Shield-arc welding device with aerating device inside tube

A technology of gas shielded welding and inflatable device, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of complex structure and complicated operation steps, and achieve the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

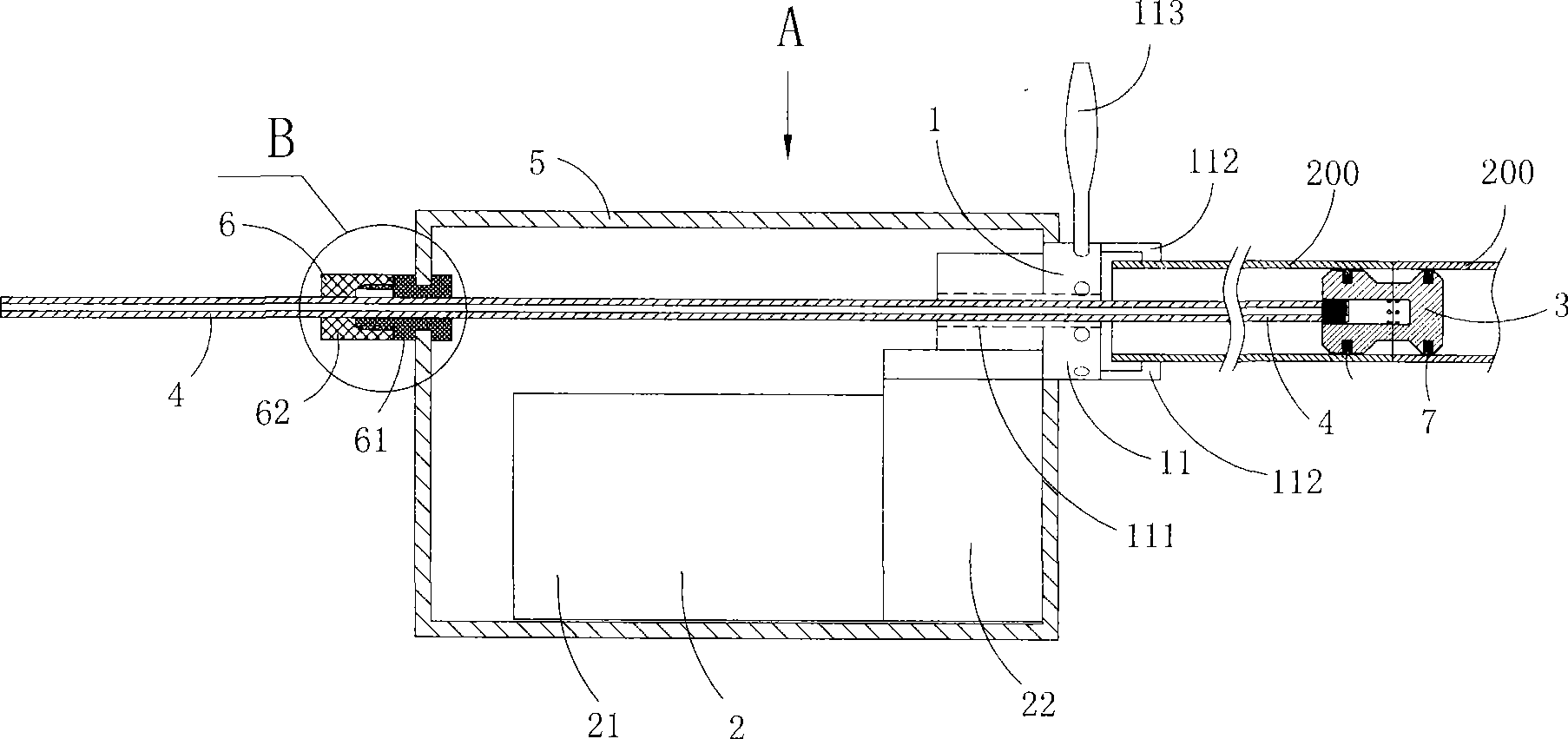

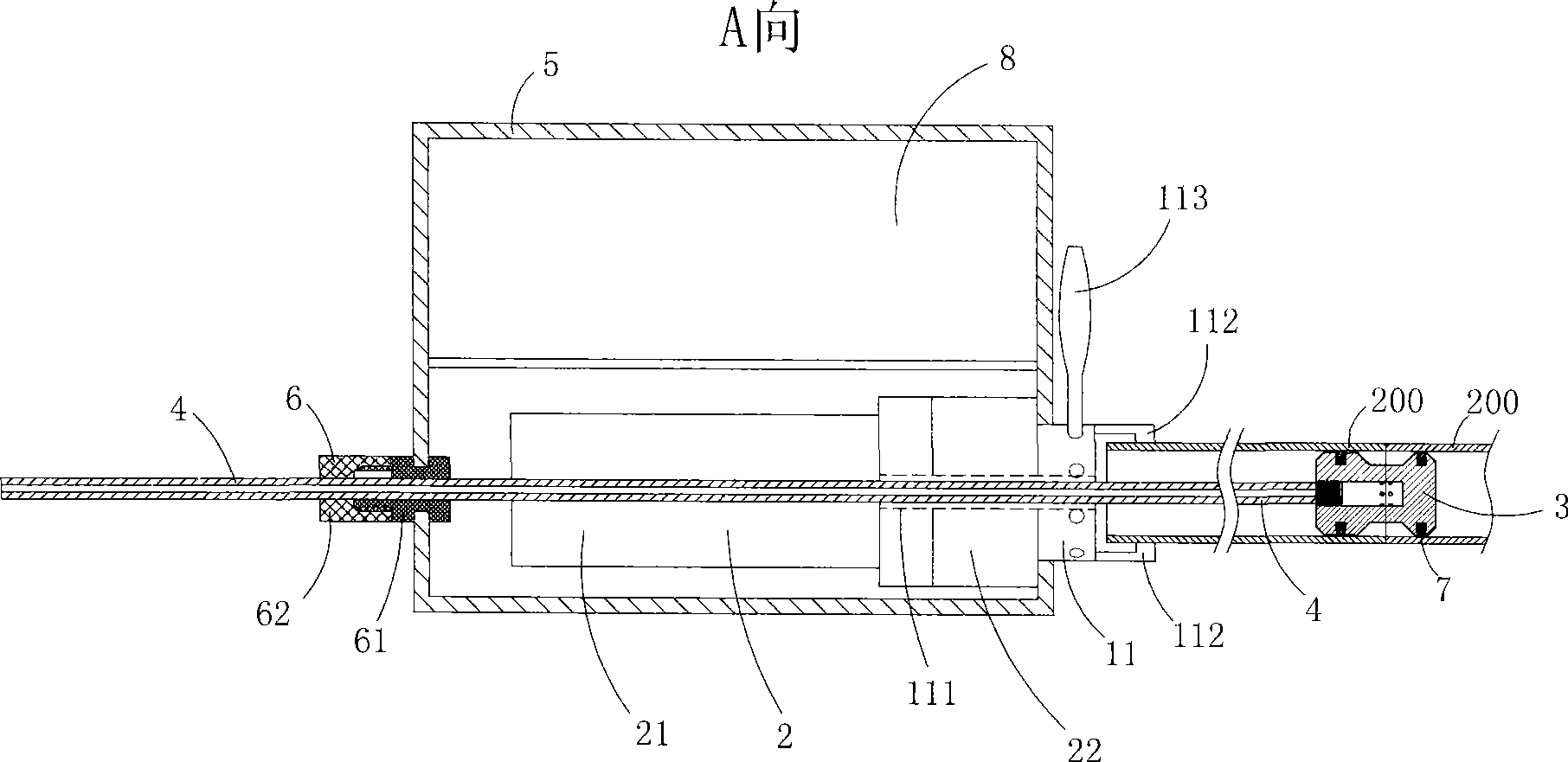

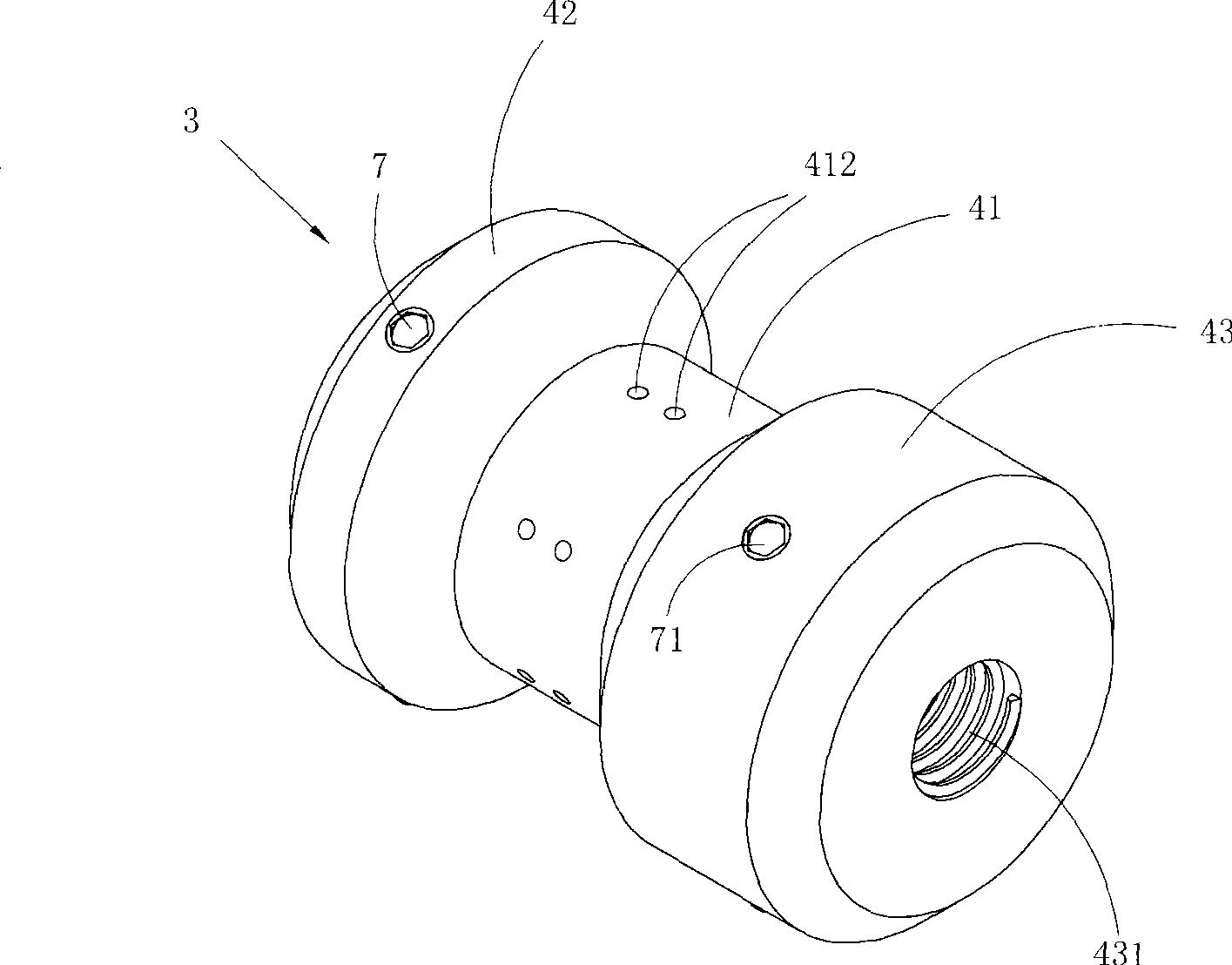

[0041] Figure 1 to Figure 5 A first embodiment of the invention is shown in which, figure 1 It is a structural schematic diagram of the first structure of the present invention; figure 2 yes figure 1 The A-direction view of the gas shielded welding device with the gas filling device in the tube shown; image 3 yes figure 1 A schematic diagram of the three-dimensional structure of the gas filling device in the tube in the gas shielded welding device with the gas charging device in the tube shown; Figure 4 yes image 3 Schematic diagram of the cross-sectional structure of the inflatable device shown in the tube; Figure 5 yes figure 1 The partial enlarged schematic diagram of B.

