Kaplan turbine blade machining equipment based on ship

A type of water turbine and processing equipment technology, applied in the field of ships, can solve the problems of large blade weight error, difficult follow-up processing, and residual impurities in the blade, and achieve the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

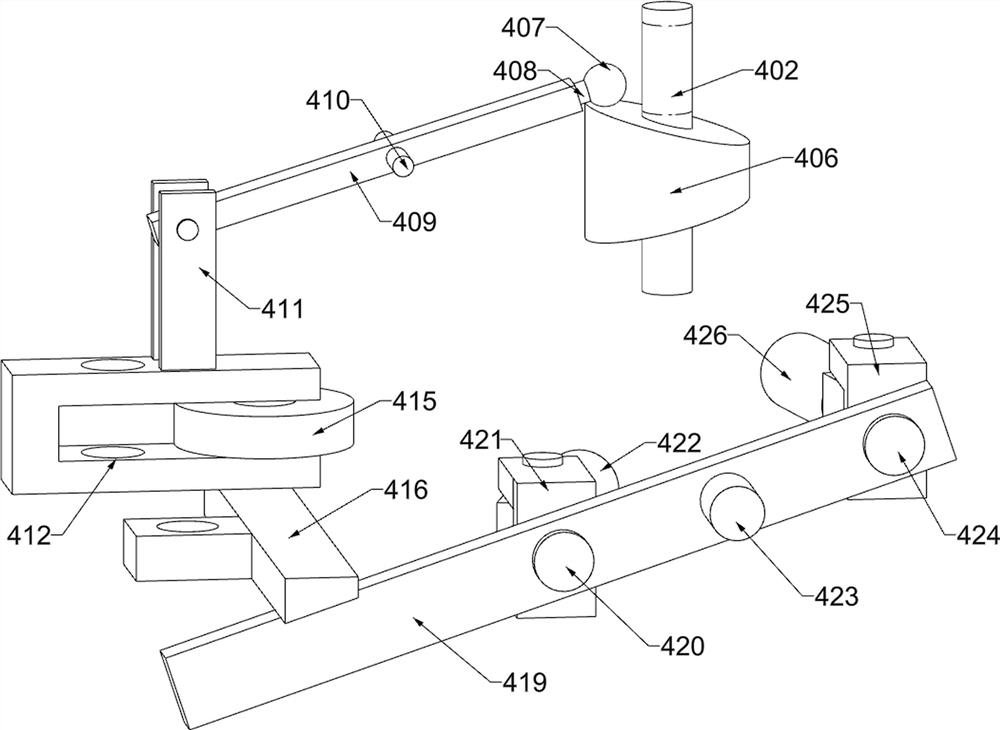

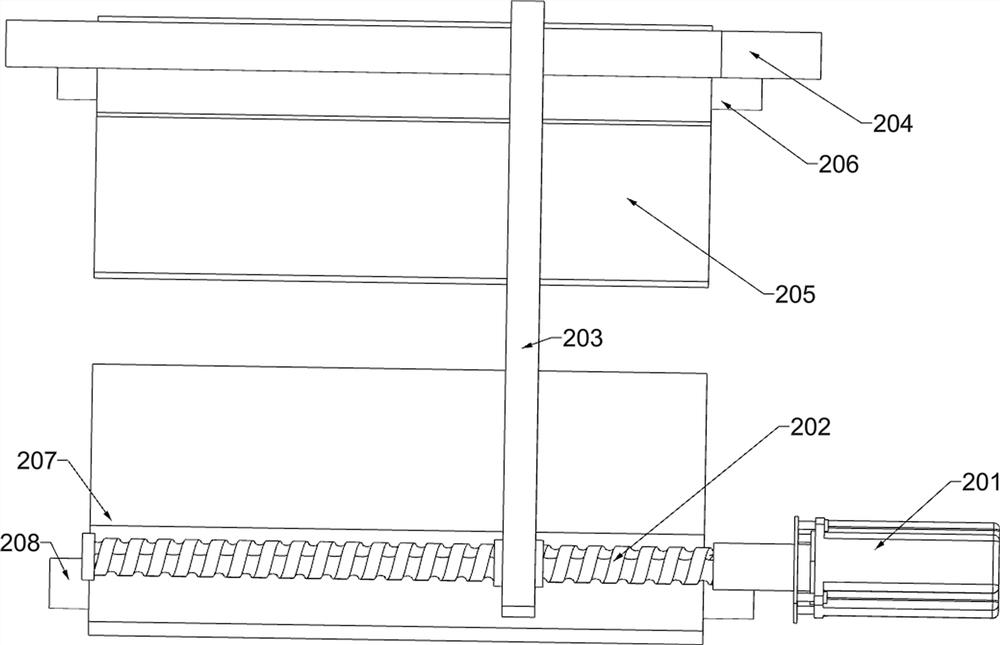

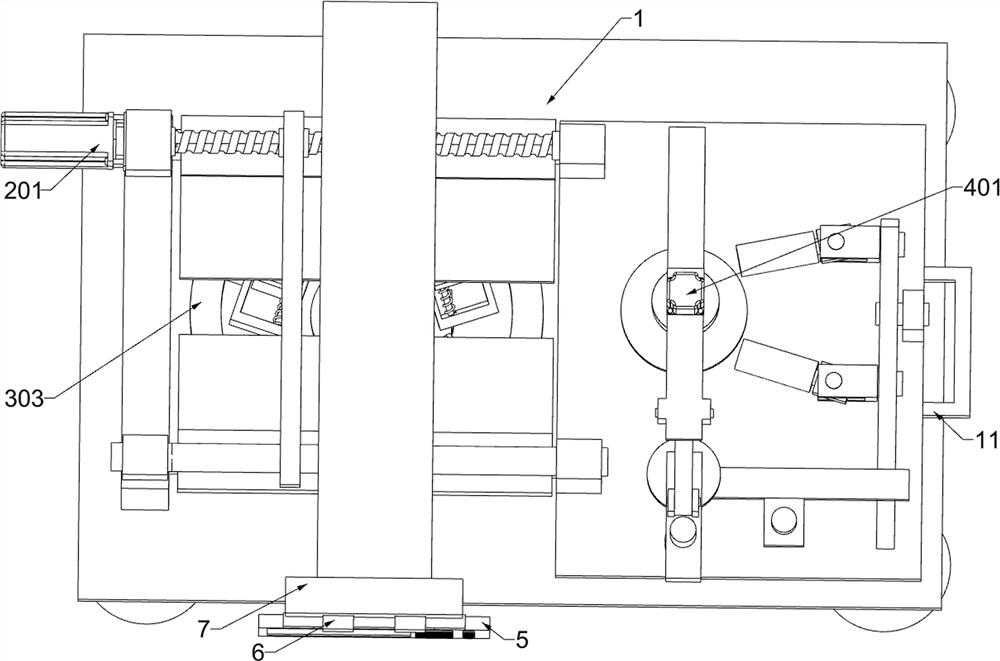

[0031] A ship-based paddle turbine blade processing equipment, according to Figure 1-3 As shown, it includes a bottom plate assembly 1, a transmission unit, a cleaning unit, a grinding unit, a control panel 5, a connector 6, a support plate 7, a foot 8, an anti-skid pad 9, a collection box 10 and a handle 11; the bottom plate assembly 1 and the transmission unit Perform rotational connection; bottom plate assembly 1 is fixedly connected to the cleaning unit; bottom plate assembly 1 is fixed to the grinding unit; bottom plate assembly 1 is fixed to the support plate 7; bottom plate assembly 1 is fixed to four sets of feet 8; bottom plate assembly 1 A collection box 10 is arranged in the middle; the support plate 7 is connected to the connector 6 in rotation; the connector 6 is fixedly connected to the control panel 5; Fixing; the cleaning unit removes the impurities remaining on the upper and lower sides of the blade, and the grinding unit grinds the outer contour and both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com