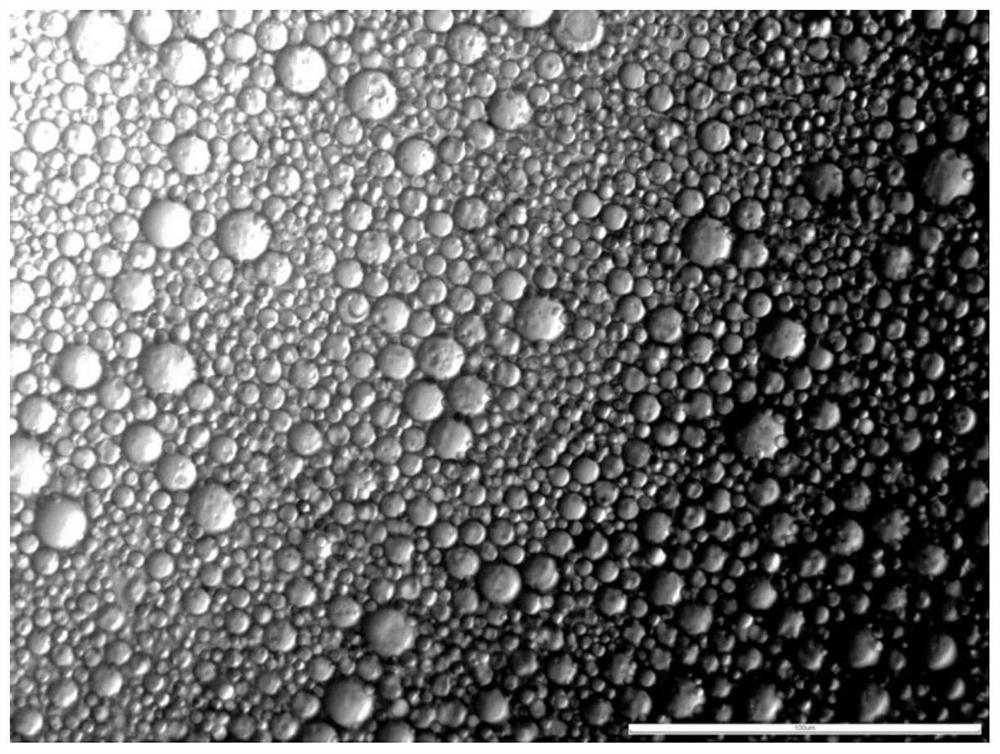

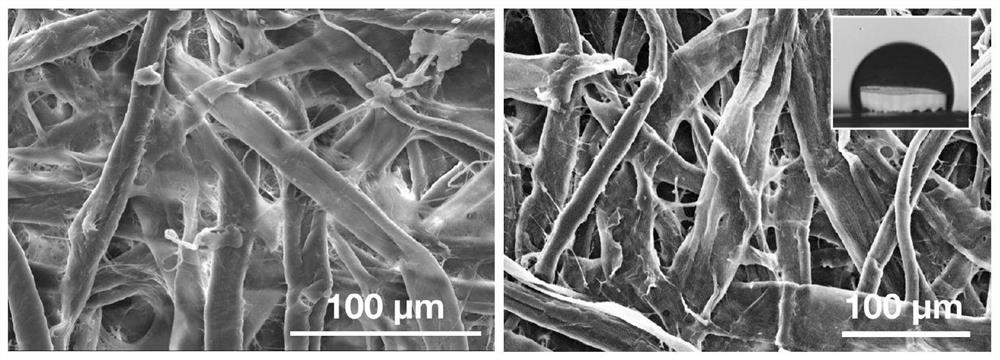

[0052] figure 1 Micrograph (400 times, scale is 100 μ m) of the Pickering type ASA sizing agent emulsion of the CNC / CNF emulsification stability prepared for embodiment 2; As can be seen from the figure, the obtained emulsion droplet is a un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com