Clothing fabric three-line serging and splicing process

A technology for fabrics and garments, applied in the field of three-line stitching and splicing of garment fabrics, can solve the problems of uncomfortable wearing, easy to rub the skin, poor consumer experience, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

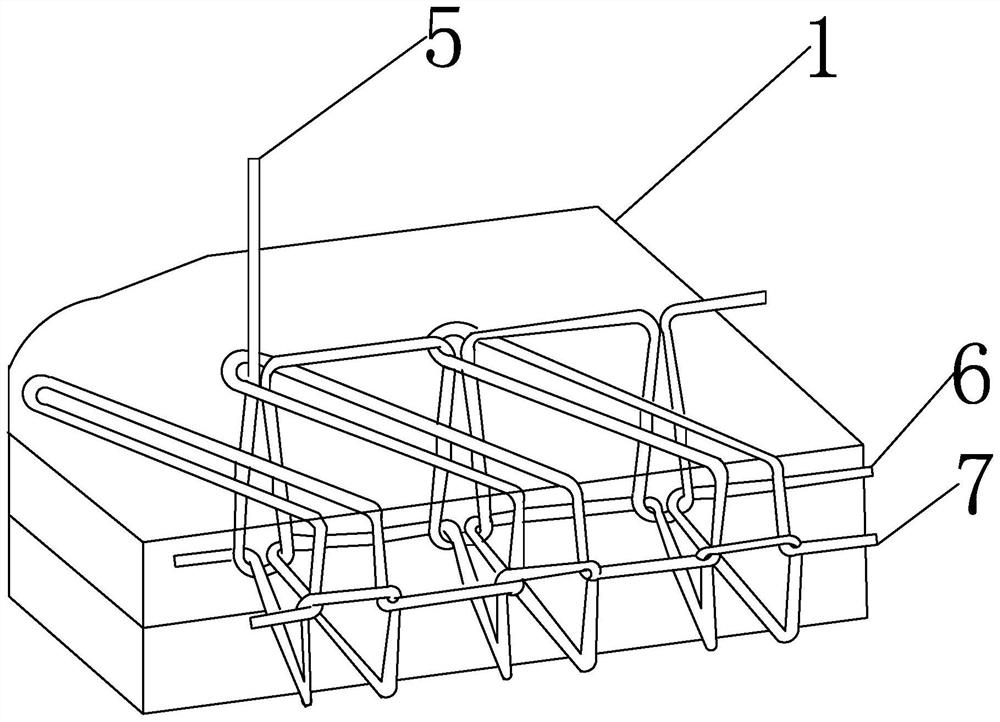

[0020] A three-line overlay splicing process for garment fabrics, characterized in that it comprises the following steps:

[0021] a. The two garment fabrics 1 to be spliced are tiled and overlapped in such a way that the front side is close to the front side;

[0022] b. Align the overlapping clothing fabrics 1 along one side;

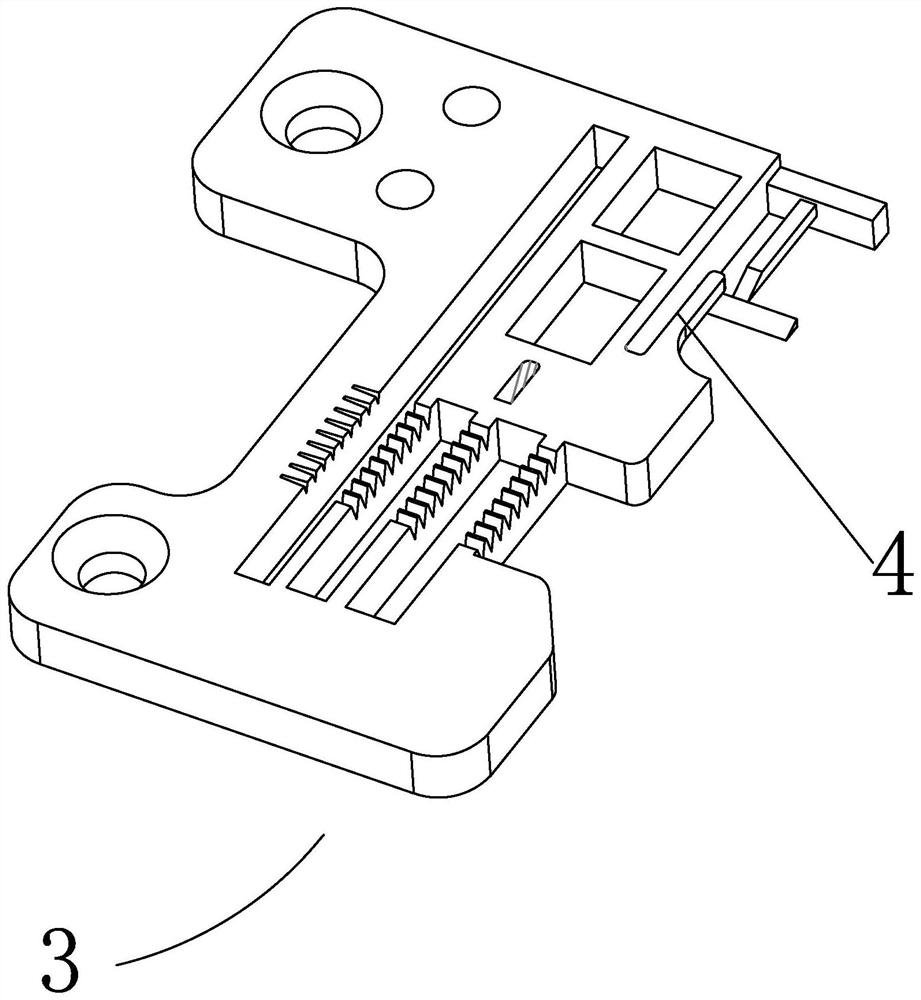

[0023] c. Use a three-thread overlock machine to sew the alignment of the garment fabric 1 to form a seam 2; the seam 2 is interspersed with the vertical needle thread 5, the lower looper thread 6, and the upper horizontal needle thread 7 to form a continuous chain Stitches: the width of the tongue 4 of the needle plate on the needle plate 3 of the three-thread overcoating machine is 0.5 mm. Adjust the thread tensioner of the three-thread overcoating machine so that the thread tensions of the vertical needle thread 5, the lower looper thread 6, and the upper horizontal needle thread 7 controlled by the thread tensioner are: vertical needle thread 5...

Embodiment 2

[0026] This embodiment provides a three-line overlay splicing process for garment fabrics, including:

[0027] a. The two garment fabrics 1 to be spliced are tiled and overlapped in such a way that the front side is close to the front side;

[0028] b. Align the overlapping clothing fabrics 1 along one side;

[0029] c. Use a three-thread overlock machine to sew the alignment of the garment fabric 1 to form a seam 2; the seam 2 is interspersed with the vertical needle thread 5, the lower looper thread 6, and the upper horizontal needle thread 7 to form a continuous chain Stitch; the needle plate tongue 4 on the needle plate 3 of the three-thread overcoating machine has a width of 1 mm; adjust the thread tensioner of the three-thread overcoating machine so that the vertical needle thread 5, the lower looper thread 6, and the upper horizontal needle thread controlled by the thread tensioner The relationship between the thread tension of 7 is: vertical needle thread 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com