Method for detecting initial position of rotor of three-stage synchronous motor

A technology for initial rotor position and synchronous motors, applied in the control of generators, electronic commutators, motor generators, etc., can solve problems such as complex implementation, achieve short detection time, simple signal injection and signal extraction methods, and easy detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

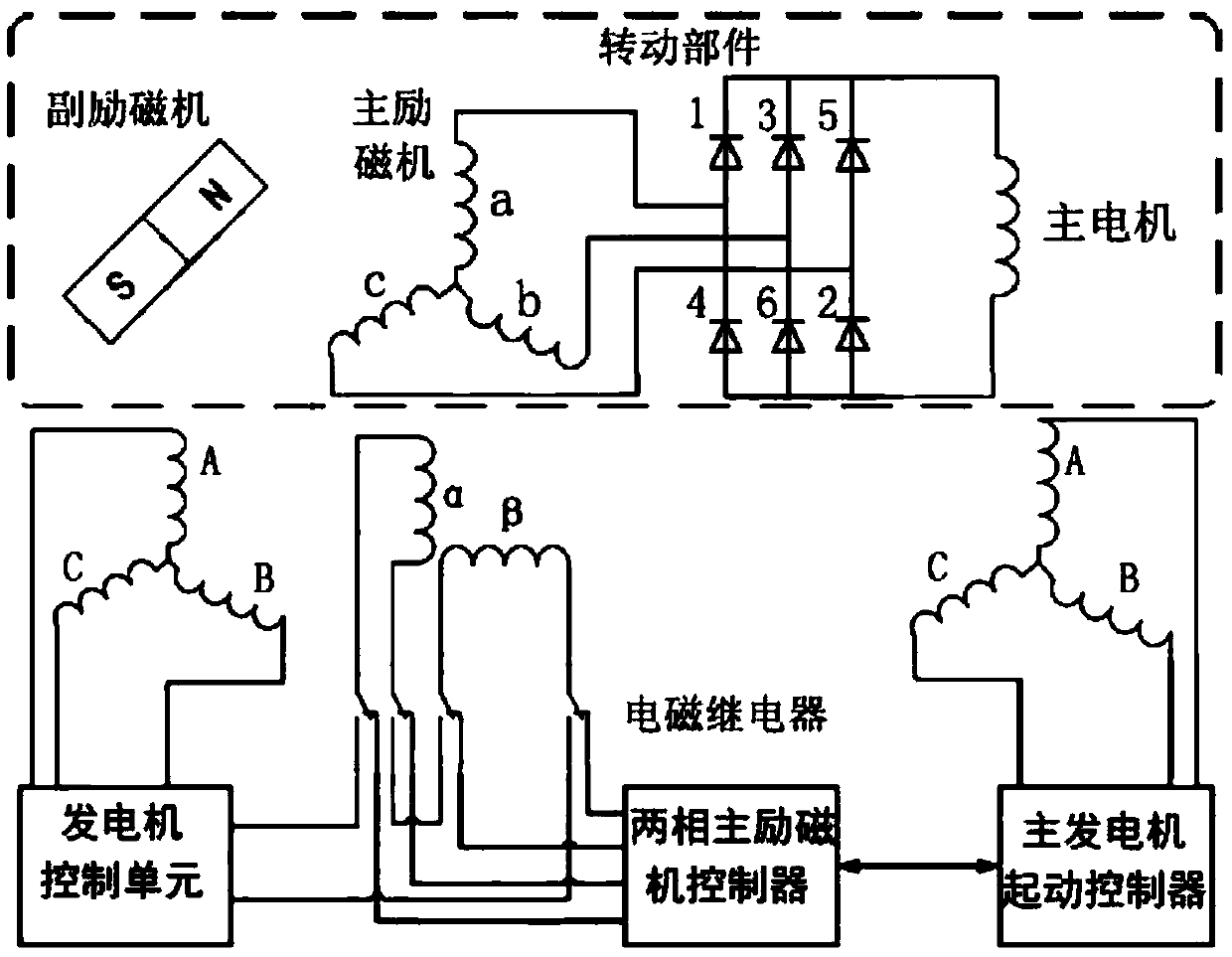

[0023] Step 1: The structure of a three-stage synchronous motor using two-phase AC excitation is as follows figure 1 shown. Firstly, the rotor of the main motor of the three-stage synchronous motor is excited. The two-phase AC excitation voltage with the same amplitude (210Vrms), the same frequency (200Hz), and a phase difference of 90° is passed to the two-phase stator windings of the main exciter. Since the electrical angle of the two-phase stator windings is also 90° in space, a rotating magnetic field will be generated in the main exciter, and the rotating magnetic field will generate a three-phase induced voltage in the three-phase winding of the rotor, and the three-phase voltage will pass through the rotating rectifier After rectification, the pulsating direct current is output to realize the excitation of the rotor of the main motor.

[0024] Step 2: I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com