High-temperature-resistant solar energy selective absorbing coating with surface textured metal Mo being absorbing layer and preparation method thereof

A surface texture and absorbing coating technology, which is applied in the field of solar thermal utilization and thermal power generation, can solve the problems of complex coating production process and cost increase, and achieve the effects of expanding the scope of use, low production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Treatment of the substrate of the heat absorber: a polished stainless steel sheet with a roughness value of 1 nm is selected as the substrate of the heat absorber. Before use, wipe the surface with a cotton ball to remove impurities attached to the surface, then use stainless steel sheets to ultrasonically clean them in acetone and ethanol solvents for 20 minutes, dry them with nitrogen, and store them in a vacuum chamber for later use;

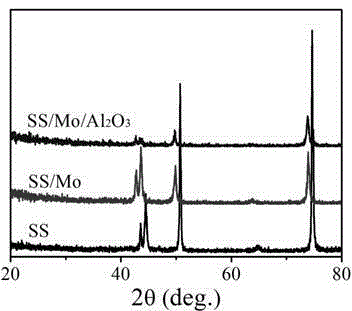

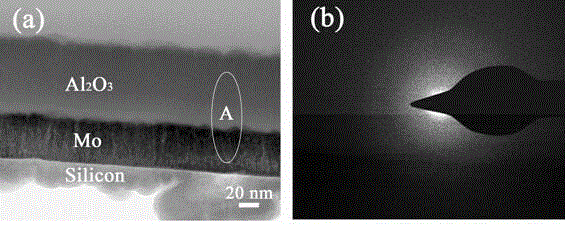

[0025] (2) Preparation of the absorbing layer: the metal Mo target with a purity of 99.99% was used as the target material, and the absorbing layer was prepared on the stainless steel substrate by DC magnetron sputtering. After installing the target, pre-pump the vacuum chamber to a background vacuum of 3.0E -6 Torr, then open the half-open valve, the argon gas fed into the vacuum chamber in pressure mode is 18mTorr, turn on the power supply of the metal Mo target, and adjust the sputtering power of the metal Mo target to 1.09W / cm ...

Embodiment 2

[0029] (1) Treatment of the substrate of the heat absorber: a polished stainless steel sheet with a roughness value of 1 nm is selected as the substrate of the heat absorber. Before use, wipe the surface with a cotton ball to remove impurities attached to the surface, then use a stainless steel sheet to ultrasonically clean it in acetone and ethanol solvents for 20 minutes, dry it with nitrogen, and store it in vacuum until use;

[0030] (2) Preparation of the absorption layer: The metal Mo target with a purity of 99.99% was used to prepare the absorption layer on the stainless steel substrate by DC magnetron sputtering. After the target is installed, pre-pump the vacuum chamber to a background vacuum of 2.8E -6 Torr, then open the half-open valve, use the pressure mode, the argon gas flowing into the vacuum chamber is 19mTorr, turn on the power supply of the metal Mo target, and adjust the sputtering power of the metal Mo target to 1.09W / cm -2 , reduce the intake of argon to...

Embodiment 3

[0034](1) Treatment of the base of the heat absorber: the same as in Example 1.

[0035] (2) Preparation of absorbing layer: Same as Example 1.

[0036] (3) Preparation of the anti-reflection layer: SiO with a purity of 99.99% is used 2 As the target, the antireflection layer was prepared by radio frequency magnetron sputtering. After the absorption layer is prepared, turn off the metal Mo target power, turn on the SiO 2 target power supply, adjust the SiO 2 The sputtering power density of the target is 6.14W / cm -2 , the flow rate of the argon gas is always kept in the pressure mode of 3mTorr, and the anti-reflection layer is prepared on the absorbing layer by radio frequency magnetron sputtering, with a thickness of 76nm.

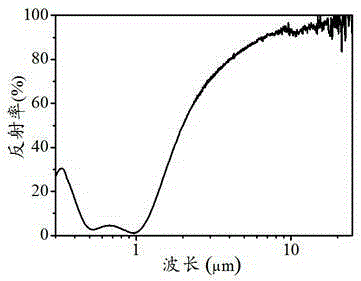

[0037] The performance of the solar selective absorbing coating is as follows: under the condition of air quality factor AM1.5, the absorptivity of the coating is 0.90, and the emissivity is 0.07. Carry out vacuum heat treatment at 2×10 -4 Under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com