Method for dispersing carbon nano-tube

A carbon nanotube, dispersing technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of reduced inherent properties, unfavorable application, damage to the electronic structure of carbon nanotubes, etc., and achieves low usage and stability. Good, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

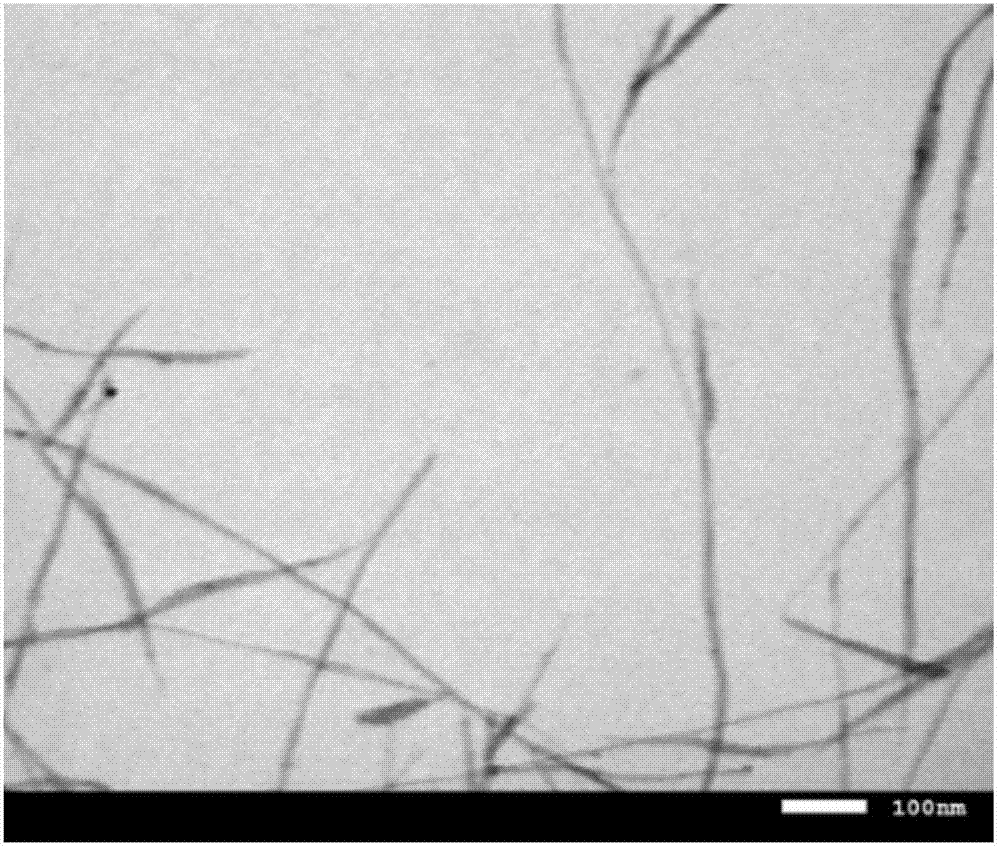

[0036] Place 3mg of 2,3,6,7,10,11-hexahydroxytriphenylene and 1.5mg of single-walled carbon nanotubes (HiPco) in a 60ml ultrasonic container, then add 30mL of water, and seal the bottle with plastic wrap After the mouth, it was fixed in the ultrasonic water tank of the ultrasonic cleaning machine, and the ultrasonic treatment was performed for 2 days. During the ultrasonic process, the temperature of the water tank was controlled at 20 °C by using a circulating water device. After the sonication, the solution was black, which proved that a considerable number of carbon nanotubes were uniformly dispersed in the water. Carefully transfer the dispersion to a centrifuge tube and centrifuge at a centrifugal force of 25700g for 1 hour in order to remove bundles of carbon nanotubes that are not uniformly dispersed. The supernatant liquid is taken out, and a uniformly dispersed carbon nanotube dispersion liquid can be obtained.

[0037] figure 1 The single-walled carbon nanotube di...

Embodiment 2

[0040] Place 3.0mg of 2,3,6,7,10,11-hexahydroxytriphenylene and 1.5mg of single-walled carbon nanotubes (HiPco) in a 60ml ultrasonic container, then add 30mL of methanol, and seal with plastic wrap After the bottle mouth, fix it in the ultrasonic water tank of the ultrasonic cleaning machine, and sonicate for 3 days. During the ultrasonic process, the temperature of the water tank was controlled at 15 °C by using a circulating water device. After the sonication, the solution was black, which proved that a considerable number of carbon nanotubes were uniformly dispersed in the water. Carefully transfer the dispersion to a centrifuge tube and centrifuge at a centrifugal force of 1029g for 1 hour to remove undispersed carbon nanotube bundles. Take out the supernatant to obtain a uniformly dispersed black carbon nanotube dispersion. The concentration of the carbon nanotubes in the dispersion liquid can be calculated through the absorption spectrum, and the yield of the carbon na...

Embodiment 3

[0042] Place 3mg of 2,3,6,7,10,11-hexahydroxytriphenylene and 0.75mg of single-walled carbon nanotubes (HiPco) in a 60ml ultrasonic container, then add 30mL of water, and seal the bottle with plastic wrap After the mouth, it was fixed in the ultrasonic water tank of the ultrasonic cleaning machine, and the ultrasonic treatment was performed for 2 days. During the ultrasonic process, the temperature of the water tank was controlled at 15 °C by using a circulating water device. After the sonication, the solution was black, which proved that a considerable number of carbon nanotubes were uniformly dispersed in the water. Carefully transfer the dispersion to a centrifuge tube and centrifuge at a centrifugal force of 25,700 g for 1.5 hours to remove undispersed carbon nanotube bundles. Take out the supernatant to obtain a uniformly dispersed black carbon nanotube dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com