Metallic material irradiation device used in reactor

An irradiation device and metal material technology, which is applied in the field of research on the irradiation performance of reactor materials, can solve the problems of high cost, high difficulty, and can not meet the needs of standard samples of irradiation reactors, and achieves the effect of simple structure and consistent temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

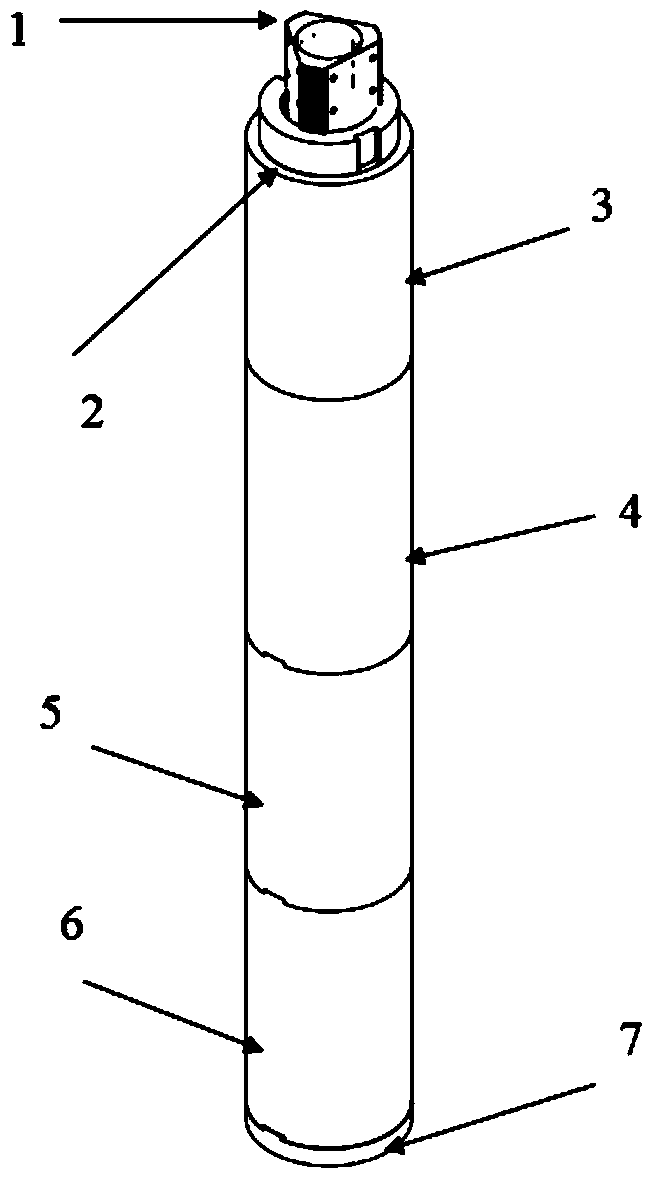

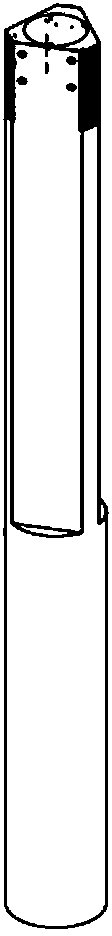

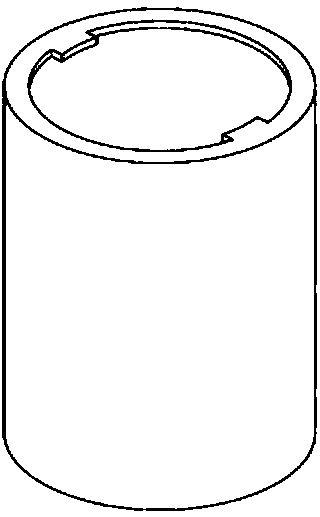

[0026] A metal material irradiation device used in a reactor, the device is used in the field of reactor engineering, as shown in the accompanying drawings, it includes a packaging sleeve 3, a sample sleeve, a mandrel 1, a base 7 and a gland 2; The packaging sleeve 3 and the sample sleeve are both hollow cylinders with the same diameter, wherein the packaging sleeve 3 is located above the sample sleeve and connected to the sample sleeve through a slot; The tube 4, the middle sub-sleeve 5, and the lower sub-sleeve 6 are three sub-sleeves, and they are assembled together through the card slots from top to bottom. Among them, the size and structure of the middle split casing 5 and the lower split casing 6 are the same, and the length of the split casing is consistent with the length of the standard sample; the inside of the middle split casing 5 and the lower split casing 6 are provided with 12 Distributed bumps that can place standard samples; 3 evenly distributed bumps that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com