A kind of composite diaphragm for lithium ion battery and preparation method thereof

A lithium-ion battery and composite separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of reducing ceramic grafting rate, product loss, low grafting rate, etc., to improve high-temperature thermal stability, The effect of improving adhesion and weakening hydrogen bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of a ceramic separator for a lithium ion battery, comprising the following steps:

[0050] (1) Grafting modification of ceramic surface: under the action of appropriate solvent and dehydrating agent, weakly acidic or neutral ceramic powder (mainly nano or submicron oxide powder, such as Al 2 O 3 , SiO 2 , TiO 2 , ferrite and other oxides) and organic monomers or polymers with sodium sulfonate or sodium carboxylate group with active hydroxyl, carboxyl group in side chain or end group under the action of dehydrating agent by "grafting" method to obtain grafting. Branched ceramic powder; or with organic monomers whose side chains do not contain active groups, under the action of coupling agents, the "grafting" method is used to polymerize on the ceramic surface to achieve the purpose of grafting and modifying the ceramics. The grafted ceramic powder is washed to obtain a graft-modified ceramic powder.

[0051] The dehydrating agents are mainly N,N-...

Embodiment 1

[0061] A preparation method of a composite diaphragm for a lithium ion battery, comprising the following steps:

[0062] a. Grafting modification of ceramic surface

[0063] The structure of the grafted monomer is as follows:

[0064]

