Environmental-friendly micro emulsion cutting fluid

A cutting fluid, an environmentally friendly technology, applied in the field of cooling and lubricating media in metal cutting and grinding processes, can solve the problems of high price, achieve long service life, overcome easy deterioration and odor, and have good cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

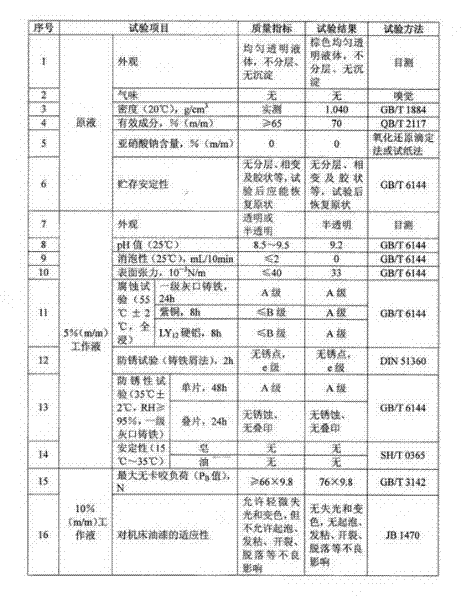

Image

Examples

Embodiment 1

[0037] Embodiment 1: the present invention is made into the material parts by weight of active ingredient and consists of:

[0038] No. 10 Industrial White Oil 10 Sodium Petroleum Sulfonate 8 Oleic Acid 6

[0039] Triethanolamine 10 Alkylphenol polyoxyethylene ether OP-10 10

[0040] Alkyl alcohol amide phosphate 6503 1 Rust inhibitor monomer 10

[0041] Tetradecyl Alcohol or Stearyl Alcohol 1 Benzotriazole 1

[0042] Sodium tetraborate 1 Sodium carbonate 1

[0043] Triazine compound / benzisothiazolinone fungicide (NEUF652) 1

[0044] Defoamer MS-455 1 water 30;

[0045] Among them: the antirust agent monomer is a water-soluble amine soap synthesized by twelve-carbon dibasic fatty acid and triethanolamine. The dodecyl-carbon dibasic fatty acid and triethanolamine are obtained by stirring at 80°C to 90°C for 2 hours at a mass ratio of 1:4. .

[0046] Production Process:

[0047] 1. Preparation of oil phase system:

[0048] Add No. 10 industrial white oil into the reactio...

Embodiment 2

[0055] Embodiment 2 The present invention is made into the material parts by weight of active ingredient and consists of:

[0056] No. 10 industrial white oil 17.5 sodium petroleum sulfonate 11.5 oleic acid 9

[0057] Triethanolamine 15 Alkylphenol polyoxyethylene ether OP-10 13

[0058] Alkyl alcohol amide phosphate 6503 2.5 Rust inhibitor monomer 15

[0059] Tetradecyl Alcohol or Stearyl Alcohol 5 Benzotriazole 1

[0060] Sodium tetraborate 5 Sodium carbonate 2.5

[0061] Triazine compound / benzisothiazolinone fungicide (NEUF652) 1.5

[0062] Defoamer MS-455 0.25 water 40;

[0063] Among them: the antirust agent monomer is a water-soluble amine soap synthesized by twelve-carbon dibasic fatty acid and triethanolamine. The dodecyl-carbon dibasic fatty acid and triethanolamine are obtained by stirring at 80°C to 90°C for 2 hours at a mass ratio of 1:4. .

[0064] Production technology is identical with embodiment 1.

Embodiment 3

[0065]Example 3 The present invention is made of active ingredients of materials in parts by weight: No. 10 industrial white oil 25 sodium petroleum sulfonate 15 oleic acid 12

[0066] Triethanolamine 20 Alkylphenol polyoxyethylene ether OP-10 16

[0067] Alkyl alcohol amide phosphate 6503 5 Rust inhibitor monomer 20

[0068] Tetradecyl Alcohol or Stearyl Alcohol 10 Benzotriazole 2

[0069] Sodium tetraborate 10 Sodium carbonate 5

[0070] Triazine compound / benzisothiazolinone fungicide (NEUF652) 3

[0071] Defoamer MS-455 0.5 water 50;

[0072] Among them: the antirust agent monomer is a water-soluble amine soap synthesized by twelve-carbon dibasic fatty acid and triethanolamine. The dodecyl-carbon dibasic fatty acid and triethanolamine are obtained by stirring at 80°C to 90°C for 2 hours at a mass ratio of 1:4. .

[0073] Production technology is identical with embodiment 1.

[0074] The product of the invention is used in mechanical processing such as turning, boring,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com