Emulsified biomass fuel oil and emulsifying method thereof

A technology of biomass crude oil and emulsifier, which is used in fuel, petroleum industry, fuel additives and other directions, can solve the problems of low utilization rate, and achieve the effects of low ash content, low emulsification cost, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

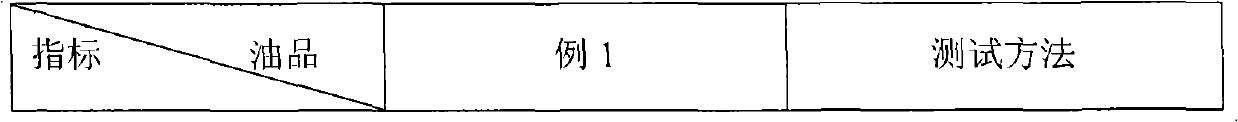

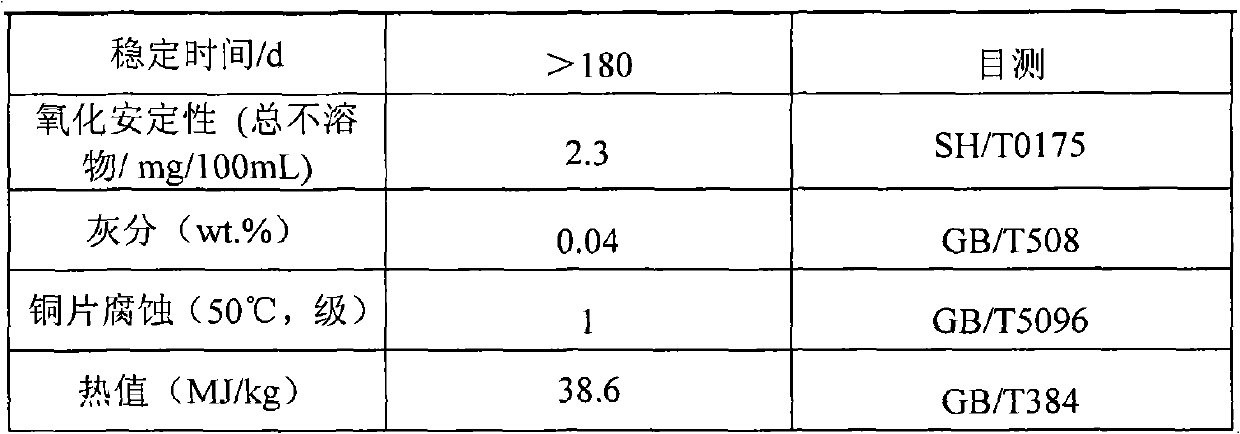

[0026] Example 1 Take 50g of biomass crude oil, filter out coarse impurities through a filter screen with a pore size of 1mm, and then centrifuge at 5000rpm for 20min to remove the heavy components; 0.8g of octylphenyl polyoxyethylene ether and 0.2g of fat Add alcohol polyoxyethylene ether to 50g of biomass crude oil and stir evenly and place it in container a, add 4.4g sorbitan monooleate into 943g No. 0 diesel oil and stir evenly, place it in container b, and then put the Add the solution together into a high-shear homogeneous emulsifier [HLB=5.97], at 40°C, 2000rpm, fully shear and stir for 30 minutes, then add 0.3g of bis(lauryl acrylate)-sulfide and 0.1g After adding isooctyl nitrate and 1.2 g of n-butanol, continue stirring to make the solution appear a homogeneous phase, stop stirring, and obtain emulsified biomass crude oil after cooling to room temperature.

[0027] Example 2 Take 150g of biomass crude oil, filter out the coarse impurities, and then centrifuge at 5000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com