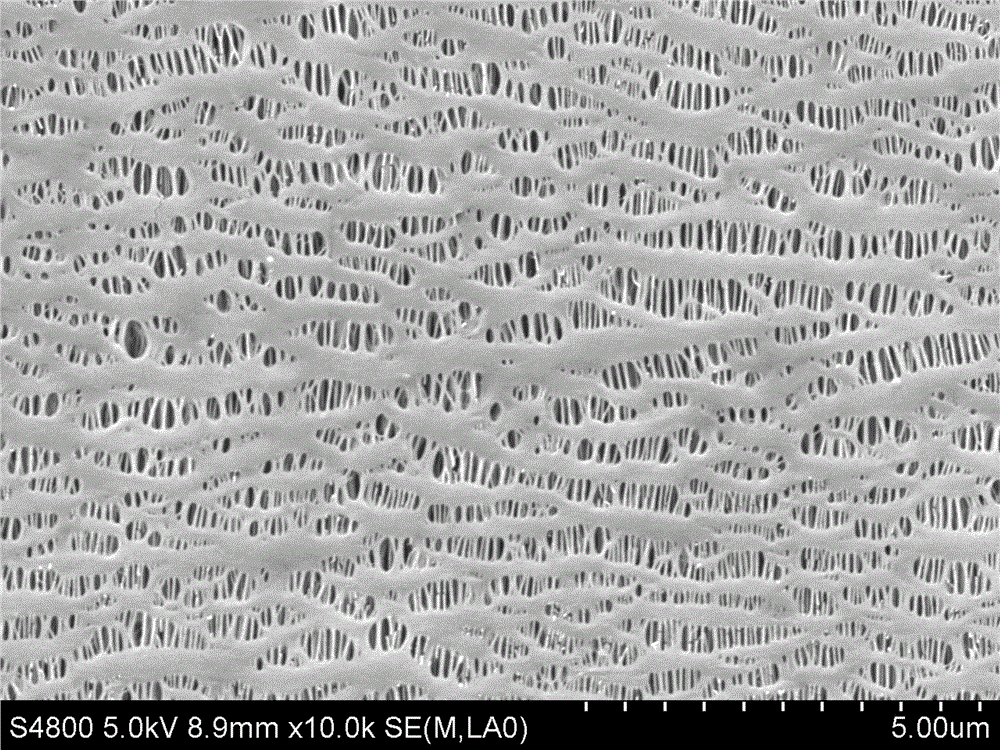

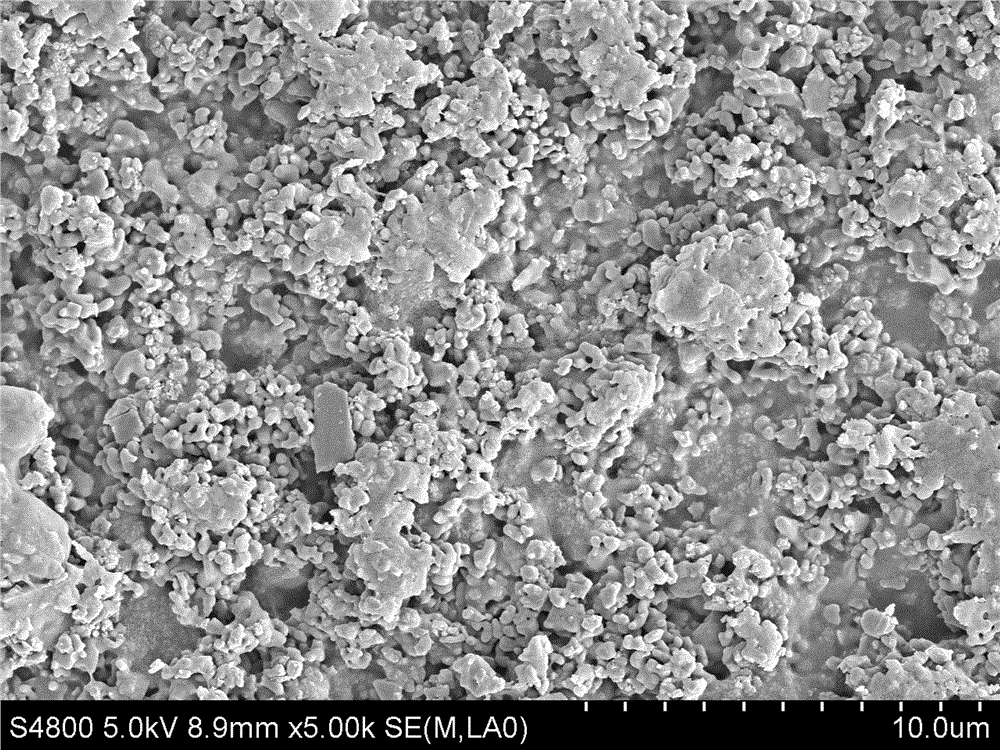

[0065] Add 10 g sub-micron aluminum oxide powder (ceramic powder), 5-40 g sodium isethionate (SHES), preferably 10-20 g, 2 g N,N-bicycle into the three-necked flask. Hexylcarbodiimide (DCC), HMPS and DCC were previously dissolved in 300 mL of isopropanol. N 2 Under the atmosphere, the water bath is heated and refluxed for 4 to 6 hours to carry out the grafting reaction. After the grafting reaction is completed, the product is centrifugally washed with ethanol and acetone for 3 to 4 times, and then vacuum-dried to constant weight to obtain the graft-modified ceramic Al. 2 O 3 .

[0066] b. Preparation of ceramic coating slurry

[0067] Mix the modified ceramics of sodium isethionate (SHES), the binder sodium polyacrylate, the mixed sol...

Embodiment 2

[0071] a. Grafting modification of ceramic surface

[0072] The structure of the grafted monomer is as follows:

[0073]

[0074] Add 10 g submicron aluminum oxide powder (ceramic powder), 5-40 g sodium hydroxypropyl methacrylate (HMPS) (preferably 10-20 g) and 2 g N into the three-necked flask, respectively. N-dicyclohexylcarbodiimide (DCC), HMPS and DCC were previously dissolved in 300 mL of isopropanol. N 2 Under the atmosphere, the water bath is heated and refluxed for 4 to 6 hours to carry out the grafting reaction. After the grafting reaction is completed, the product is centrifugally washed with ethanol and acetone for 3 to 4 times, and then vacuum-dried to constant weight to obtain the graft-modified ceramic Al. 2 O 3 .

[0075] b. Preparation of ceramic coating slurry

[0076] The modified ceramics of sodium methacrylate hydroxypropyl sulfonate (HMPS), the binder sodium polyacrylate, the mixed solvent composed of ethanol and water are stirred and mixed in a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com