A kind of high-entropy alloy powder and method for preparing cladding layer by using laser

A high-entropy alloy and powder technology, which is applied in the field of preparation of high-entropy alloy powder and its laser cladding layer, can solve problems such as inability to meet actual needs, and achieve obvious solid solution strengthening effect, improved corrosion resistance, and improved alloy strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

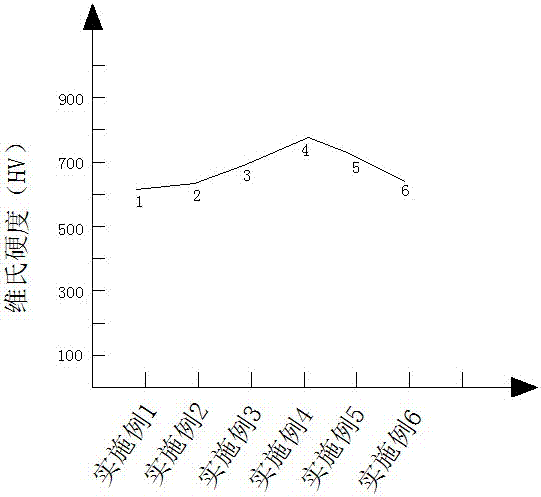

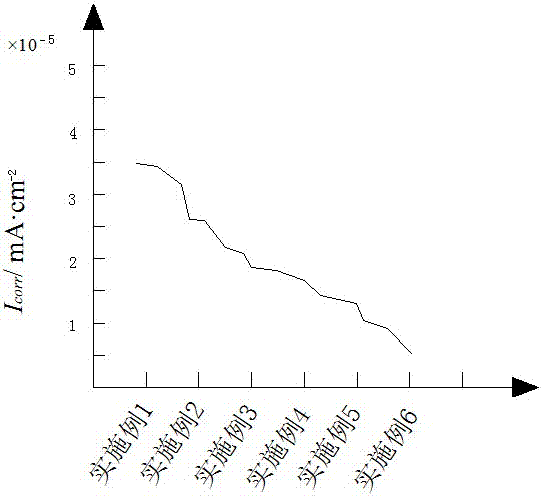

Embodiment 1

[0040] A high-entropy alloy powder, composed of Cr, Fe, Ni, Ti, Mo element powders, the particle size range of each element powder is 200-300 mesh, the purity of each element powder is greater than or equal to 99.9%, the Cr, Fe, Ni , Ti, Mo molar ratio is 1:1:1:0.2:0.2.

Embodiment 2

[0042] A high-entropy alloy powder, composed of Cr, Fe, Ni, Ti, Mo element powders, the particle size range of each element powder is 200-300 mesh, the purity of each element powder is greater than or equal to 99.9%, the Cr, Fe, Ni , Ti, Mo molar ratio is 1:1:1:0.5:0.5.

Embodiment 3

[0044] A high-entropy alloy powder, composed of Cr, Fe, Ni, Ti, Mo element powders, the particle size range of each element powder is 200-300 mesh, the purity of each element powder is greater than or equal to 99.9%, the Cr, Fe, Ni , Ti, Mo molar ratio is 1:1:1:0.75:0.75.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com