[0042] This embodiment is a gas shielded welding device with an inflatable device in the pipe, see figure 1 and figure 2 , including: a locking device 1 with a chuck 11 for clamping the pipe to be welded; a drive mechanism 2 for driving the chuck 11 to rotate; Gas inflating device 3 in th...

Embodiment 2

[0055] Figure 6 It is a schematic diagram of the half-section structure of the inflatable device in the tube in the second structure of the present invention, showing the second specific embodiment of the present invention.

[0056] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 , In the inflatable device 3 in the present embodiment, two rows of air outlet holes 412 are arranged on the outer surface of the inflatable part 41 along the circumferential direction. In addition, the mounting hole 44 on the first blocking portion 42 is a through hole provided with an internal thread, each of the drag reducing devices 7 includes two balls 71, a spring 72 providing elastic support for the balls, and two outer Thread retaining ring 73; According to spring 72 inside, ball 71 is arranged in the mounting hole 44 in the order that spring and ball are outside successively, and described two external thread retaining rings 73 block two entrances of ...

Embodiment 3

[0058] Fig. 7 and Fig. 8 have shown the third specific embodiment of the present invention, wherein Fig. 7 is a kind of three-dimensional structure schematic diagram of the inflatable device in the pipe in the third structure of the present invention; Fig. 8 is the half of the inflatable device in the pipe shown in Fig. 7 Schematic diagram of the sectional structure.

[0059] This embodiment is basically the same as Embodiment 1, except that: the first blocking portion 42 and the second blocking portion 43 are provided with installation holes 44, each of the drag reducing devices 7 only includes balls 71, the The ball 71 is rolled and embedded in the installation hole 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com