Preparation method of node-reinforced double-net type filter screen

A node and filter technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of easy wear or even breakage, filter damage, expansion, etc., to improve the filtering effect, prolong the service life, avoid wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

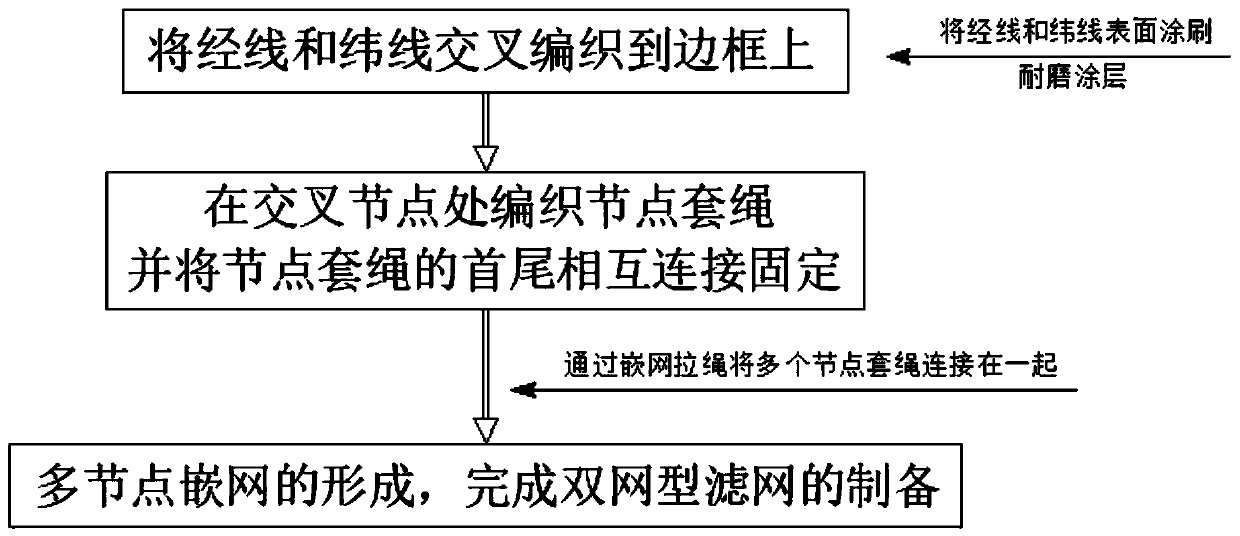

[0047] see figure 1 , a method for preparing a node-reinforced double-screen filter screen, comprising the following steps:

