Front brush auxiliary device for vacuum cleaner

A technology for vacuum cleaners and attachments, which is applied in the direction of vacuum cleaners, suction nozzles, applications, etc., and can solve problems such as the vacuum cleaner tilting to the right or left

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

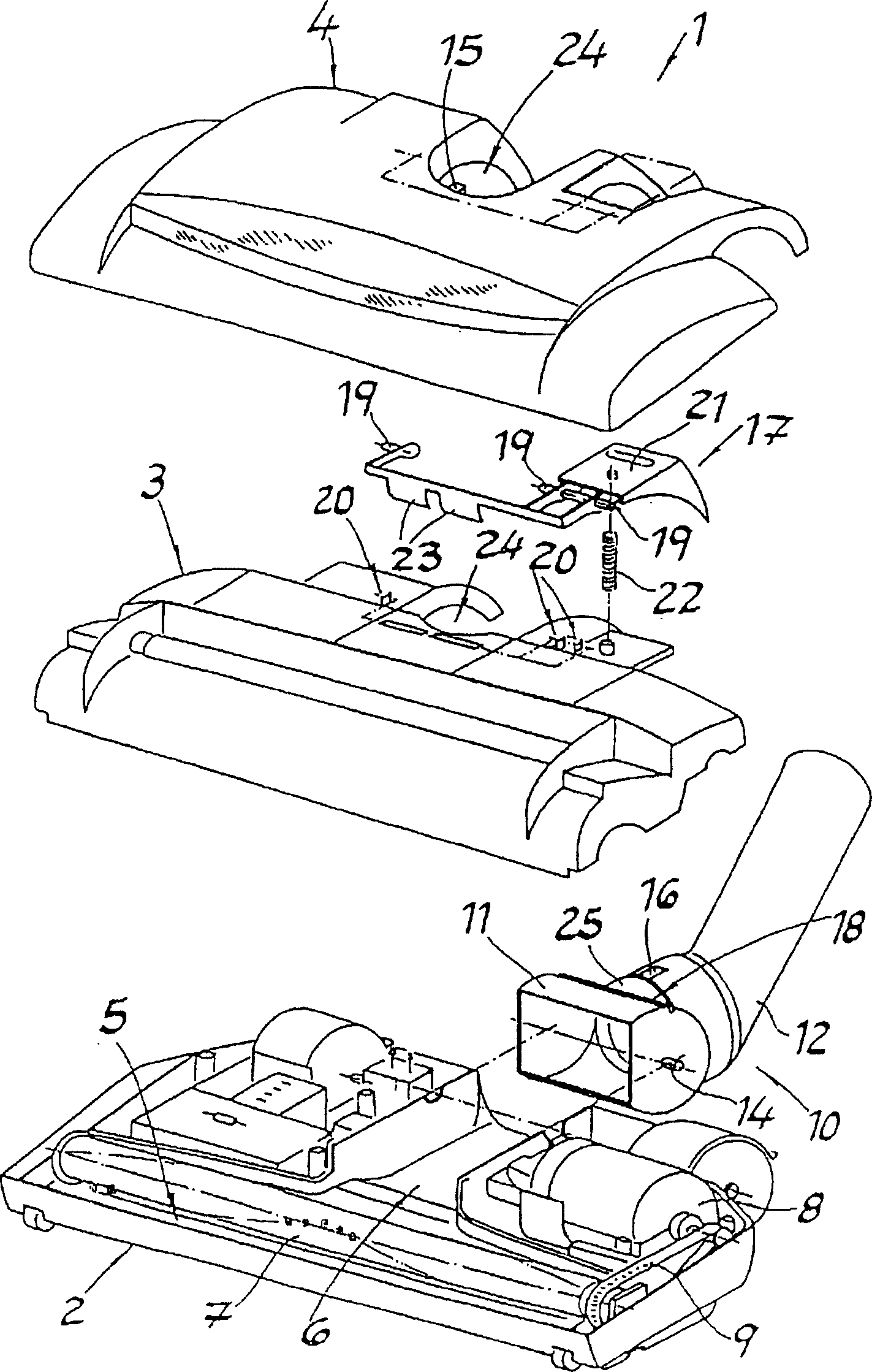

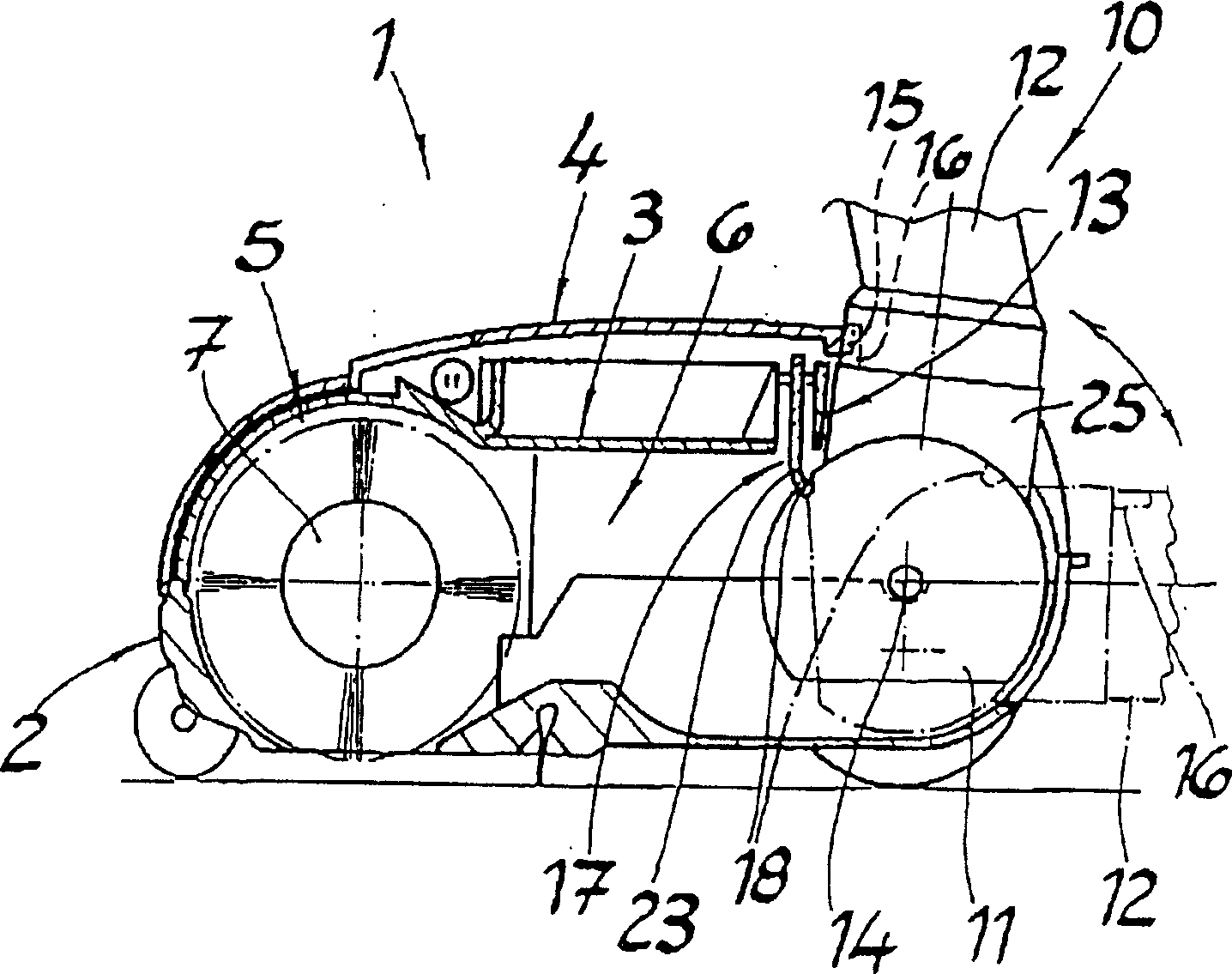

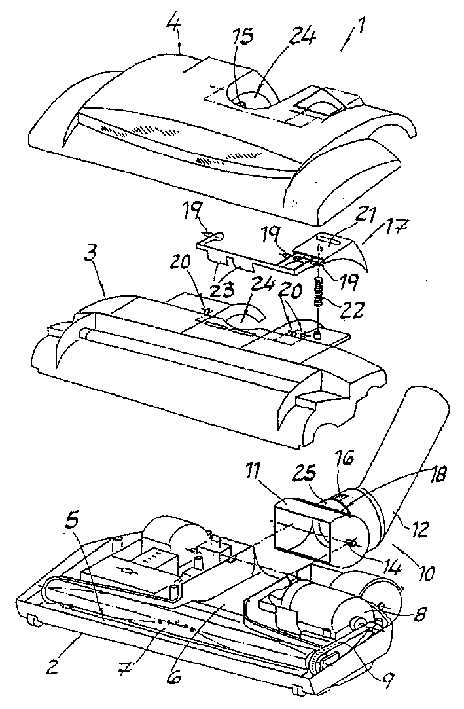

[0017] Referring now to the accompanying drawings in detail, figure 1 A front brush attachment comprising a multi-part housing 1 in the form of a suction head is shown. The housing 1 has a chassis 2 , an upper part 3 which is fixedly connected to the chassis 2 and a cover 4 which extends over the upper part 3 . The housing 1 comprises a brush roller chamber 5 which is open at its bottom and a dust suction channel 6 which leads into the brush roller chamber 5 . The dust suction channel 6 and the brush roller chamber 5 are formed by the walls of the upper part 3 and the chassis 2 . A brush roller 7 is rotatably supported in the brush roller chamber 5 . The brush roller 7 is driven by an electric motor 8 via a toothed belt 9 .

[0018] A connecting device connects the vacuum cleaner to the casing 1 . The connecting device is a rotating and pivoting joint 10 . The pivoting and pivoting joint 10 has a pivoting joint part 11 which is inserted into the suction duct 6 . The swiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com