Preparation method of oil-soluble organic molybdenum friction modifier

A technology of friction modifier and organic molybdenum, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of not being suitable for large-scale industrial production, high production cost, and not easy to filter, etc., and achieve good oil solubility and anti-oxidation ability, low production cost, good wear reduction and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

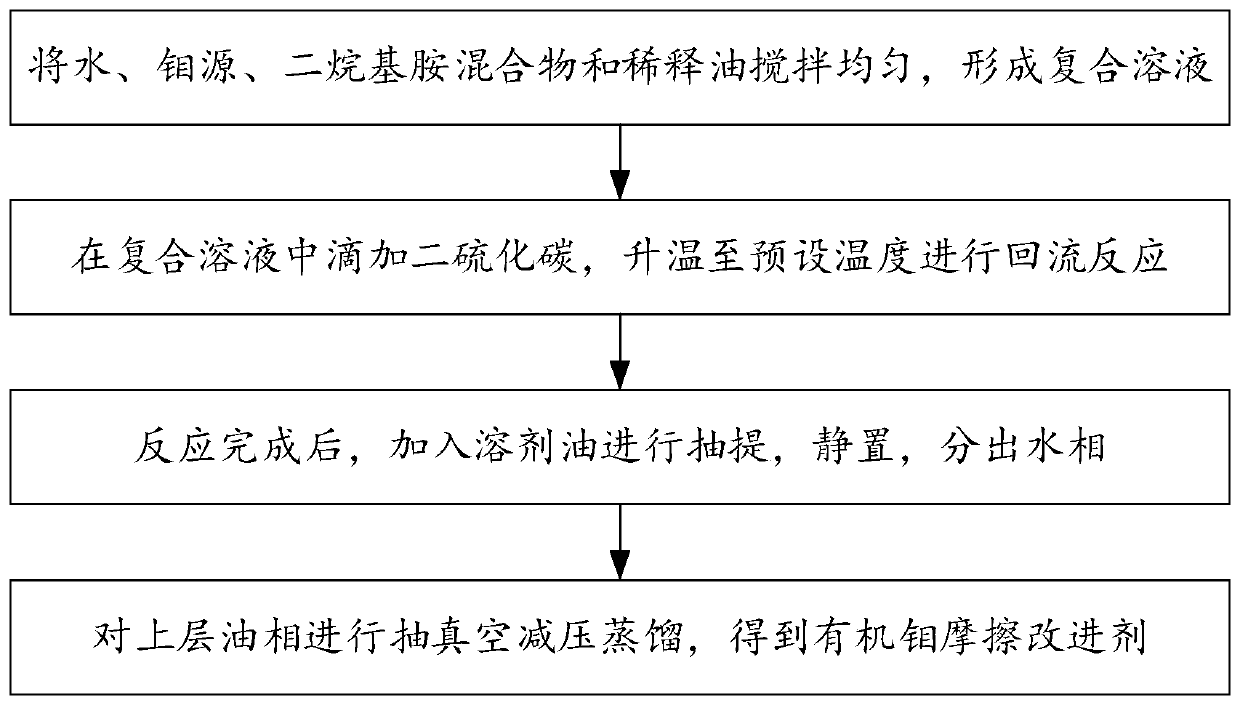

[0037] Such as figure 1 As shown, the invention provides a kind of preparation method of oil-soluble organic molybdenum friction modifier, comprising:

[0038] S1. Stir the water, molybdenum source, dialkylamine mixture and diluent oil evenly to form a composite solution, and keep the temperature of the composite solution at 5-14°C; wherein,

[0039] The molybdenum source includes one or more of ammonium heptamolybdate, sodium molybdate and molybdenum trioxide, preferably the molybdenum source is ammonium heptamolybdate;

[0040] Dialkylamine mixture is the mixture of diisooctylamine and isomeric ditridecylamine or the mixture of diphenylamine and isomeric ditridecylamine; the mol ratio of diisooctylamine and isomeric ditridecylamine is (1: 5)-(5:1), the molar ratio of diphenylamine to isomeric ditridecylamine is (1:5)-(5:1).

[0041] The diluent oil is naphthenic base oil or high-boiling aromatic solvent oil, the aromatic content of naphthenic base oil is more than 40%, and...

Embodiment 1

[0053] The invention provides a preparation method of an oil-soluble organic molybdenum friction modifier, comprising:

[0054]Add 17.56 g of ammonium heptamolybdate, 36 g of water, 12.08 g of diisooctylamine, 19.01 g of isomeric ditridecylamine, and 40 g of naphthenic base oil in a 500 mL four-necked flask equipped with mechanical stirring, a thermometer, and a reflux condenser. , stirred evenly until completely dissolved; then added dropwise 15.23g of carbon disulfide at 10°C, after the dropwise addition, raised the temperature to 90°C, and refluxed for 8h; The lower water phase was taken out; then the upper oil phase was distilled under reduced pressure, the vacuum degree was -0.095 MPa, the temperature was gradually raised to 130° C., kept for 4 hours, and the temperature was lowered to obtain a brown oily product.

[0055] The measured Mo content is 10.02%, the S content is 10.99%, the mechanical impurity is 0.004%, and it is completely dissolved in the base oil.

Embodiment 2

[0057] The invention provides a preparation method of an oil-soluble organic molybdenum friction modifier, comprising:

[0058] Add 17.56g of ammonium heptamolybdate, 36g of water, 12.08g of diisooctylamine, 19.01g of isomeric ditridecylamine, and 40g of high-boiling point aromatic hydrocarbon solvent oil into a 500mL four-necked flask equipped with mechanical stirring, a thermometer, and a reflux condenser. , stir evenly until completely dissolved; then add 19g of carbon disulfide dropwise at 12°C, after the dropwise addition, raise the temperature to 95°C, and reflux for 10h; after the reaction, add 120g of 120# solvent oil, stir for 10min, stand for 30min, separate The lower water phase; then the upper oil phase was distilled under reduced pressure, the vacuum degree was -0.095MPa, the temperature was gradually raised to 120°C, kept for 6 hours, and the temperature was lowered to obtain a brown oily product.

[0059] The measured Mo content is 10.15%, the S content is 11.20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com