Multicomponent nitride hard coating, preparation method of multicomponent nitride hard coating and application of multicomponent nitride hard coating

A hard coating and nitride technology, applied in the field of material science and engineering, can solve problems such as poor thermal stability, achieve the effects of reducing the friction coefficient, compensating for the deterioration of oxidation resistance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

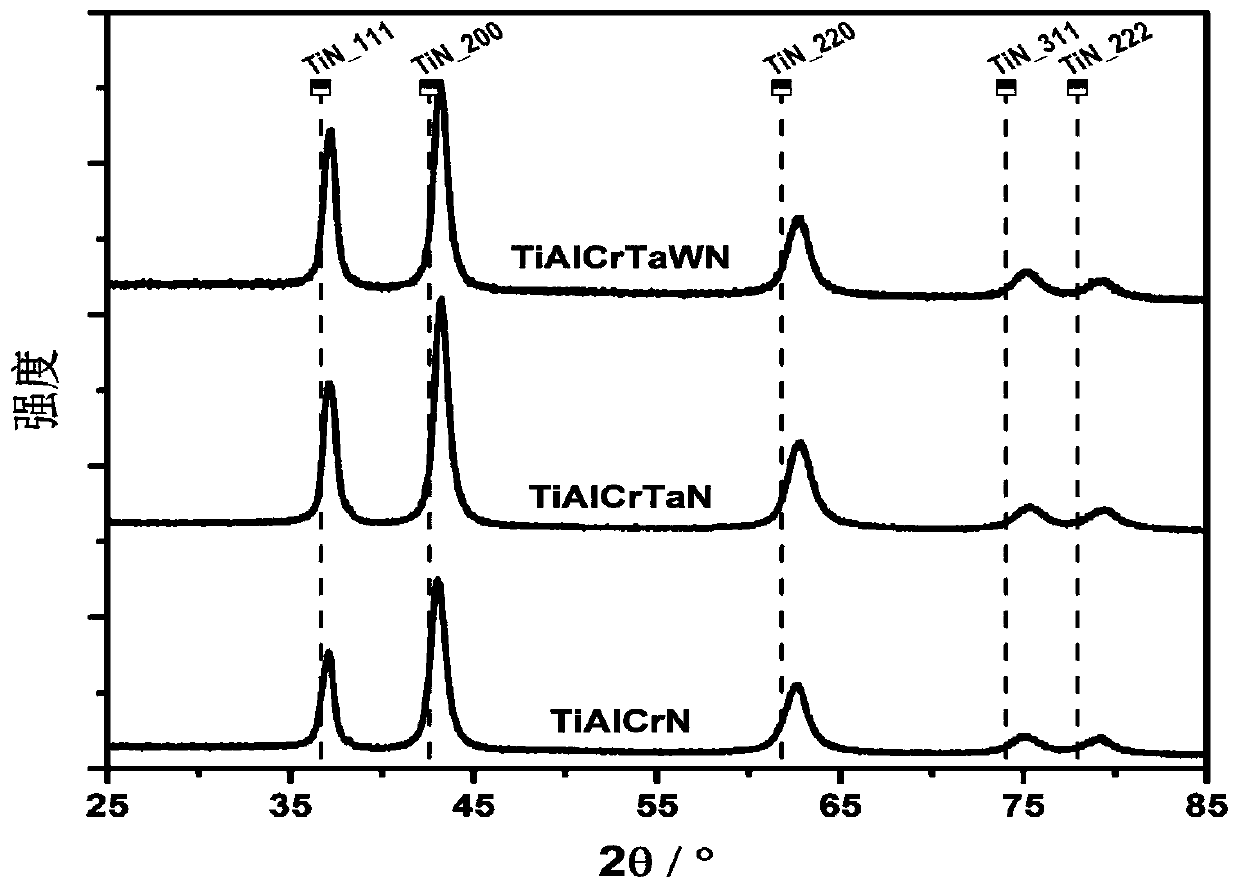

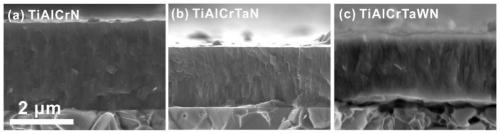

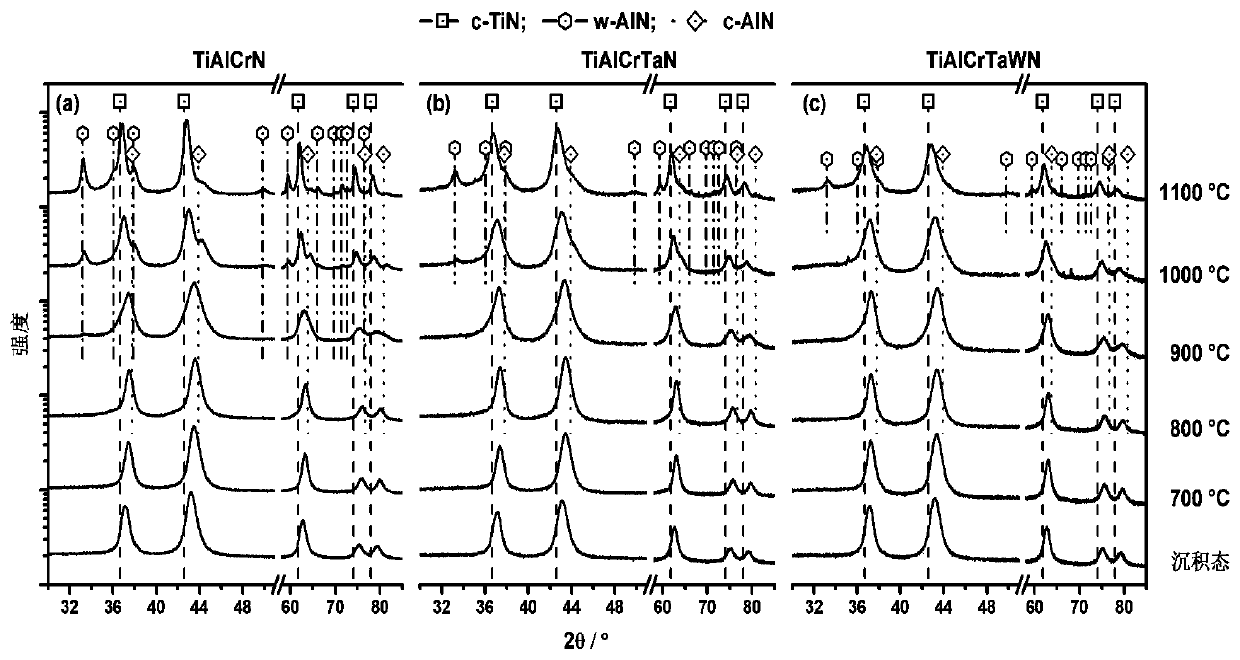

[0035] The cemented carbide substrate (WC-8wt.%Co-4wt.%TiC) was polished, then ultrasonically cleaned with acetone and absolute ethanol for 60 minutes, dried with general nitrogen, and then placed on a vacuum chamber tray. Turn on the heater to raise the temperature to 350°C, turn on the vacuum system during the heating process, and evacuate the chamber to a vacuum degree of 5×10 -3 Below Pa. Introduce Ar gas, adjust the chamber pressure to 0.55Pa, perform high-energy beam ion etching cleaning on the substrate, close the Ar gas valve, and inject N 2 The gas flow rate is 300 sccm, and the control chamber pressure is 3Pa. Adjust the bias voltage of the workpiece turret to -100V, and ignite the Ti 40 Al 50 Cr 10 For the alloy target, set the target current to 80A, deposit for 60 minutes, and prepare Ti on the surface of the cemented carbide substrate 0.42 Al 0.47 Cr 0.11 N hard coating (labeled TiAlCrN).

Embodiment 2

[0037] The difference from Example 1 is that the alloy target is Ti 30 Al 50 Cr 10 Ta 10 target, the prepared coating is Ti 0.34 Al 0.48 Cr 0.11 Ta 0.07 N (marked as TiAlCrTaN).

Embodiment 3

[0039] The difference from Example 1 is that the alloy target is Ti 20 Al 20 Cr 20 Ta 20 W 20 target, the prepared coating is Ti 0.20 Al 0.20 Cr 0.20 Ta 0.20 W 0.20 N (marked as TiAlCrTaWN).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com