Reconstructable tool

A mold and module technology, applied in the field of reconfigurable molds, can solve the problems of difficult to achieve rapid conversion of different surfaces, high cost control system cost, high control system requirements, etc., to achieve simple structure, low cost, and avoid stuck. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

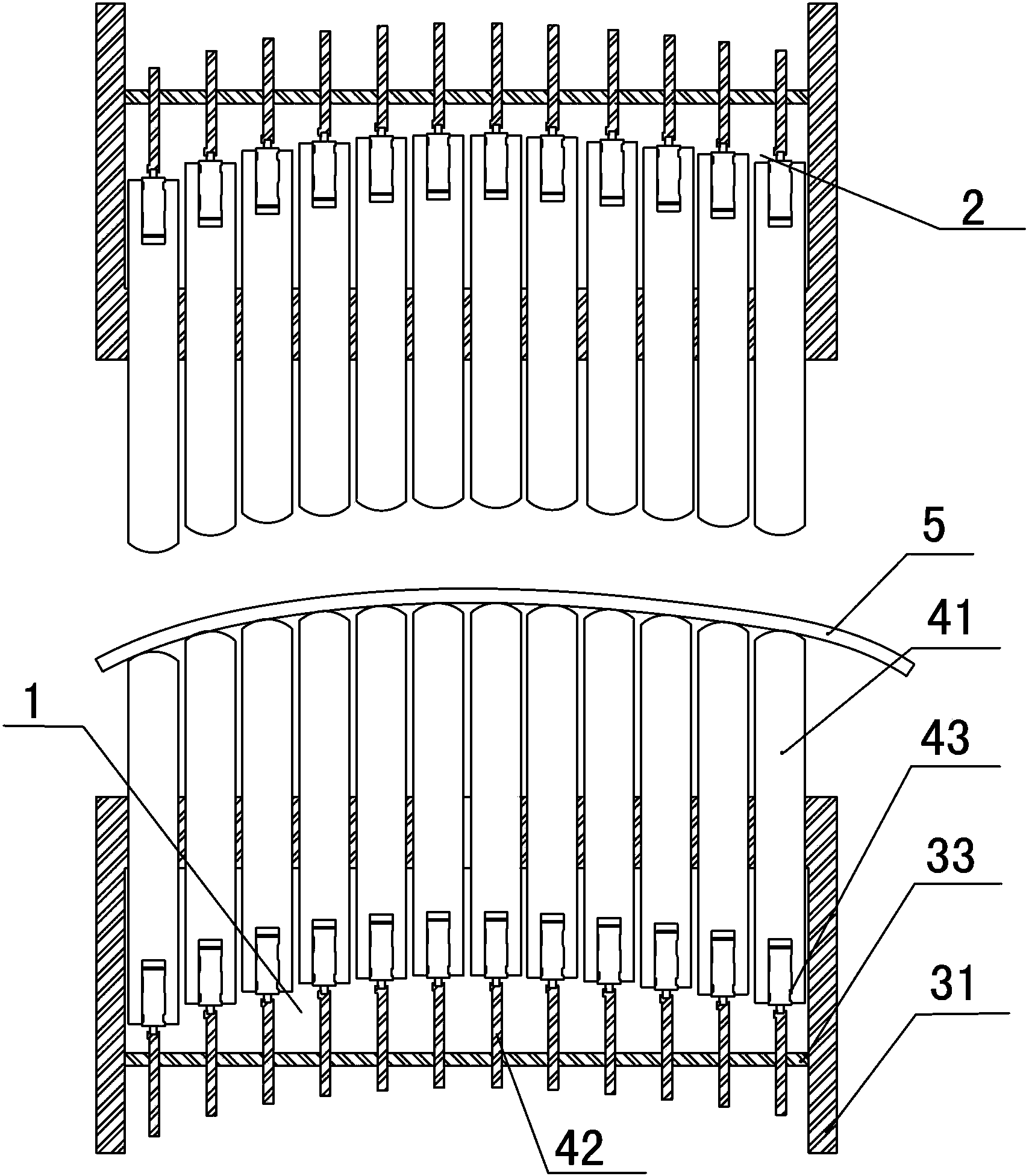

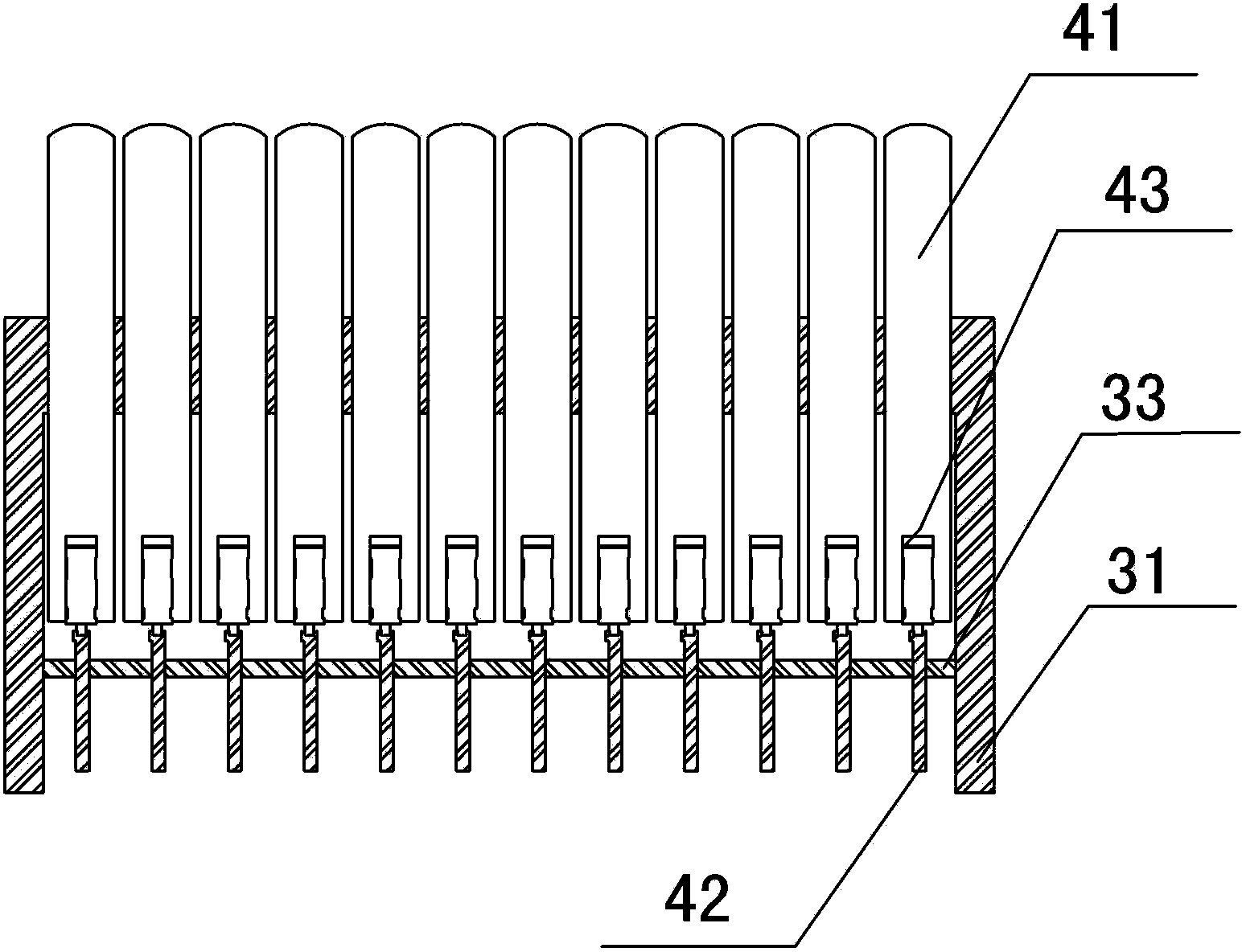

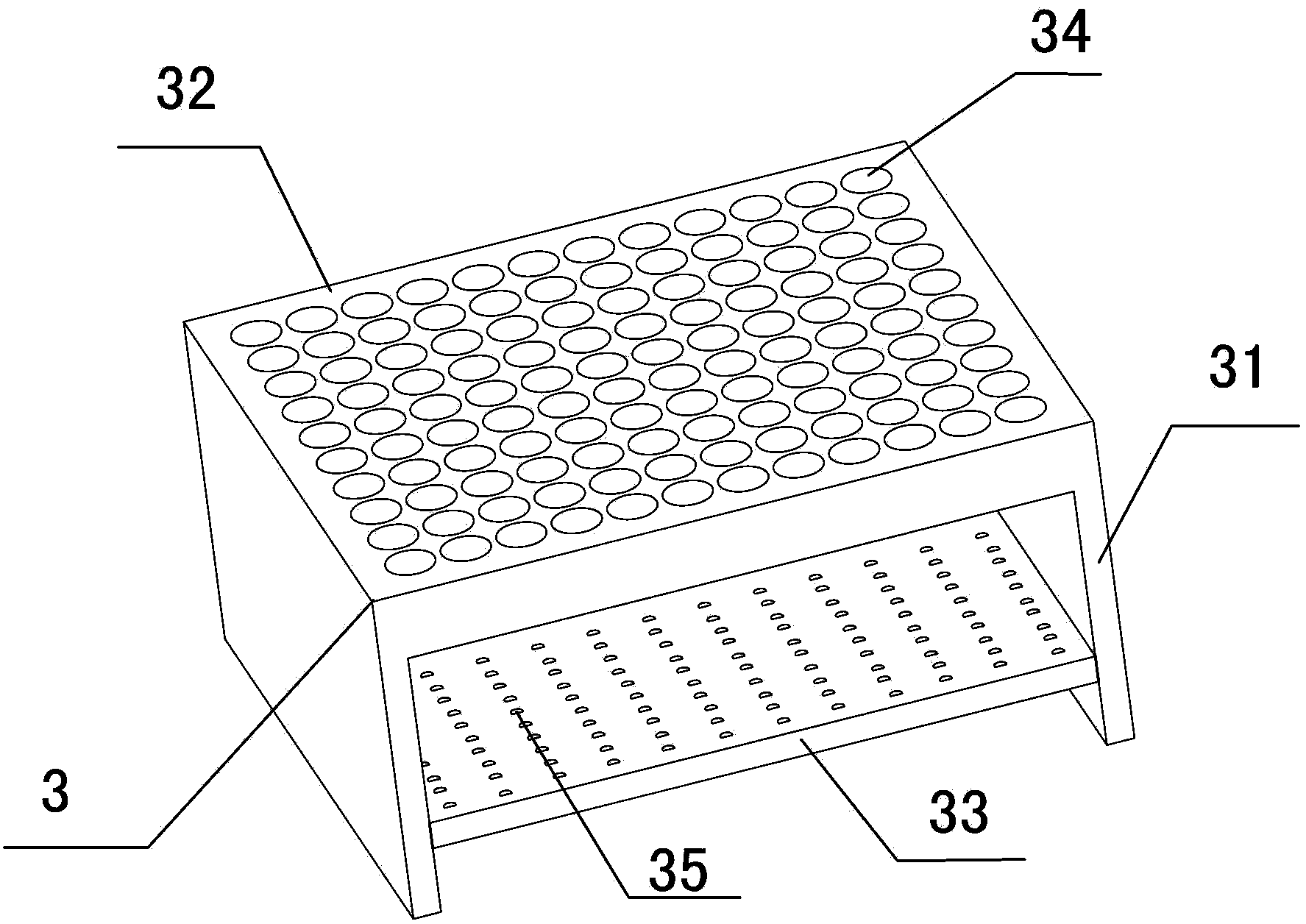

[0022] Embodiment one: if Figure 1~6 As shown, a reconfigurable mold includes a first module 1 and a second module 2 arranged symmetrically up and down, the first module 1 includes a base 3 and a plurality of reconfiguration units 4, and the base 3 includes a bracket 31 , the base plate 32 and the limiting plate 33, the base plate 32 and the limiting