A method for synthesizing petroleum sulfonate in a microreactor

A technology of petroleum sulfonate and microreactor, which is used in the preparation of sulfonate, chemical instruments and methods, chemical industry and other directions, can solve the problems of short residence time, long residence time, and many side reactions, and achieves less consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

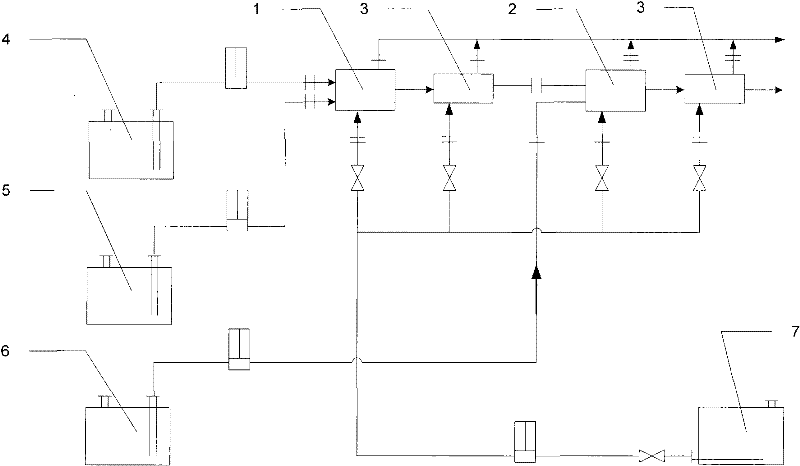

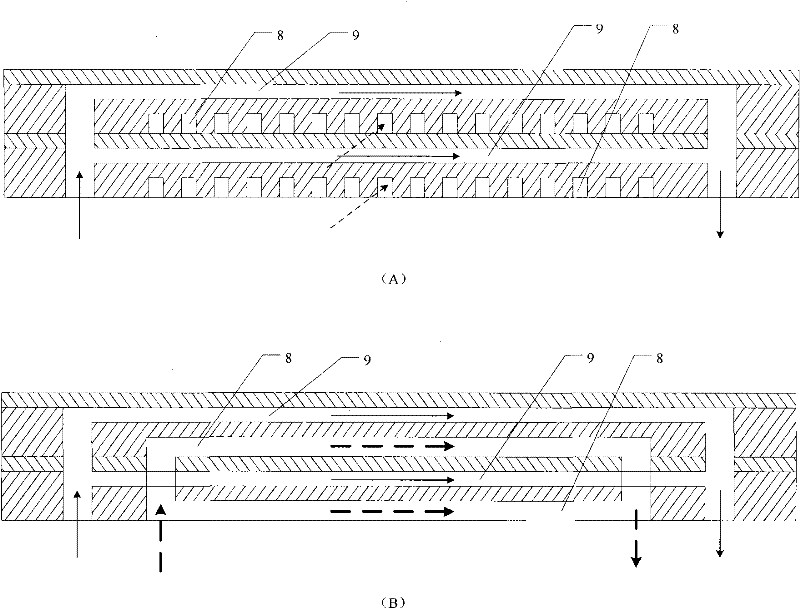

Method used

Image

Examples

Embodiment 1

[0029] Dalian Institute of Chemical Physics Microreactor: The characteristic size of the micro-mixing and micro-heat exchange channels is 420 μm, the volume of the mixing channel is 240 μl, and the volume of the heat exchange channel is 480 μl (2 pieces)

[0030] Heat exchange medium: tap water, 650ml / min (reactor 1), 430ml / min (heat exchanger 3)

[0031] Sulfonating agent: liquid phase SO 3 + Dichloroethane, SO 3 %(mass)=28.6%, density 1.36g / ml

[0032] Raw material oil: 180~550℃ distillate oil (diesel oil + wax oil) + dichloroethane, mass ratio (1:3): 4, density 1.07g / ml

[0033] Sulfonating agent flow rate: 18.4g / min

[0034] Raw oil flow rate: 38.8g / min

[0035] SO 3 Mass ratio to distillate oil: 0.27

[0036] The temperature of the petroleum sulfonic acid stream at the outlet of the sulfonation reactor: 58°C

[0037] Neutralizing liquid active substance content: 18.2%

[0038] Active matter content after dehydration and solvent removal: 49.1%

[0039] Interfacial...

Embodiment 2

[0041] Dalian Institute of Chemical Physics Microreactor: The characteristic size of the micro-mixing and micro-heat exchange channels is 420 μm, the volume of the mixing channel is 240 μl, and the volume of the heat exchange channel is 480 μl (2 pieces)

[0042] Heat exchange medium: tap water, 590ml / min (reactor 1), 550ml / min (heat exchanger 3)

[0043] Sulfonating agent: liquid phase SO 3 + Dichloroethane, SO 3 %(mass)=28.6%, density 1.36g / ml

[0044] Raw material oil: 180~550℃ distillate oil (diesel oil + wax oil) + dichloroethane, mass ratio (1:3): 4, density 1.07g / ml

[0045] Sulfonating agent flow rate: 3.4g / min

[0046] Raw oil flow rate: 9.4g / min

[0047] SO 3 Mass ratio to distillate oil: 0.20

[0048] The temperature of the petroleum sulfonic acid stream at the outlet of the sulfonation reactor: 35~42°C

[0049] Neutralizing liquid active substance content: 15.5%

[0050] Active substance content after dehydration and solvent removal: 43.4%

[0051] Interfa...

Embodiment 3

[0053] Dalian Institute of Chemical Physics Microreactor: The characteristic size of the micro-mixing and micro-heat exchange channels is 420 μm, the volume of the mixing channel is 240 μl, and the volume of the heat exchange channel is 480 μl (2 pieces)

[0054] Heat exchange medium: tap water, 670ml / min (reactor 1), 270ml / min (heat exchanger 3)

[0055] Sulfonating agent: liquid phase SO 3 + Dichloroethane, SO 3 %(mass)=28.6%, density 1.36g / ml

[0056] Raw material oil: 180~550℃ distillate oil (diesel oil + wax oil) + dichloroethane, mass ratio (1:3): 4, density 1.07g / ml

[0057] Sulfonating agent flow rate: 16.1g / min

[0058] Raw oil flow rate: 33.9g / min

[0059] SO 3 Mass ratio to distillate oil: 0.27

[0060] The temperature of the petroleum sulfonic acid stream at the outlet of the sulfonation reactor: 56°C

[0061] Active substance content in neutralizing solution: 18.2%, the ratio of monosulfonate to bisulphonate in the active substance is ~1.18

[0062] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com