Preparation method of nanometer enhanced ultraviolet curing antifogging agent

A nano-enhanced, anti-fogging technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of insufficient wear resistance, low hardness, limited application, etc., and achieve efficient dispersion, high hardness, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

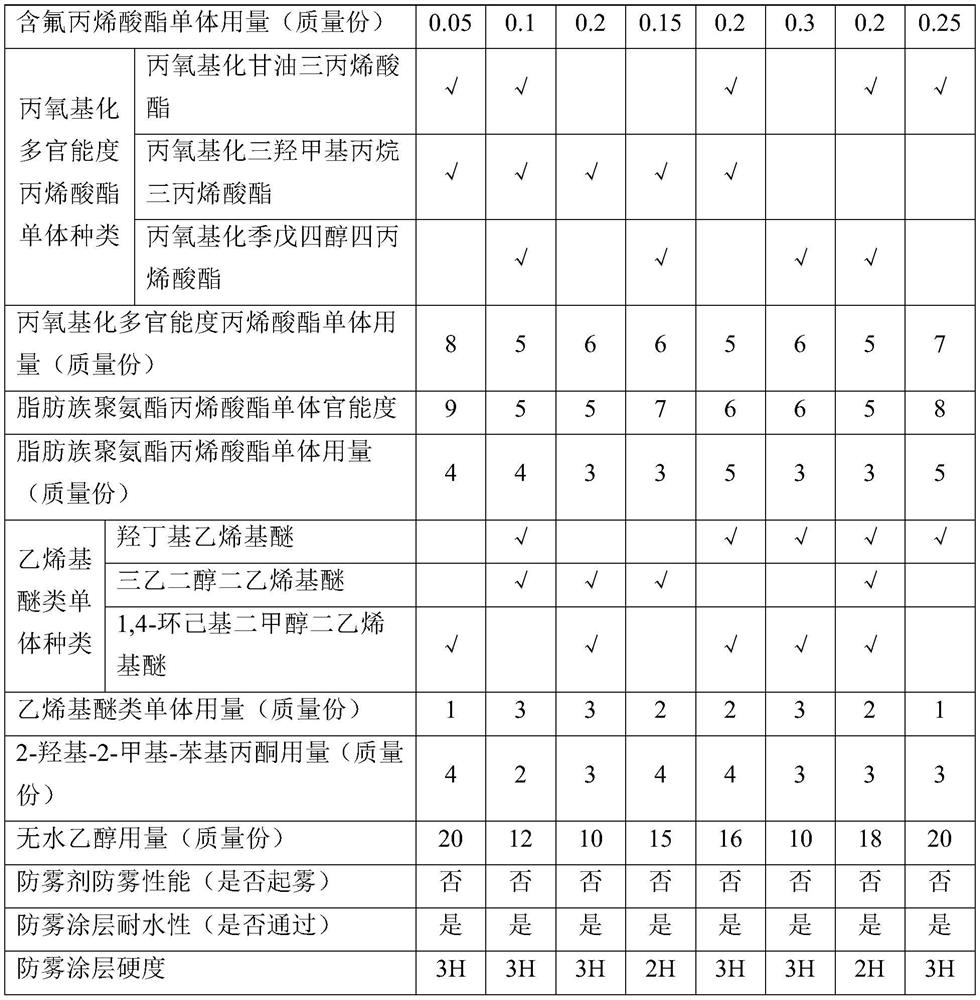

Examples

preparation example Construction

[0027] The preparation method of the nano-enhanced ultraviolet curing antifogging agent of the present invention comprises the following steps:

[0028] (1) Preparation of carbon nitride nanoparticle dispersion

[0029] Under stirring conditions, add 1 mol / L sulfuric acid aqueous solution dropwise to 80°C, 0.5 mol / L melamine aqueous solution to form a white suspension, and continue stirring for 2 hours to obtain a precipitate; filter the precipitate and wash it with distilled water five times, Then washed three times with absolute ethanol, and dried at 60° C. for 24 hours to obtain melamine sulfate.

[0030] Mix and stir 3-5 parts by mass of melamine sulfate and 2-3 parts by mass of urea evenly, conduct heat treatment in a tube furnace, control the heating rate at 8°C / min, and heat-treat at 400°C for 8h; after naturally cooling to room temperature, Carbon nitride particles are obtained.

[0031] Mix 10 parts by mass of carbon nitride particles, 80 parts by mass of deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com