plate 33 are respectively fixed on the support 31, the base plate 32 is provided with a plurality of threaded holes 34, the limiting plate 33 is provided with a plurality of limiting holes 35, a plurality of The threaded holes 34 correspond coaxially to a plurality of limit holes 35. Each reconstruction unit 4 includes a screw 41, a guide rod 42 and a small motor 43. The motor body 431 of the small motor 43 is embedded in the tail of the screw 41. The screw 41 The tail end is provided with the stopper 44 of fixing small-sized motor 43, and the afterbody of screw rod 41 is threadedly connected with threaded hole 34, and the motor ...

Embodiment 2

[0028] Embodiment two: if Figure 7 As shown, a reconfigurable mold includes a first module 1 and a second module 2 symmetrically arranged left and right, the first module 1 includes a base 3 and a plurality of reconfiguration units 4, and the base 3 includes a bracket 31 , the base plate 32 and the limiting plate 33, the base plate 32 and the limiting plate 33 are respectively fixed on the support 31, the base plate 32 is provided with a plurality of threaded holes 34, the limiting plate 33 is provided with a plurality of limiting holes 35, a plurality of The threaded holes 34 correspond coaxially to a plurality of limit holes 35. Each reconstruction unit 4 includes a screw 41, a guide rod 42 and a small motor 43. The motor body 431 of the small motor 43 is embedded in the tail of the screw 41. The screw 41 The tail end is fixedly provided with the block 44 of fixing small-sized motor 43, and the afterbody of screw rod 41 is threadedly connected with threaded hole 34, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com