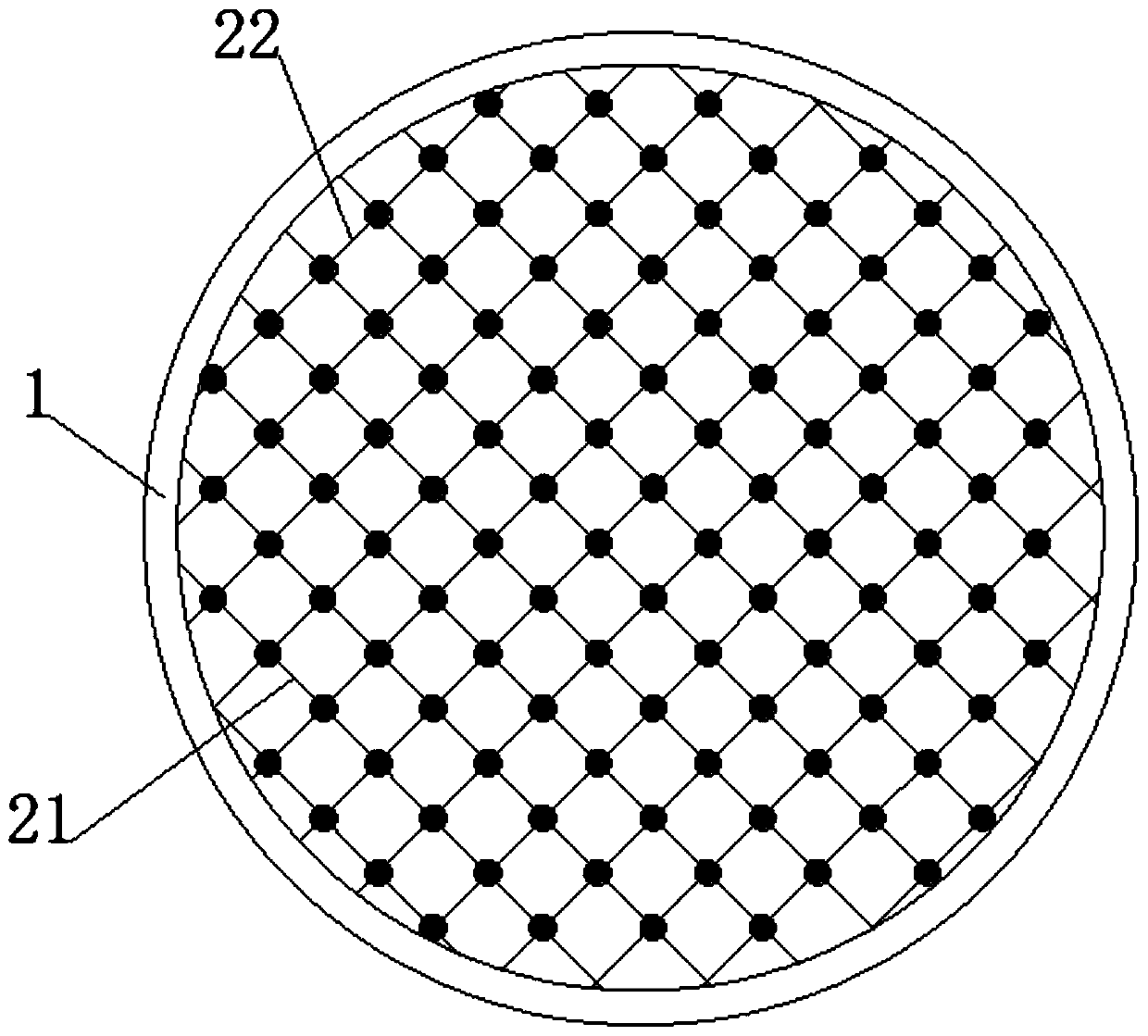

[0048] S1, see figure 2 1. Firstly, the surface of the warp 21 and the weft 22 is coated with a wear-resistant coating, and after drying, the warp 21 and the weft 22 are cross-woven onto the frame 1;

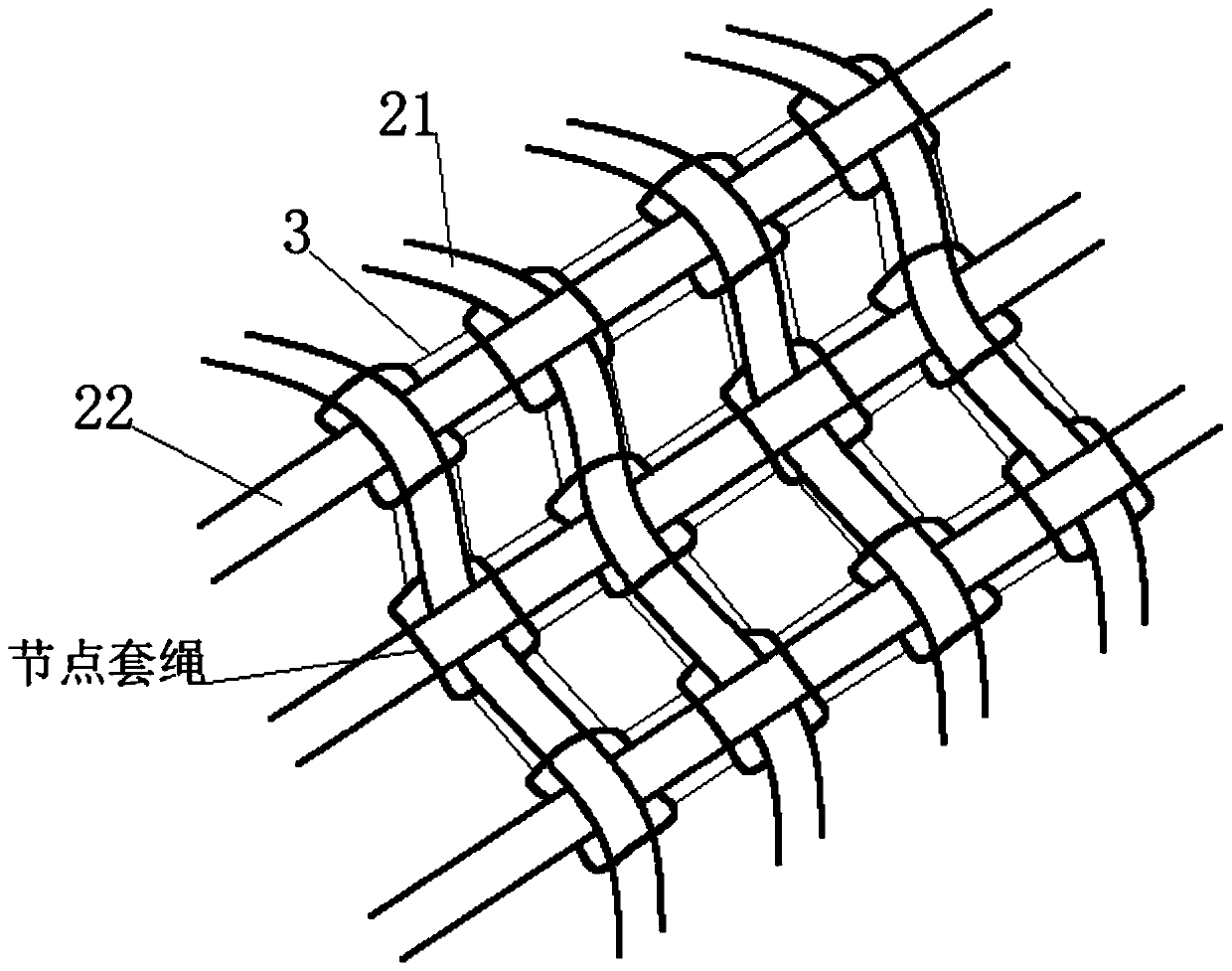

[0049] S2. Please refer to image 3 , knitting nodal nooses at the intersection nodes of each warp 21 and weft 22, and connecting the ends of the nodal nooses to each other and fixing them;

[0050] S3, see Figure 4 , the formation of multi-node embedding, connecting two embedding ropes 3 between vertically and horizontally adjacent node ropes, so that the node ropes at multiple nodes are connected as a whole, forming a multi-node embedding between the filter screens Net to complete the preparation of the double mesh filter.

[0051] see Figure 5 , the multi-node sleeve rope includes a circumferential limit rope 41, and a longitudinal limit rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com