Cotton kneading machine for textile processing

A cotton kneading machine and frame technology, which is applied to textiles and papermaking, fabric kneading/softening treatment, non-woven fabrics, etc., can solve the problems of low cotton kneading efficiency and failure to keep up with production, so as to reduce energy consumption, Improve the efficiency of kneading cotton and stabilize the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

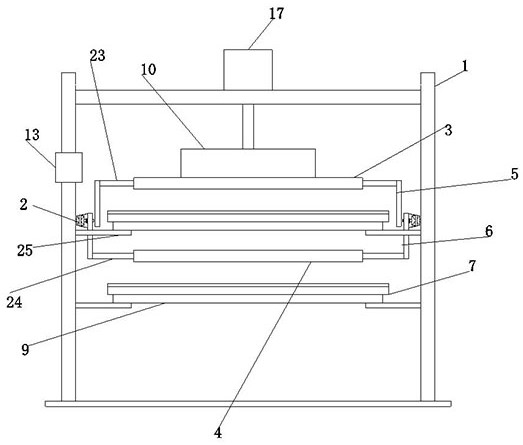

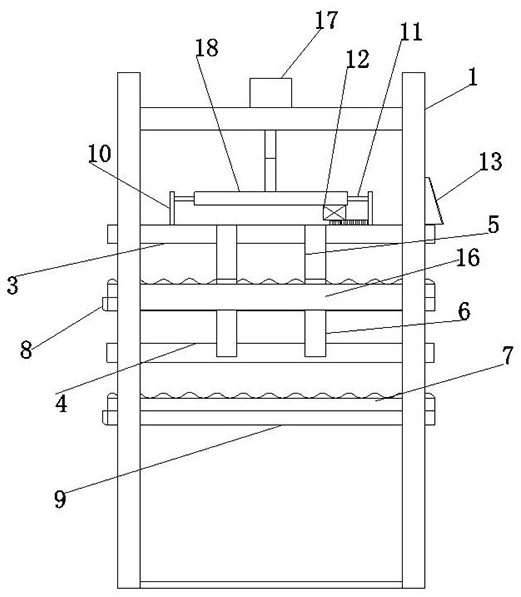

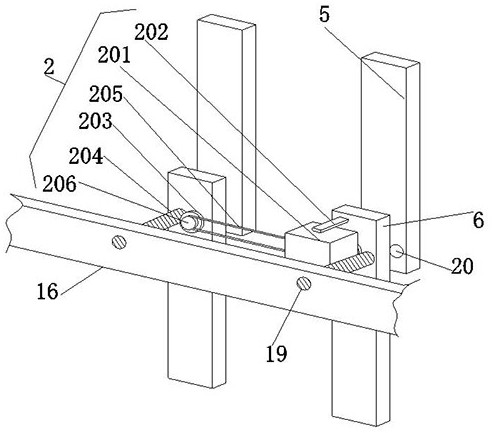

[0035] Such as figure 1 , figure 2 , image 3Shown, a kind of high-efficiency kneading cotton machine for textile processing comprises a frame 1, the first upper kneading plate 3, the second upper kneading plate 4 and a bearing plate 9, and a cylinder 17 is fixedly installed in the center of the top of the frame 1, so that The output shaft of the cylinder 17 is movable through the top of the frame 1 and is fixedly connected with the lifting plate 18. The lifting plate 18 is driven up and down by the cylinder 17, and is used to drive the upper kneading plate to descend to carry out the kneading operation. The lifting plate 18 is horizontally interspersed with two A slide bar 11, the two ends of the slide bar 11 are all fixedly connected on the side fixed bar 10, and the side fixed bar 10 on the first upper kneading plate 3 is connected by the lifting plate 18 through the slide bar 11, so that the first upper kneading plate 3 is connected. The kneading plate 3 rises and falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com